Composite combustion regulator, flame-retardant additive, cigarette paper prepared from flame-retardant additive, and fine cigarette

A technology of combustion regulator and flame retardant additive, which is applied in the direction of fire retardant addition, non-fiber pulp addition, paper, etc. It can solve the problems of irritation and high turning rate of combustion cones, and achieve less irritation, simple production process and equipment requirements , easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

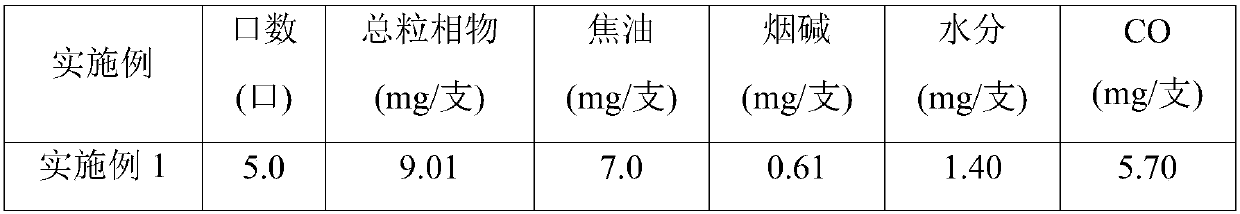

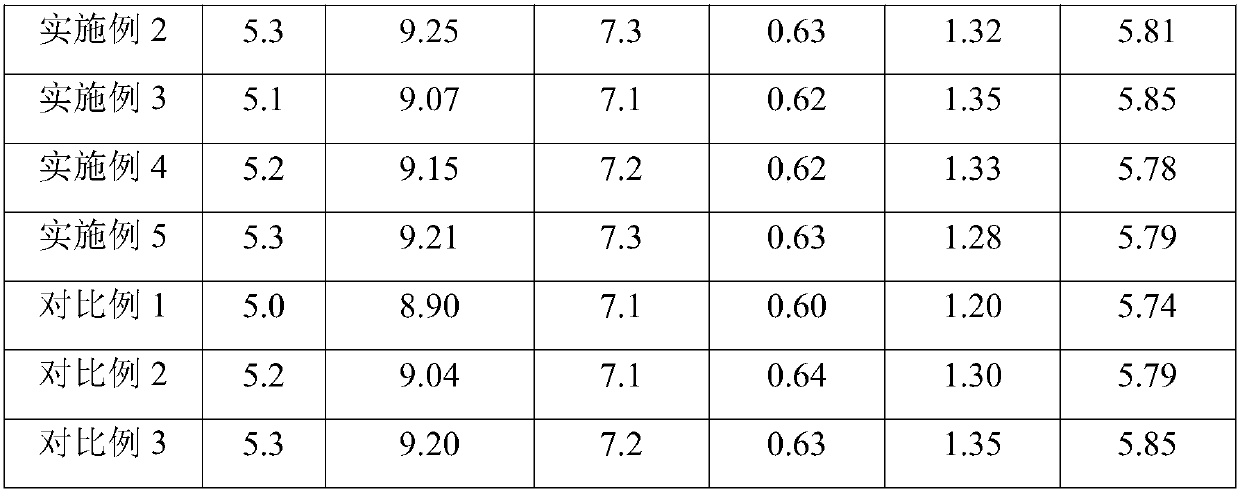

Embodiment 1

[0048] Take 50 kg of coniferous wood pulp, 400 kg of hardwood pulp, 150 kg of hemp pulp, add 180 kg of filler calcium carbonate, 20 kg of monobutyltin trilaurate, 15 kg of calcium stearate, and 35 kg of aluminum dihydrogen phosphate through beating. After mixing, it is molded on the Internet, squeezed and dried, and the prepared combustion accelerant is added to the surface sizing place. The specific addition method is: add 100 parts of water, 3 parts of potassium citrate, 2 parts of sodium citrate and 1 part of sodium phosphate, stirred for 20 minutes to mix evenly, and applied to the reverse side of the cigarette paper through the surface sizing device inside the machine. Control the characteristics of cigarette paper on the paper machine: quantitative 27 g / m 2 , Air permeability 50 Coresta.

Embodiment 2

[0050] Take 50 kg of coniferous wood pulp, 400 kg of hardwood pulp, and 150 kg of hemp pulp, add 150 kg of filler calcium carbonate, 30 kg of monobutyltin trilaurate, 20 kg of calcium stearate, and 50 kg of aluminum dihydrogen phosphate through beating. After mixing, it is molded on the Internet, squeezed and dried, and the prepared combustion accelerant is added to the surface sizing place. The specific addition method is: add 100 parts of water, 3 parts of potassium citrate, 2 parts of sodium citrate and 1 part of sodium phosphate, stirred for 20 minutes to mix evenly, and applied to the reverse side of the cigarette paper through the surface sizing device inside the machine. Control the characteristics of cigarette paper on the paper machine: quantitative 27 g / m 2 , Air permeability 50 Coresta.

Embodiment 3

[0052] Take 50 kg of coniferous wood pulp, 400 kg of hardwood pulp, 150 kg of hemp pulp, add 180 kg of filler calcium carbonate, 20 kg of monobutyltin trilaurate, 15 kg of calcium stearate, and 35 kg of aluminum dihydrogen phosphate through beating. After mixing, it is molded on the Internet, squeezed and dried, and the prepared combustion accelerant is added to the surface sizing place. The specific addition method is: add 100 parts of water, 1 part of potassium citrate, 3 parts of sodium citrate and 2 parts of sodium phosphate, stirred for 20 minutes to mix evenly, and applied to the reverse side of the cigarette paper through the surface sizing device inside the machine. Control the characteristics of cigarette paper on the paper machine: quantitative 27 g / m 2 , Air permeability 50 Coresta.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com