A kind of antiflame agent mixed explosive and preparation method thereof

A technology for mixing explosives and flame suppressants, which is used in explosives processing equipment, explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problem that the detonation energy of mixed explosives fluctuates greatly and limits wide-scale application , difficult to mix the main explosives, etc., to achieve the effect of good bonding effect, good compression performance, and uniform product particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

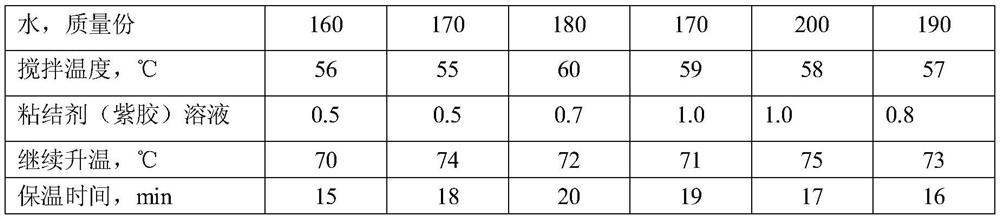

[0014] The technical solution of the present invention will be described in detail below through six specific examples. In each embodiment, the mixed explosives are prepared by the traditional solution water suspension distillation method.

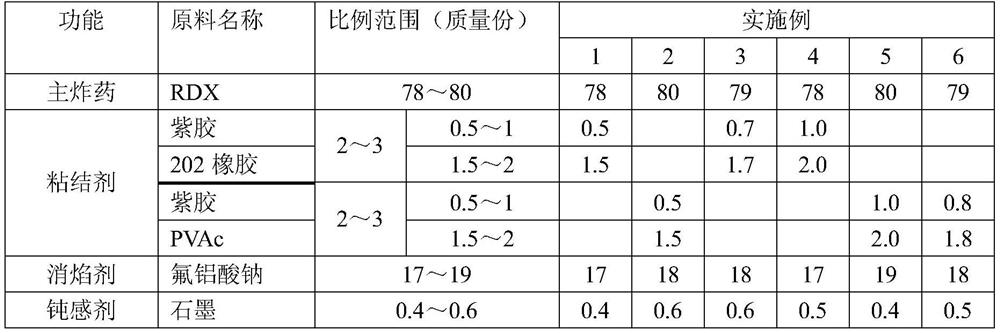

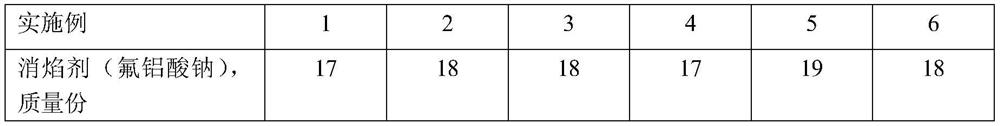

[0015] Each embodiment relates to a flame suppressant mixed explosive. The flame suppressant mixed explosive is composed of main explosive RDX, binder, flame suppressant and desensitizing agent, and the composition of each raw material is shown in the following table:

[0016]

[0017] In described each embodiment, the concrete process of preparing described flame suppressant mixed explosive is:

[0018] Step 1: Configure the binder solution, add 0.5-1 mass parts of shellac and 5-16 mass parts of ethanol in 1# dissolving machine, heat and stir to dissolve the shellac, and make a uniform shellac solution; dissolve in 2# Add 1.5 to 2 parts by mass of 202 rubber or PVAc, and 12 to 24 parts by mass of ethyl acetate to completely dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com