Special aluminum square tube ceiling and construction method thereof

A suspended ceiling and special-shaped technology, applied in the direction of ceiling, building components, covering/lining, etc., can solve the problem that the aluminum square pass ceiling cannot be applied to the decorative surface of the irregular-shaped ceiling, and achieves low construction cost, simple and practical construction method, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

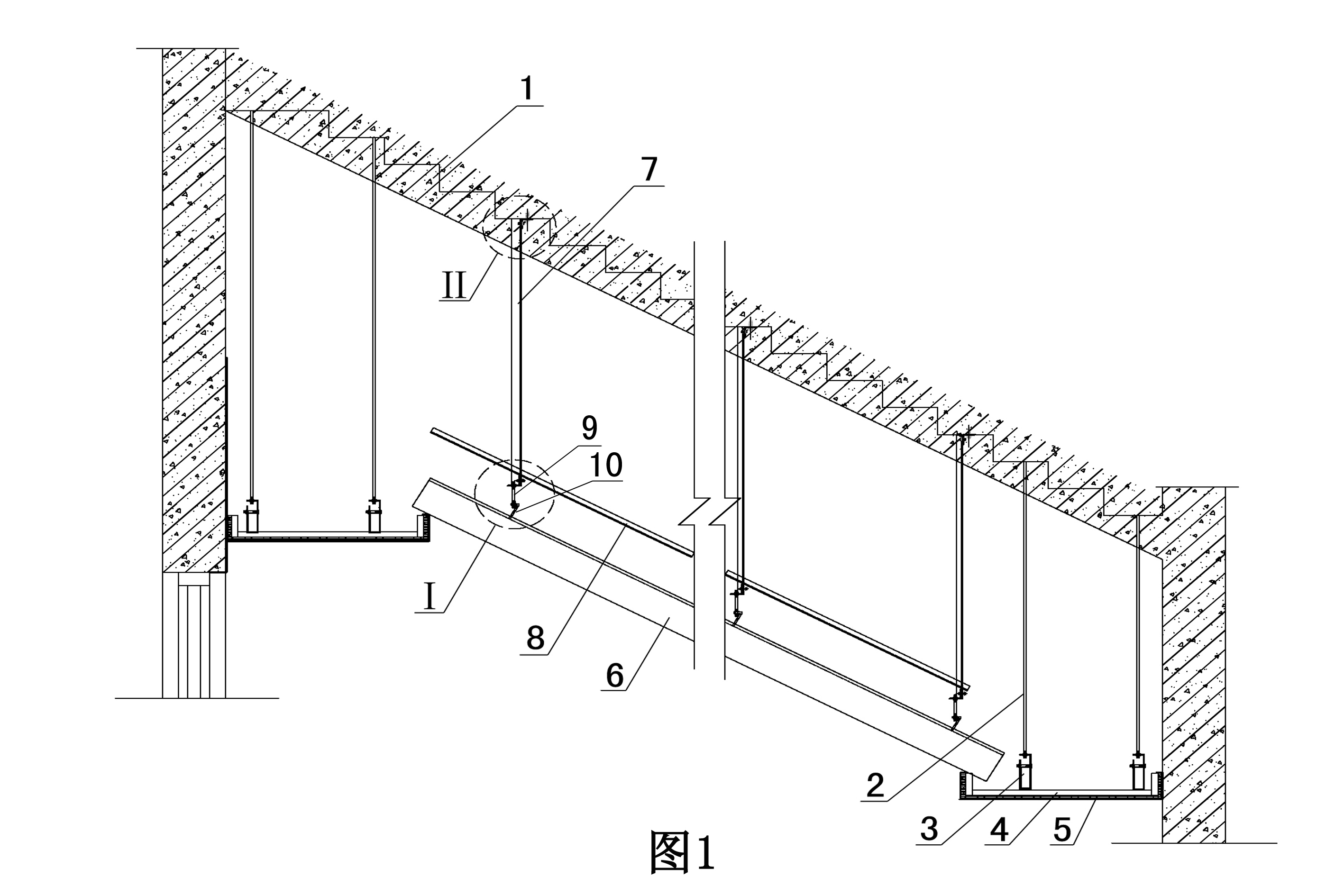

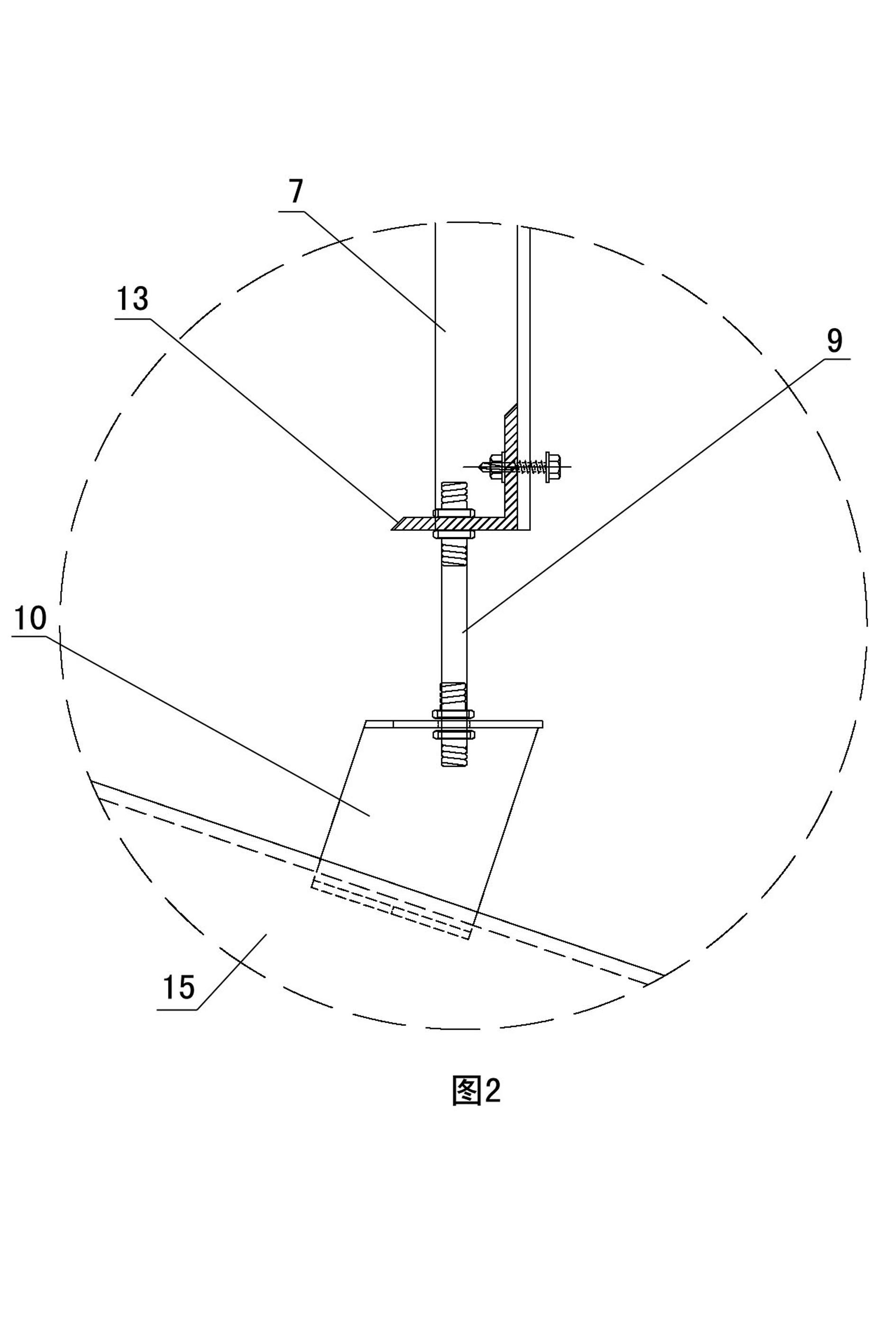

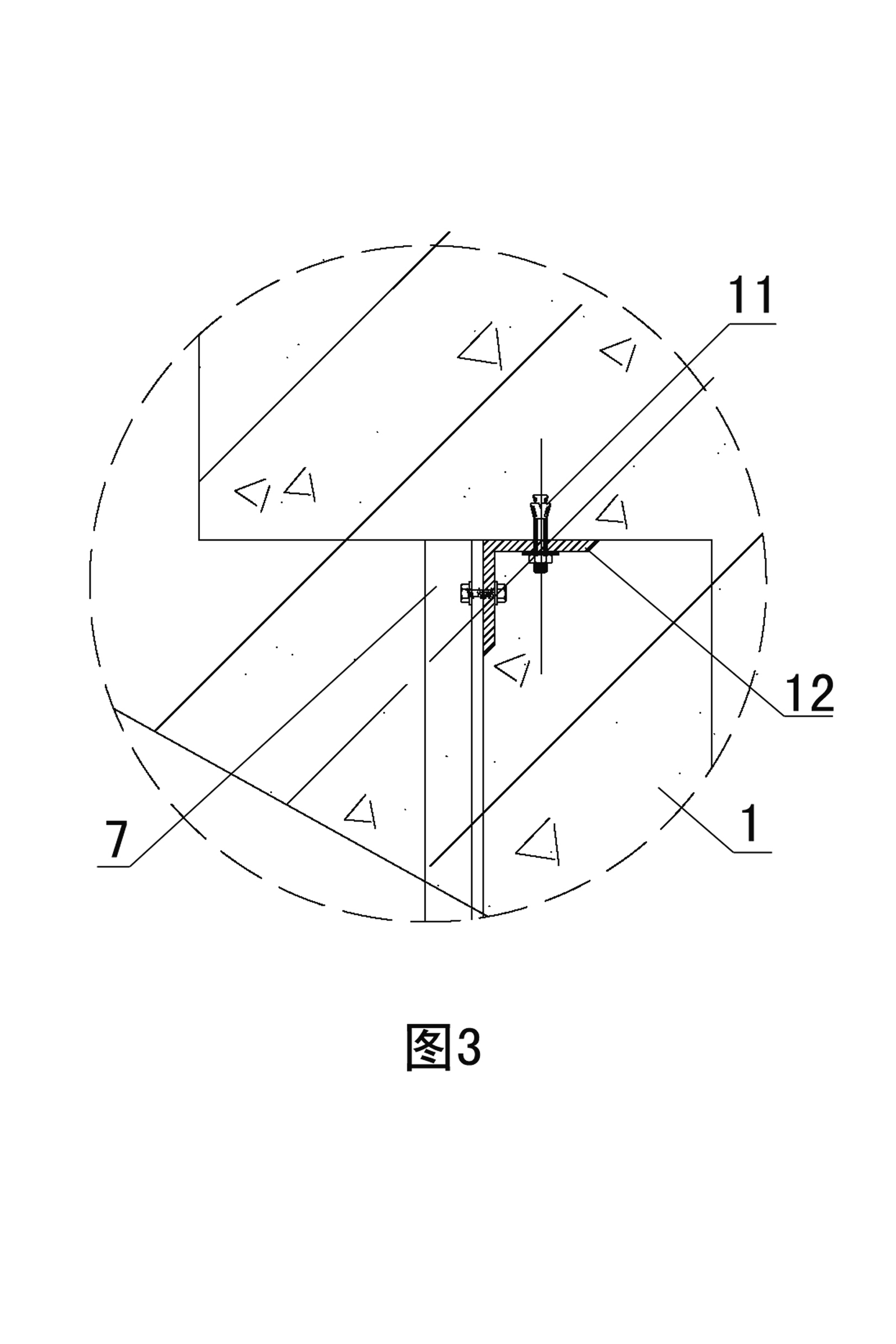

[0038] The audience rest hall on the second floor of a gymnasium adopts the aluminum square ceiling. The entire ceiling is arranged in a fan shape. The chord length of the circle formed by the fan shape is more than 70 meters. It rises gradually along the auditorium, and the highest point exceeds 10 meters. Due to the high ceiling height, it is inconvenient to operate during construction, and it is difficult to control the overall shape of the ceiling. The aluminum square ceiling area is relatively large, nearly 600m2 2 , the shape of the entire ceiling is peculiar, the ceiling is arranged in a fan shape on the plane, the long axis of the ceiling is arc-shaped, and the short axis is gradually raised along the concrete roof of the audience. , the connectors cannot be guaranteed to match completely. Therefore, during construction, the hanging method of the aluminum square ceiling, the selection of accessories and connectors are a key consideration during construction.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com