Excavating, filling and supporting construction equipment and method

A technology for construction equipment and excavation face, which is applied in mining equipment, earthwork drilling, pillars/brackets, etc., and can solve the problems of long switching time between support and excavation operations and affecting construction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

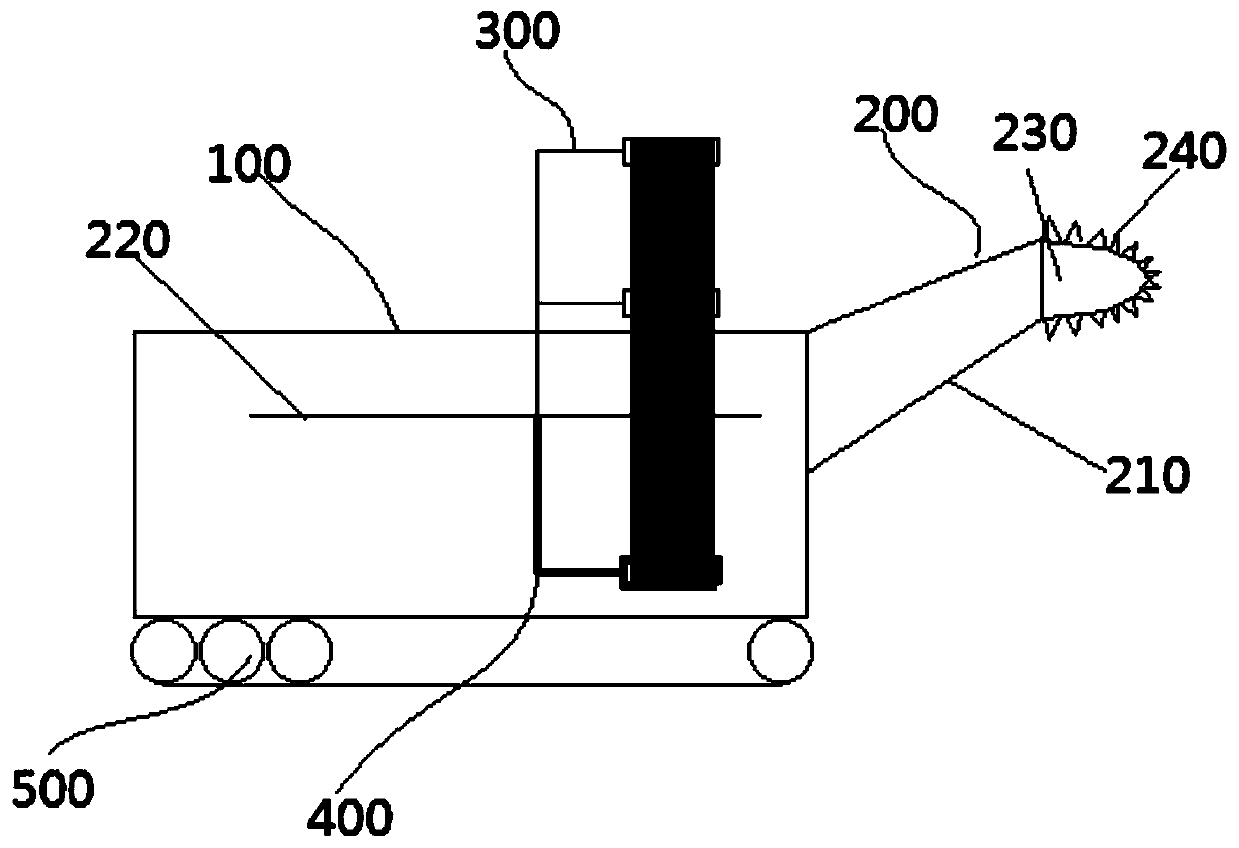

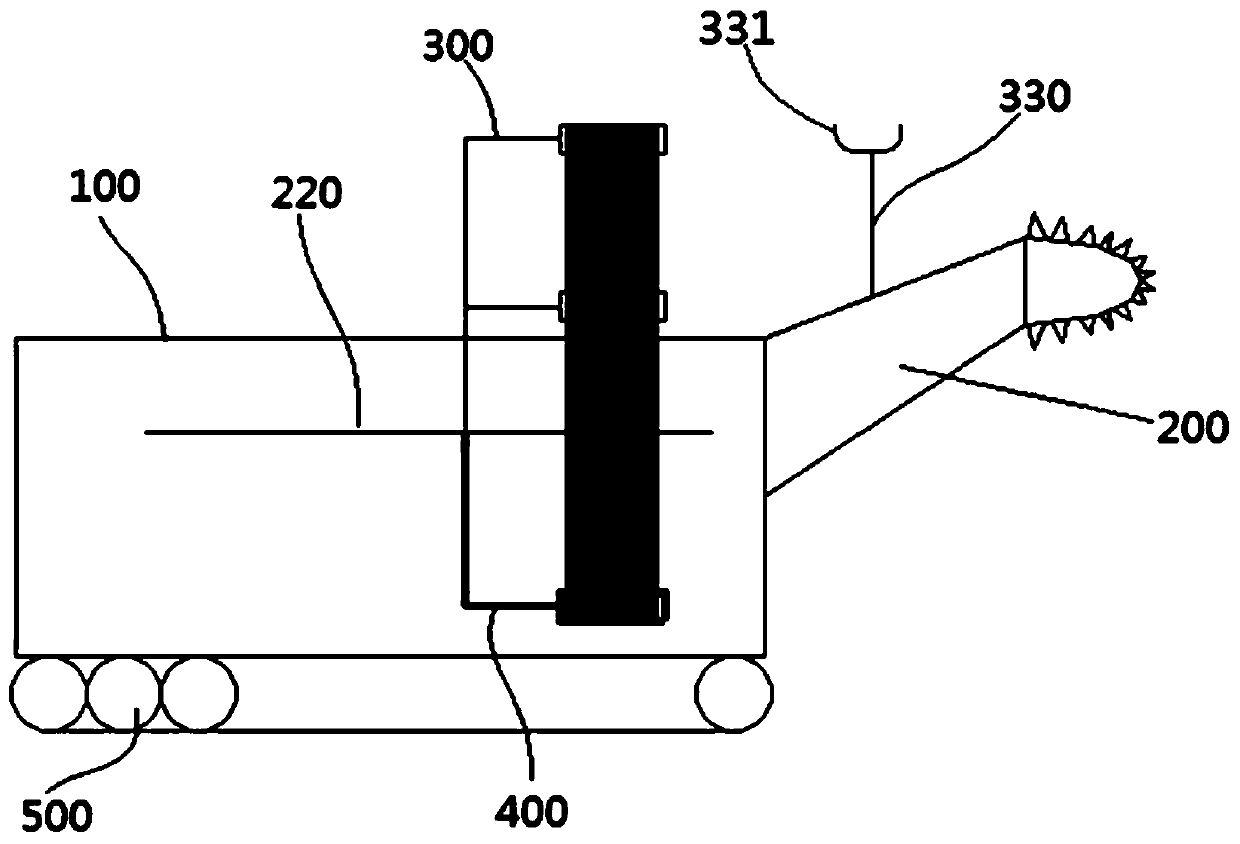

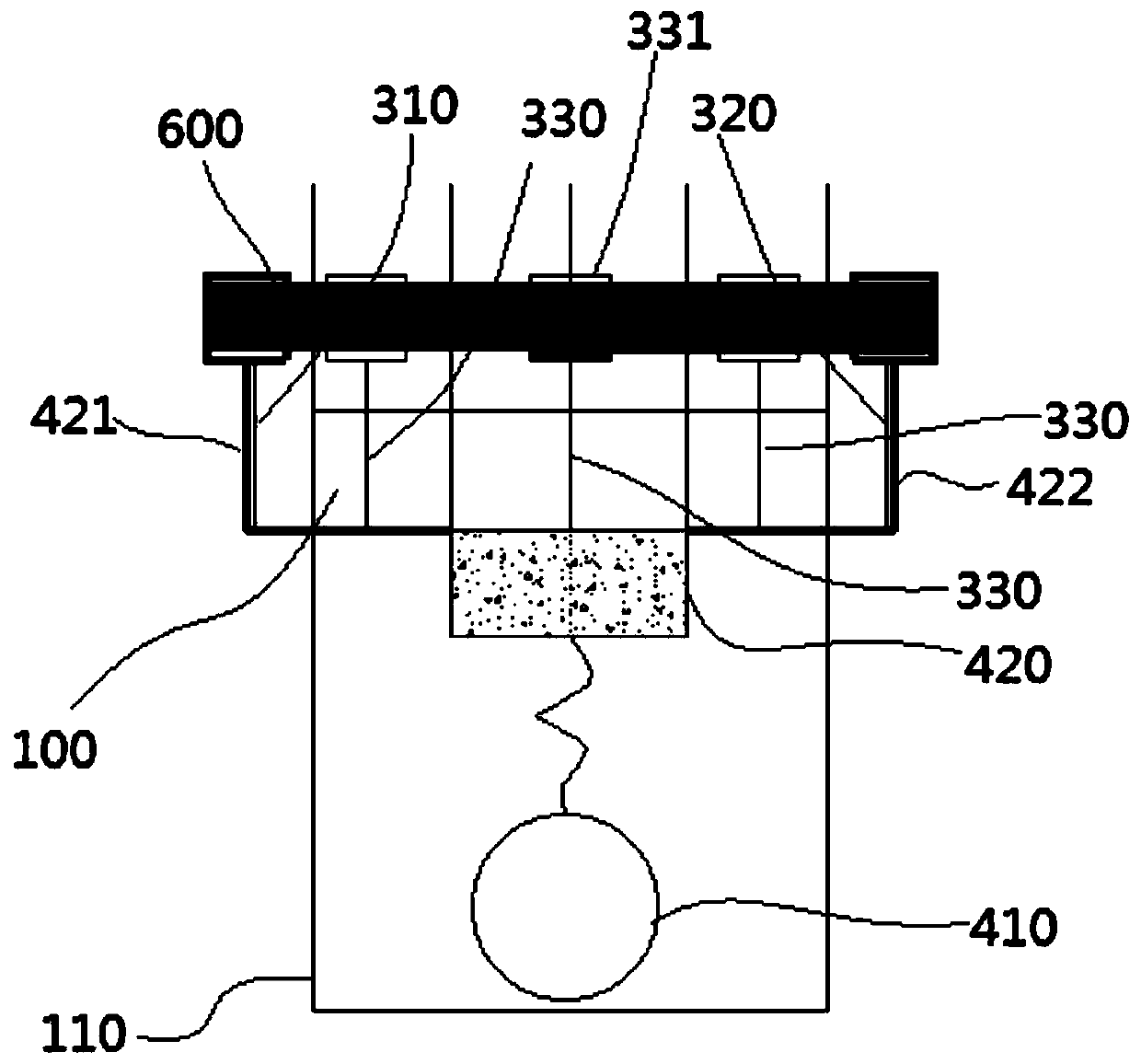

[0054] see Figures 1 to 8C As shown, the excavation perfusion support construction equipment provided by the embodiment of the present invention is suitable for excavation and support in underground spaces, the underground spaces include tunnels, roadways, etc., and the equipment includes: machine base 100, rock and soil cutting assembly 200 , the auxiliary supporting component 300 and the concrete pouring component 400 .

[0055] Wherein, the bottom of the base 100 is provided with a traveling mechanism 500, and the base 100 is provided with a hydraulic drive system (which is the prior art, not shown in the figure), and the geotechnical cutting assembly 200 is located in front of the base 100. , for cutting rock and soil, the auxiliary support assembly 300 includes a hydraulic power system and a first mechanical arm 310, a second mechanical arm 320, and a third mechanical arm 330 respectively connected to the hydraulic power system, for individually or cooperatively completi...

Embodiment 2

[0088] see Figure 1 to Figure 13 Shown, the embodiment of the present invention excavation perfusion support construction method, comprises steps:

[0089] S11. Park the excavation grouting support construction equipment in front of the working face to be excavated, and make the rock-soil cutting assembly 200 face the working face to be excavated;

[0090] S12. Start the geotechnical cutting assembly 200 to work. Driven by the hydraulic power system, the geotechnical cutting assembly 200 is stretched from the initial shrinkage state to the excavation work face. Driven by the rotating drive motor, the geotechnical cutting assembly 200 rotates as scheduled Trajectory cutting the rock and soil of the excavation face;

[0091] After cutting a groove with a predetermined outline and a predetermined depth on the excavation face, turn off the rotary drive motor, and shrink the rock-soil cutting assembly 200 to a position close to the front end of the base 100 under the drive of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com