Pre-dug large-section gob-side entry retaining roadway with columns built in roadway and construction method thereof

A construction method and large-section technology, applied in earth cube drilling, pillars/brackets, mining equipment, etc., can solve problems such as not being able to meet the needs of rapid advancement of the working face, affecting the production efficiency of the working face, and affecting the production efficiency of the working face. Avoid spontaneous combustion of residual coal, avoid harmful gas gushing out, and improve the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

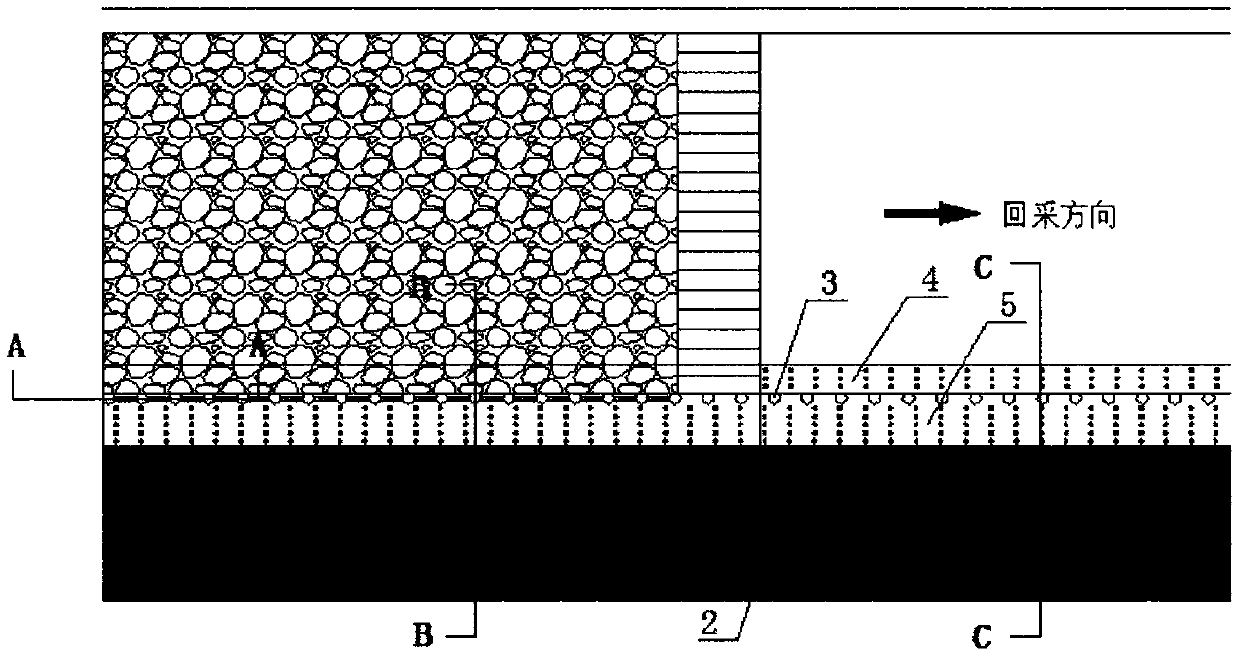

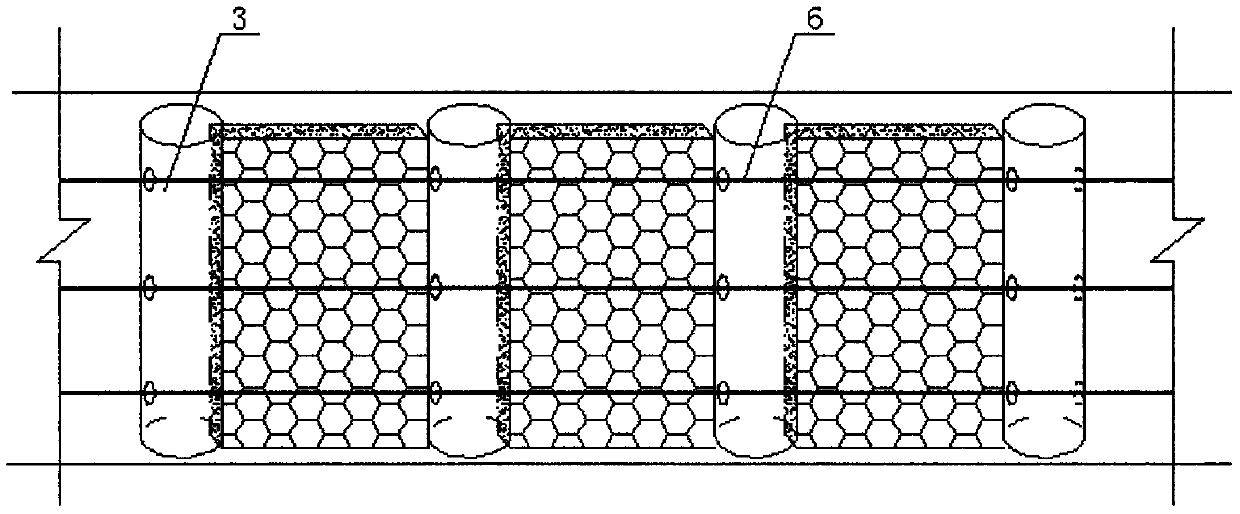

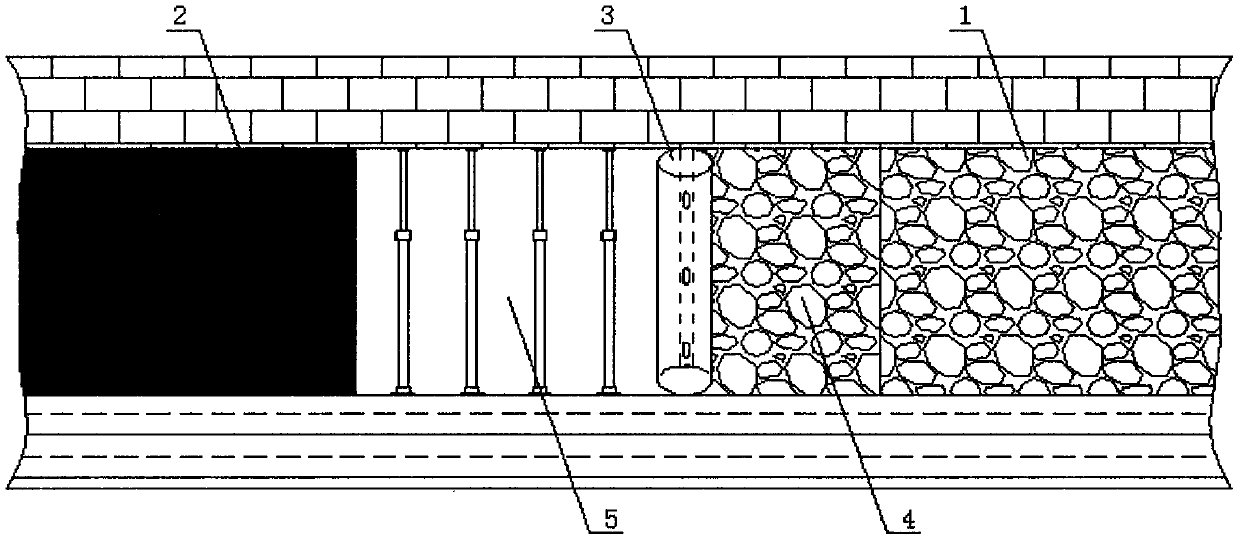

[0045] Figure 1-5 It is a preferred embodiment of the gob-side retaining roadway with pillars in the pre-excavated large-section roadway of the present invention.

[0046] In the pre-excavation large-section roadway, the pillars are built along the goaf and the roadway is arranged between the working face 1 to be mined and the adjacent working face 2, and piers 3 are built along the direction, and the two sides of the piers 3 are formed to be The coal cutting lane 4 and the reserved lane 5 of the working face, the coal cutting lane 4 of the working face to be mined is close to the working face 1 to be mined, and meets the coal cutting requirements of the working face 1 to be mined, and the width is 1-2m. Lane 5 is close to the adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com