Prefabricated part of wind power blade root, blade root part, blade and manufacturing method thereof

A technology for wind power blades and a manufacturing method, which is applied to the field of prefabricated parts for wind power blade roots, can solve problems such as difficult assembly and production of embedded parts, and achieve the effects of facilitating standardized management, reducing difficulty and time, and easily controlling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

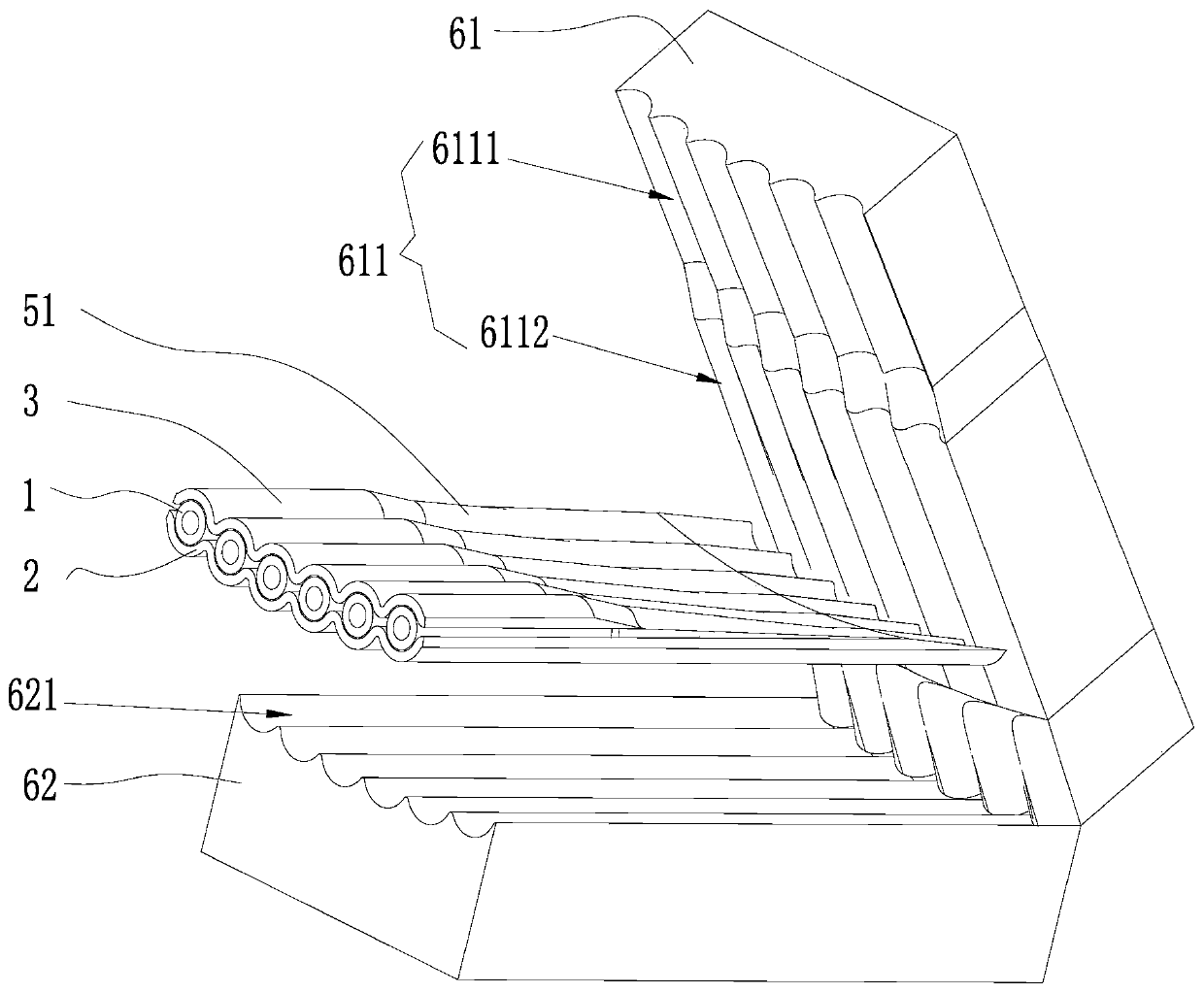

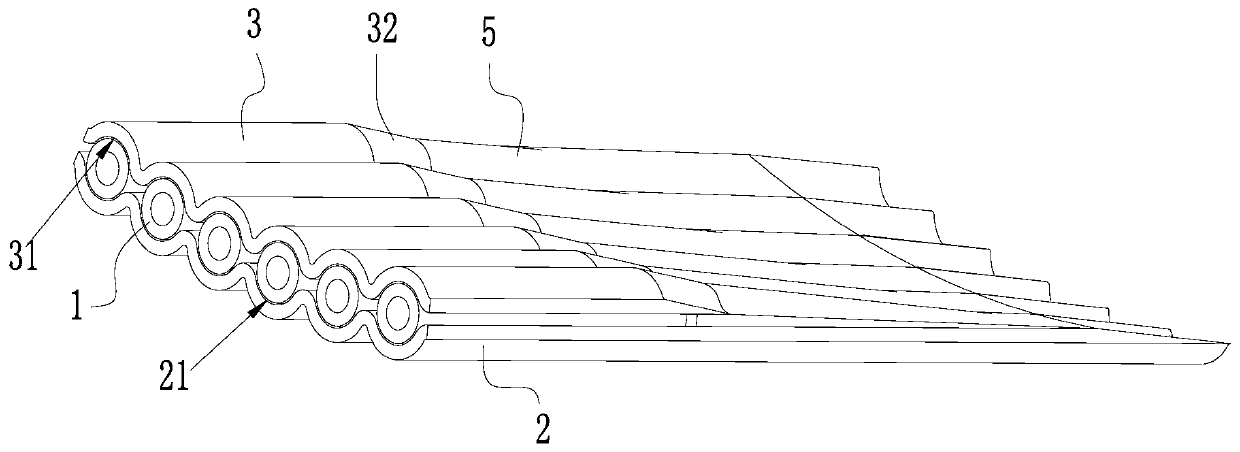

[0043] Please also refer to Figure 1 to Figure 5 , the production method of the wind power blade root prefabricated part provided by the present invention will now be described. The production method of the wind power blade root prefabricated part comprises the following steps:

[0044] S1. Preform the upper substrate 3 and the lower substrate 2, the upper substrate 3 and the lower substrate 2 are both a sheet, and the lower substrate 2 is provided with some first grooves 21;

[0045] S2. Place the lower matrix 2 in the mold 6, place several embedded parts 1 in the first groove 21, fasten the upper matrix 3 onto the embedded parts 1, and The first groove 21 and the second groove 31 are arranged opposite and surround the outside of the embedded part 1;

[0046] S3. Coating adhesives on the lower substrate 2 and the upper substrate 3 respectively, and bonding with the embedded part 1, so that the upper substrate 3, the embedded part 1 and the lower substrate 2 can be bonded ...

specific Embodiment approach

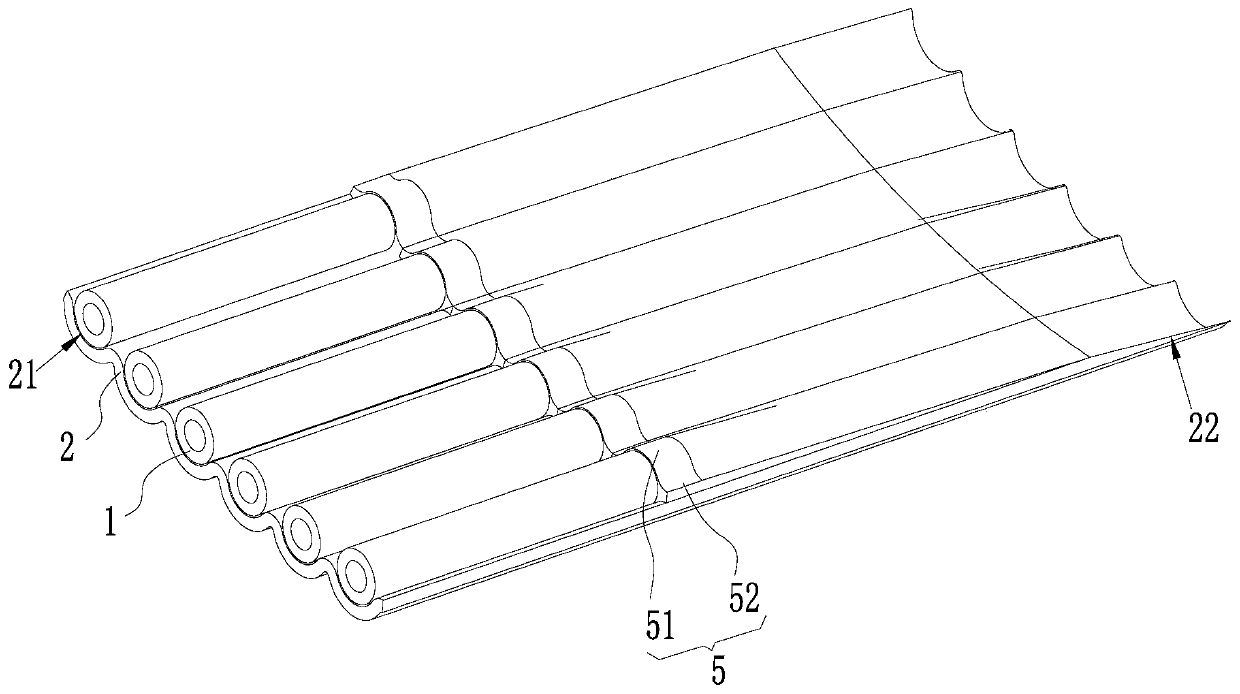

[0061] Further, see image 3 , as a specific implementation of the wind power blade root prefabricated part production method provided by the present invention, it also includes the following steps:

[0062] S3.1 After the embedded part 1 is placed in the first groove 21, a filling part 5 is arranged on one side of the embedded part 1, and the filling part 5 is in contact with the embedded part 1 spliced and embedded in the first groove 21 together. Specifically, the filler 5 is generally made of foam or other light material that can be filled, and it is also arranged in the first groove 21. The filler 5 includes a The filling rod 51 and the filling lugs 52 arranged on opposite sides of the filling rod 51 , the filling lugs 52 of the adjacent filling pieces 5 abut against each other. The thickness of the filling rod 51 is consistent with that of the embedded part 1 , or the thickness of the filling rod 51 is greater than that of the embedded part 1 . The filling rod 51 is...

Embodiment 2

[0069] The present invention also provides another method for producing wind power blade root prefabricated parts. The difference between it and Embodiment 1 is that in step S3, the lower base body 2, the embedded part 1 and the upper layer base body 3 are stacked in advance, and then facing Adhesive is filled between the upper matrix 3 and the lower matrix 2, so that the upper matrix 3, the embedded part 1 and the lower matrix 2 can be bonded. Compared with the way of applying the adhesive multiple times in Example 1, its operation is simpler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com