Highly conductive, stretchable and compressible, repairable zwitterionic gel polymer electrolyte and its preparation and application

A gel polymer, stretch-compression technology, applied in the direction of hybrid capacitor electrolytes, etc., can solve the problems of application limitations, inability to have both conductivity, stretch-compression, adhesive repairability, etc. Universality, the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1 Experimental part

[0041] 1.1 Raw materials and reagents

[0042] Table 3-1 Main raw materials and reagents

[0043]

[0044] 1.2 Experimental equipment

[0045] Table 3-2 Main experimental equipment

[0046]

[0047]

[0048] 1.3 Experimental synthesis method

[0049] 1.3.1 Preparation of P(HEMA-SBMA) hydrogel electrolyte

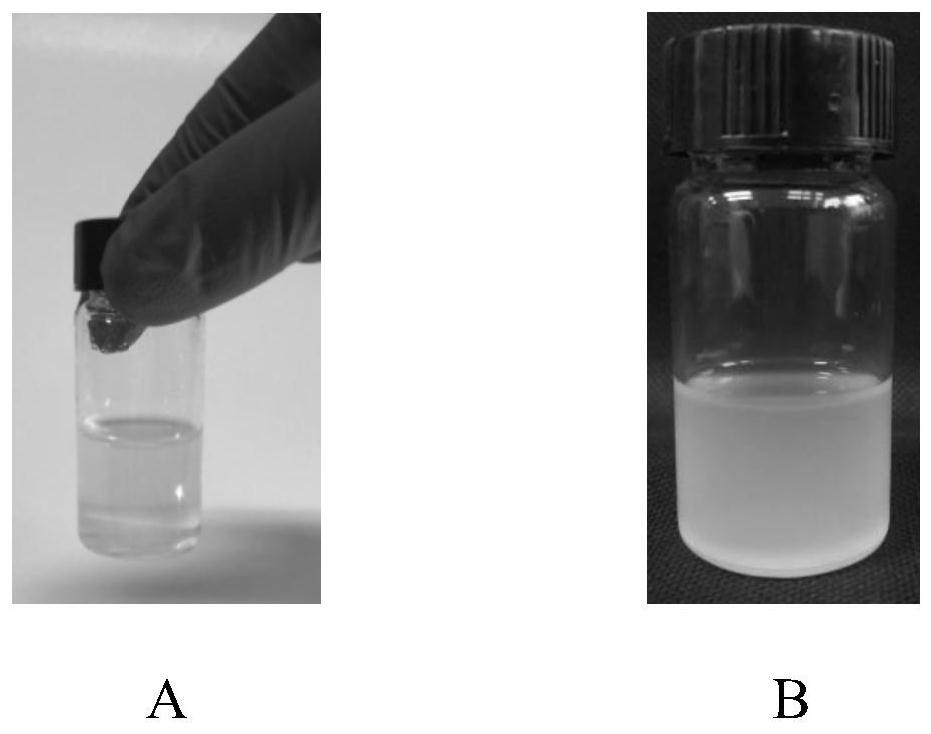

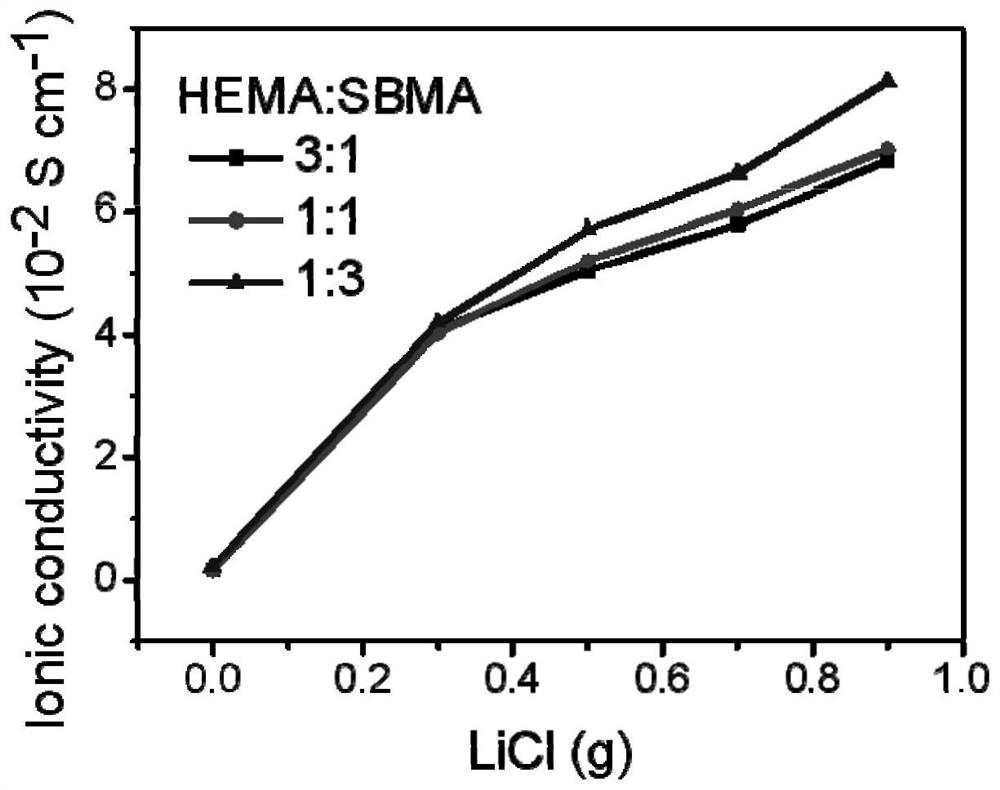

[0050] The P(HEMA-SBMA) electrolyte was prepared by radical polymerization of SBMA, HEMA and LiCl. Add 2 g of SBMA, HEMA, and distilled water (6 mL) into 20-ml glass bottles, respectively, and the molar ratios of the two monomers are 3:1, 1:1, and 1:3, respectively. Then LiCl with different masses was added into the mixed solution. Then the above solution was stirred in an ice bath for 1.5 hours, and then 0.02 g of AIBA was added as an initiator. Polymerize at 37°C for 24h to obtain P(HEMA-SBMA) electrolyte.

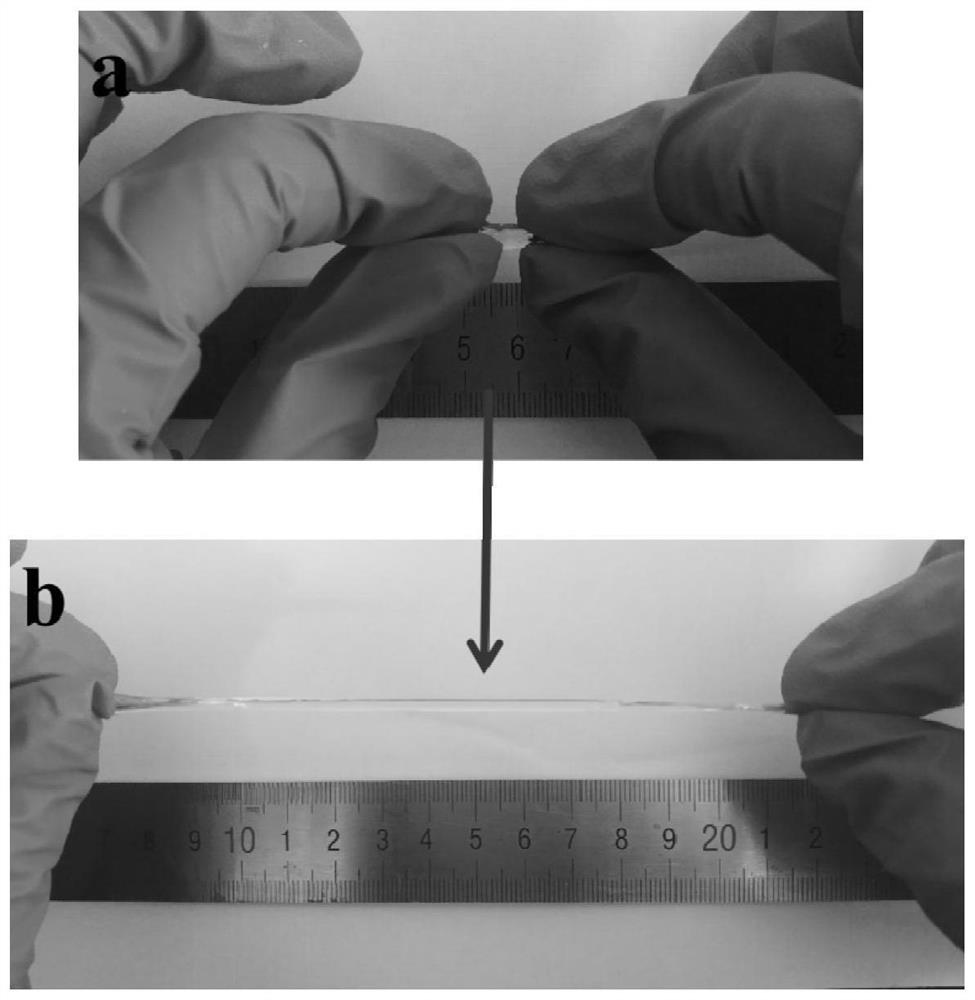

[0051] 1.3.2 Compression performance test of P(HEMA-SBMA) electrolyte

[0052] The compression cycle test is performed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com