Cantilever type vertical shaft dig anchor machine with walking mechanism

A walking mechanism and cantilever type technology, which is applied in the field of cantilever longitudinal axis bolter, can solve the problems affecting the construction efficiency and construction speed, the tension between coal mining and excavation, and the inability to realize parallel operation of digging and anchoring, so as to improve construction efficiency and The effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

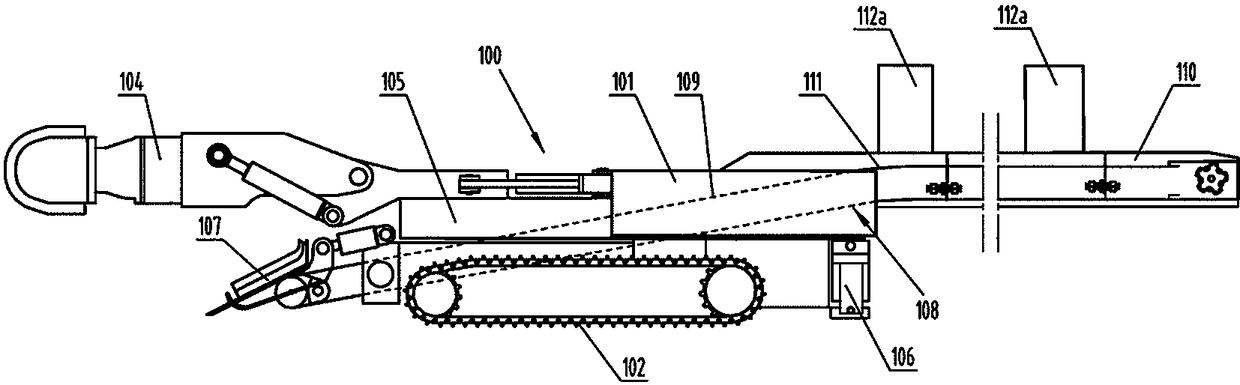

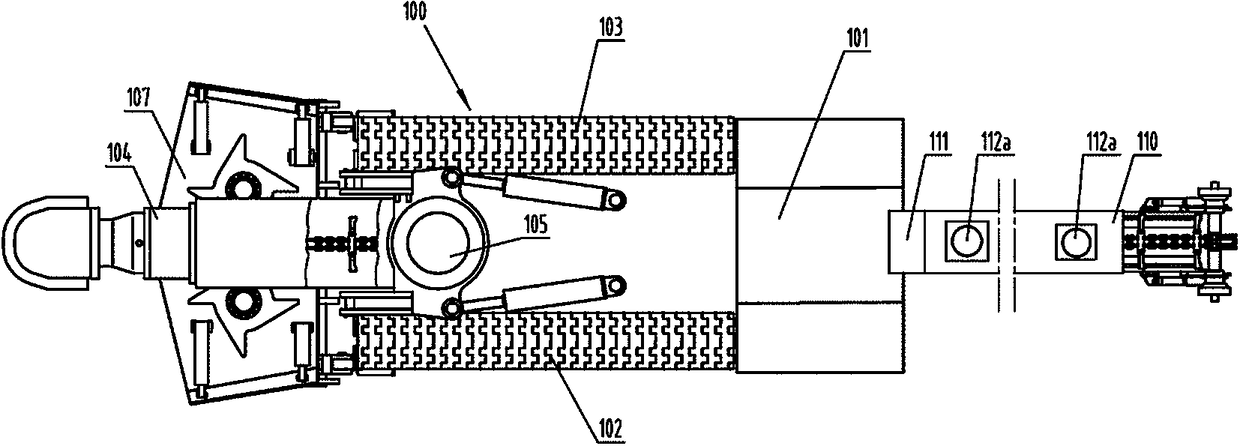

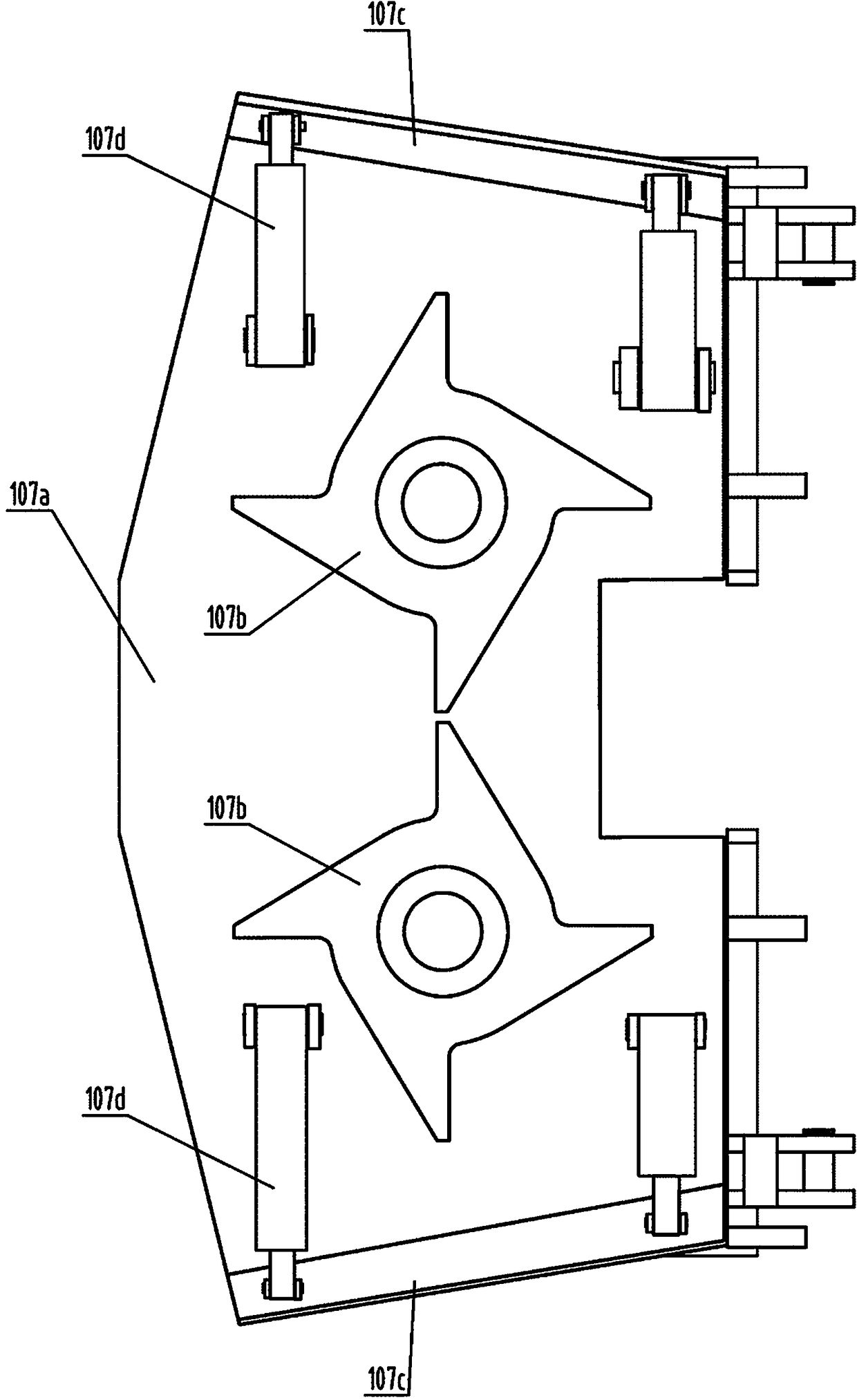

[0031] Depend on figure 1 and figure 2 It can be seen that the cantilever type longitudinal axis bolter includes: a cantilever type longitudinal axis roadheader 100, the cantilever type longitudinal axis roadheader 100 includes a frame body 101, a left walking part 102, a right walking part 103, a cutting part 104, a rotary Body 105, rear support body 106, loading mechanism 107, first scraper conveyor 108, electric control system, hydraulic system, spraying system and cooling system; first scraper conveyor 108 includes a tail part arranged on the frame body 101 109, protruding out from the machine head part 110 in the horizontal direction at the rear of the frame body 101, between the machine head part 110 and the tail part 109 is connected with an inclined slope chute 111, on the machine head part 110 is provided with several An airborne rock bolter 112a.

[0032] During use, because the first scraper conveyor 108 is stretched out on the head portion 110 of the frame body ...

no. 2 example

[0038] Depend on Figure 4 It can be seen that this embodiment is basically the same as the first embodiment, the differences are:

[0039] The first scraper conveyor 108 is provided with an elevating work platform that supports workers to facilitate their work. Of course, the elevating work platform can also be arranged between the airborne bolter rig 112a and the head part 110 as required. The platform includes a platform 114, between the platform 114 and the head part 110, a first frame body 115 and a second frame body 116 connected in the middle are provided, the top of the first frame body 115 is hingedly connected with a side part of the platform 114, and the first The bottom of the frame body 115 is slidably connected with the head part 110, the top of the second frame body 116 is slidably connected with the other side of the platform 114, and the bottom end of the second frame body 116 is hingedly connected with the head part 110. A hydraulic lift cylinder 117 is arra...

no. 3 example

[0041] Depend on Figure 5 , Figure 6 and Figure 7 It can be seen that this embodiment is basically the same as the first embodiment, the differences are:

[0042] The cantilever type longitudinal axis bolter also includes a second scraper conveyor 113, the tail end of the second scraper conveyor 113 is located below and overlaps the nose portion 110 of the first scraper conveyor 108, and the second scraper conveyor 113 The head end of the machine is overlapped with the external supporting transportation equipment; several airborne bolters 112b are arranged on the second scraper conveyor 113, and in order to facilitate the movement of the second scraper conveyor 113 on the left and right sides of the second scraper conveyor 113 The left crawler traveling mechanism 118a and the right crawler traveling mechanism 118b are respectively provided on the top; in order to enhance the safety performance, avoid the second scraper conveyor 113 from colliding with the cantilever type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com