A kind of highly concentrated universal color paste and its preparation method and application

A high-concentration and color paste technology, which is applied in the direction of pigment paste, coating, epoxy resin coating, etc., can solve the problem of deep color of polyester resin, poor stability of ester bonds, and influence on paint film resistance, color retention and gloss retention and other problems, to achieve the effects of no floating color and flowering, excellent color and gloss retention, alkali and water resistance, and reducing the possibility of re-flocculation or aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

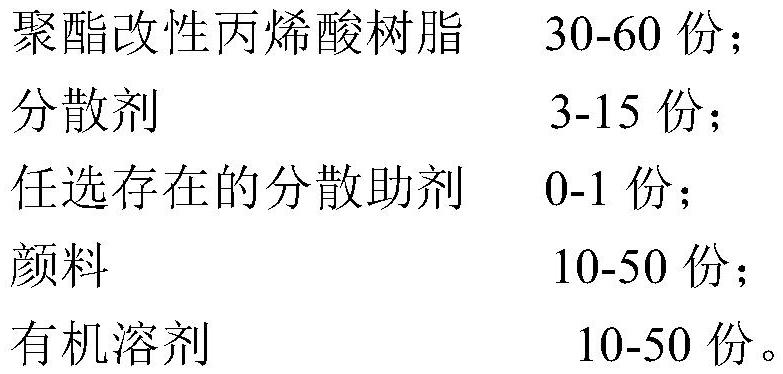

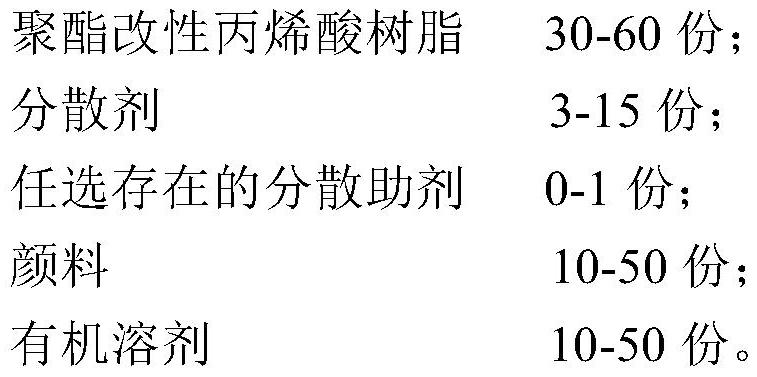

Method used

Image

Examples

preparation example Construction

[0040] In a preferred example, the preparation method of the polyester modified acrylic resin comprises the following steps:

[0041] Mix lauric acid, isononanoic acid, isooctanoic acid, NPG, TMP, terephthalic anhydride, hexahydrophthalic anhydride, tetrahydrophthalic anhydride and butenedioic anhydride and heat up to 120°C, dehydrate and heat up to 225°C within 4 hours. ℃ for 0.5 hours, when the acid value is less than 30mgKOH / g, add xylene to reflux, when the acid value is less than 6.5-10.5mgKOH / g and the viscosity is Z1-Z3, the polyester intermediate is obtained;

[0042] The polyester intermediate and solvent are heated to 150-160° C. under nitrogen protection, a mixture of acrylate monomer and 90wt% initiator is added dropwise within 3 hours, and the remaining initiator is added after holding for 1 hour. , heat preservation for 3 hours, and dilute to 70% solid content to obtain the polyester modified acrylic resin.

[0043]The above polyester modified acrylic resin stru...

Embodiment 1

[0066] The highly concentrated general environment-friendly color paste raw materials of this embodiment include: 31kg of polyester modified acrylic resin A with a mass percentage of 70%, 9.5kg of propylene glycol methyl ether acetate, 5kg of S-100 solvent, 48kg of iron yellow, polyurethane Dispersant 6.5kg.

[0067] Its preparation method is: (1) add 31kg of polyester modified acrylic resin A, 6.5kg of polyurethane-based dispersant, 9.025kg of propylene glycol methyl ether acetate, and 4.75kg of S-100 solvent into a container of suitable size, stir (400 -600rpm) for 10-15 minutes; (2) while stirring, add 48kg of PY42 iron yellow pigment, after adding the pigment, stir (400-600rpm) for 10-15 minutes; (3) while stirring, add residual solvent propylene glycol methyl along the container wall Ether acetate and S-100 solvent, continue to stir for 30 minutes until uniform; (4) start grinding and dispersing on the designated sand mill until the fineness meets the requirements;

[00...

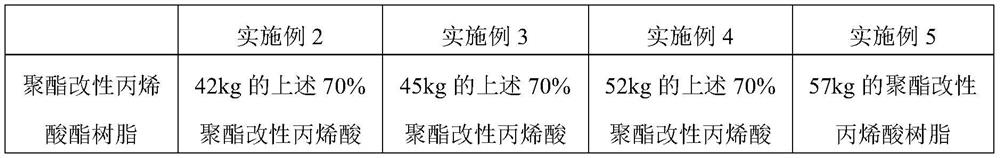

Embodiment 2-5

[0070] The components of the high-concentration universal environmentally friendly colorants of each embodiment are shown in Table 1, the preparation method of each embodiment is basically the same as that of Example 1, and the technical indicators of the obtained coatings are shown in Table 2.

[0071] The formula composition of table 1 embodiment 2-5 environmental protection color paste

[0072]

[0073]

[0074] Table 2 Properties of the colorants obtained in Examples 1-5

[0075]

[0076] The above-mentioned high-concentration universal colorants were used to replace the original low-concentration colorants of several product systems to formulate color paints, and the key performance changes before and after the replacement were investigated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com