Soft water cyclic heating/cooling system corrosion inhibitor and preparation method thereof

A cooling system, water circulation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve problems such as high cost, hindering wide-scale application, and inability to solve carbon steel corrosion problems. , to reduce the processing cost, reduce the risk of eutrophication, and improve the reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

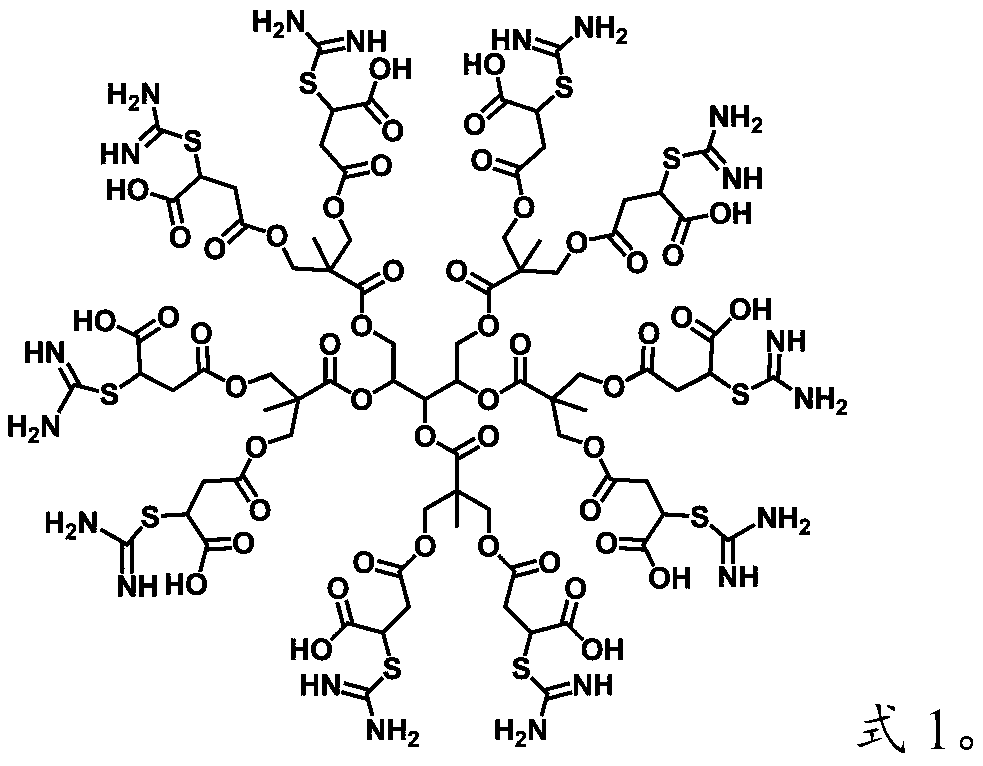

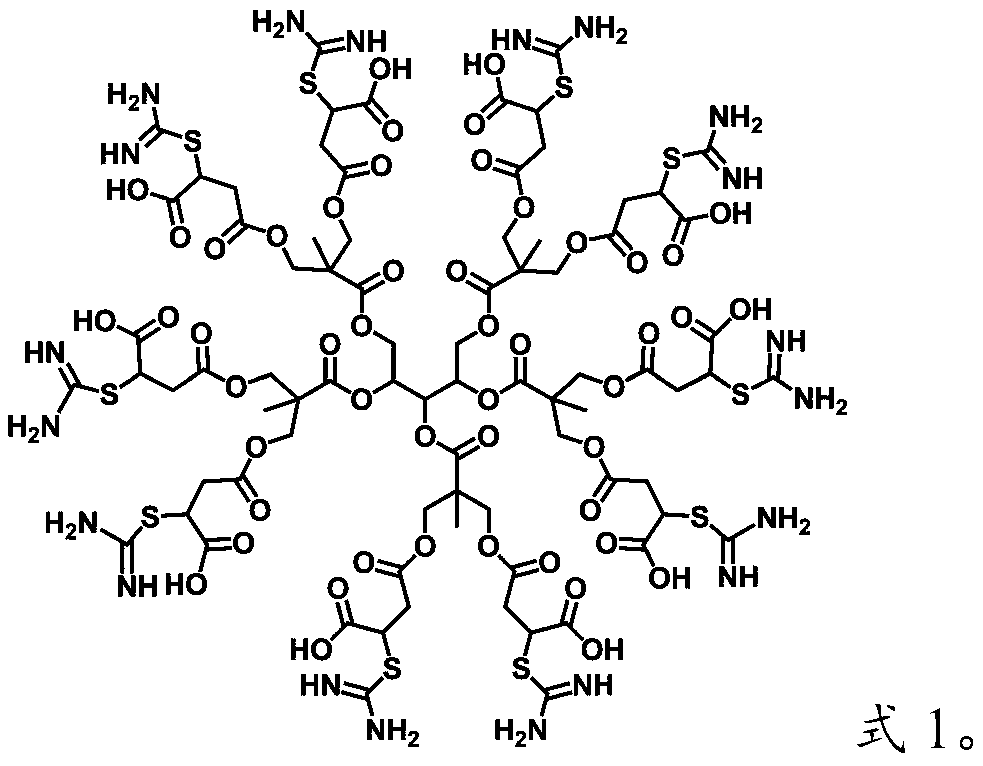

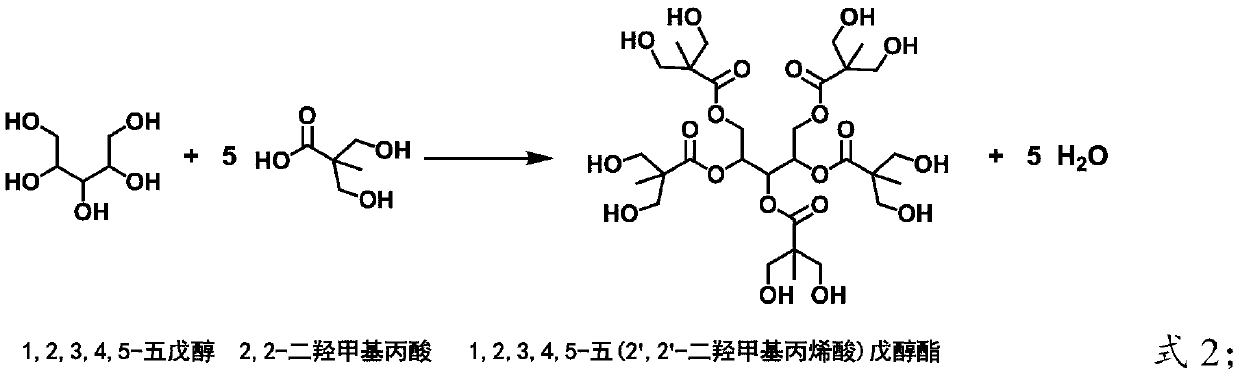

[0033] Preparation of hyperbranched macromolecules with isothiourea group and carboxyl functionalized pentapentanol core:

[0034] At room temperature, 15.20g (0.10mol) xylitol (1,2,3,4,5-pentapentyl alcohol), 67.00g (0.50mol) 2,2-dimethylolpropionic acid, 1.00g Add p-toluenesulfonic acid into four-necked round-bottomed flasks equipped with stirring, reflux condenser and thermometer respectively, mix and stir evenly. Nitrogen was blown, and the temperature was raised to 145°C. After reacting for 3 hours, and then reacting for 4 hours under reduced pressure, a viscous substance was obtained. Then cool down to 80°C, add 100g of glacial acetic acid to dissolve, then add 196.00g of maleic anhydride in acetic acid solution (maleic anhydride 1.00mol, mass concentration 50%), and react for 4h. Then the temperature was lowered to 55° C., and 152.00 g of thiourea in acetic acid (1.00 mol of thiourea, 50% mass concentration) was added to react for 5 hours. After cooling to room temper...

Embodiment 2

[0040] Preparation of hyperbranched macromolecules with pentapentanol core functionalized with isothiourea groups and carboxyl groups

[0041] At room temperature, 15.20g (0.10mol) DL-arabitol (1,2,3,4,5-pentapentyl alcohol), 67.00g (0.50mol) 2,2-dimethylolpropionic acid, Add 1.00 g of p-toluenesulfonic acid to a four-neck round bottom flask equipped with stirring, reflux condenser and thermometer, and mix and stir evenly. Nitrogen was blown, the temperature was raised to 140° C., and after reacting for 5 hours, the reaction was continued for 5 hours under reduced pressure to obtain a viscous substance. Then cool down to 80°C, add 100g of glacial acetic acid to dissolve, then add 197.96g (1.01mol, 50%) maleic anhydride in acetic acid solution, and react for 4h. Then the temperature was lowered to 55° C., and 155.04 g (1.02 mol, 50%) of thiourea in acetic acid was added to react for 5 h. After cooling to room temperature, a white substance was precipitated, filtered with suct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com