Method for preparing geopolymer finished product by using typical rare earth tailings in western Sichuan

A technology of rare earth tailings and geopolymers, which is applied in solid waste management, sustainable waste treatment, cement production, etc., can solve the problems of few researches on solid sealing of pollution sources, and achieve the effect of reducing hidden dangers of land disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention uses the chemical composition of bastnaesic rare earth tailings in western Sichuan to include in terms of oxides: Al 2 o 3 7.459%, SiO 2 24.253%, K 2 O 2.595%, CaO 20.282%, SrO 10.481%, BaO 3.996%, F 6.633%, Fe 2 o 3 3.172% and SO 3 7.057%, mass percentage.

[0037] The chemical composition of metakaolin in terms of oxides includes: Al 2 o 3 41.908%, SiO 2 52.195%, K 2 O1.967%, Fe 2 o 3 0.989%, TiO 2 0.209% and MgO 0.239%, mass percentage, the silica fume used is industrial grade product amorphous SiO 2 , SiO 2 Content>98%, mass percentage, NaOH is analytical pure or industrial pure chemical reagent, heavy metal source lead salt Pb(NO 3 ) 2 For analytically pure chemical reagents.

[0038] 25g of bastnaesite rare earth tailings in western Sichuan, 100g of metakaolin, 44g of silica fume, 34g of NaOH, 138 mL of water, heavy metal source (lead salt Pb(NO 3 ) 2 ) 0.406g, L / S is 1.0. The following preparation method was adopted...

Embodiment 2

[0046] 25g of bastnaesite rare earth tailings in western Sichuan, 100g of metakaolin, 44g of silica fume, 34g of NaOH, 113 mL of water, heavy metal source (lead salt Pb(NO 3 ) 2 ) 0.812g, L / S is 0.9. Using the preparation method, a rare earth tailings-metakaolin base polymer sample was obtained, and its 7d compressive strength value was 15.69 MPa. The leaching toxicity evaluation was carried out by using the leaching toxicity leaching method (TCLP). 2+ The concentration is 1.05 mg / L, which is lower than the limit value for heavy metal ions in the leachate in the national standard GB5085.3-2007 "Identification Standard for Hazardous Wastes - Identification of Leaching Toxicity": total Pb<5 mg / L.

[0047] Others are the same as in Example 1.

Embodiment 3

[0049] Using 25g of bastnaesite rare earth tailings in western Sichuan, 100g of metakaolin, 44g of silica fume, 34g of NaOH, 88 mL of water, heavy metal source (lead salt Pb(NO 3 ) 2 ) 4.06g, L / S is 0.7. Using the preparation method, a rare earth tailings-metakaolin base polymer sample was obtained, and its 7d compressive strength value was 36.1 MPa. The leaching toxicity evaluation was carried out by using the leaching toxicity leaching method (TCLP). 2+ The concentration is 0.261 mg / L, which is far lower than the limit value of heavy metal ions in the leachate in the national standard GB5085.3-2007 "Identification Standard for Hazardous Wastes - Identification of Leaching Toxicity": total Pb<5 mg / L.

[0050] Others are the same as in Example 1.

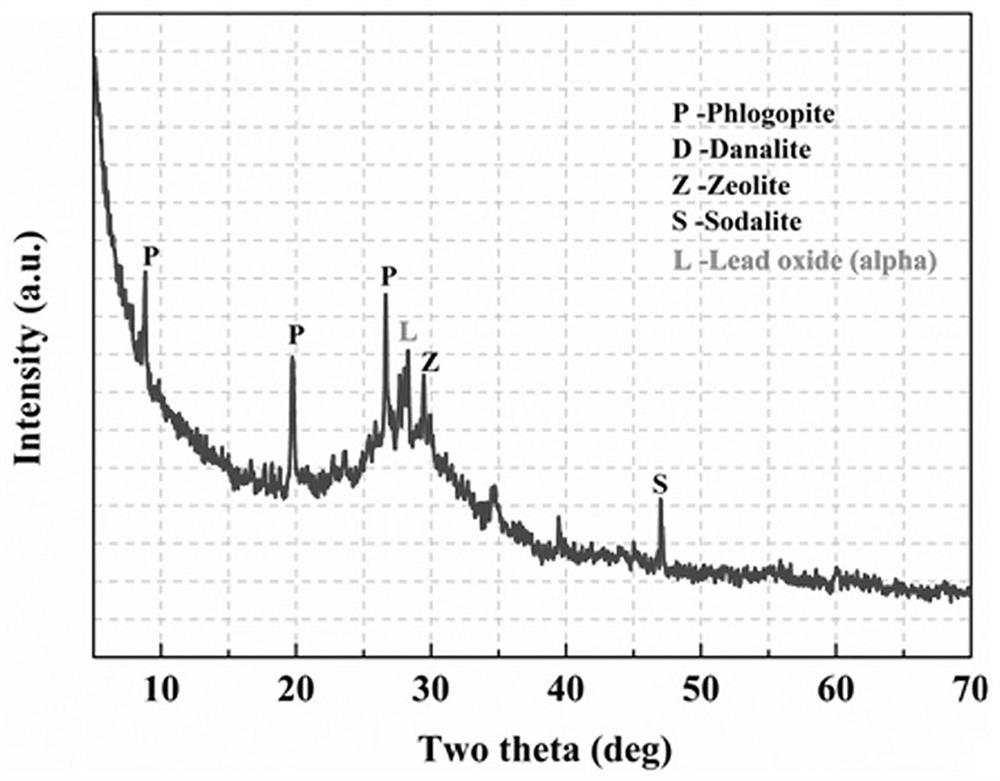

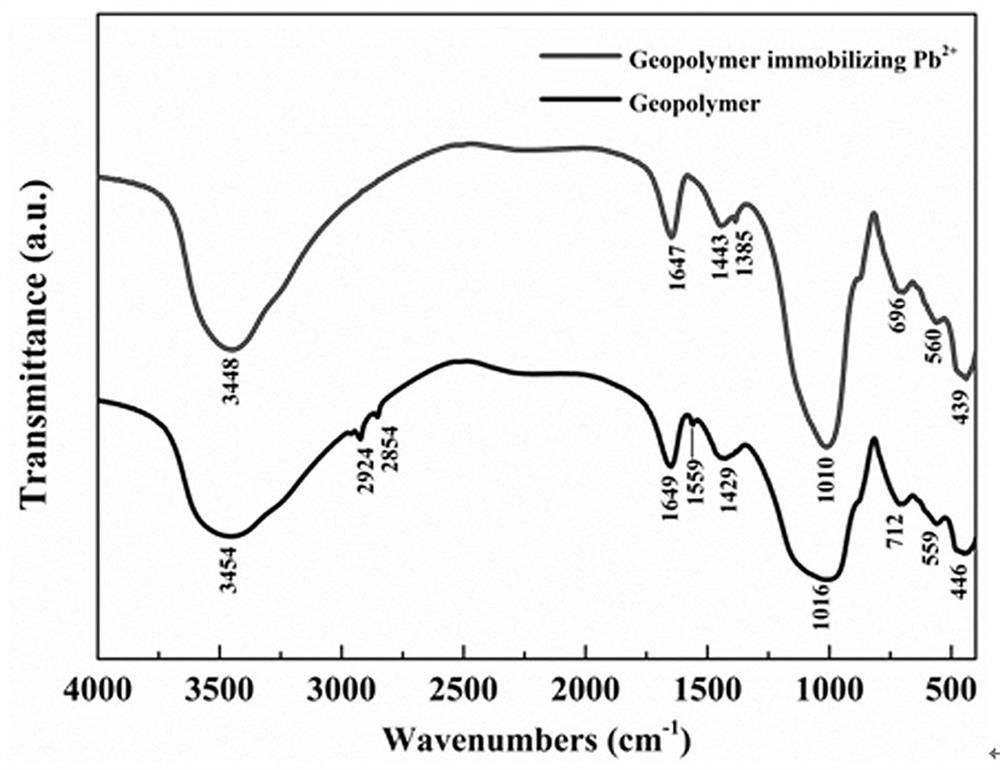

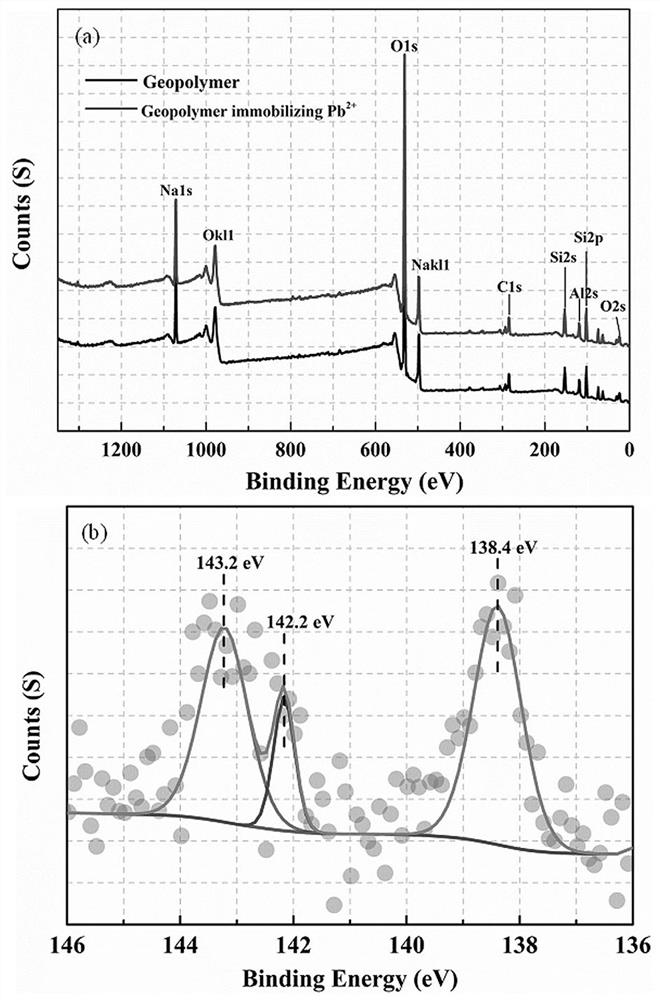

[0051] Carry out structure and action principle analysis to embodiment 3 geopolymer samples as follows:

[0052] By carrying out mechanism analysis to the rare earth tailings-metakaolin base polymer of embodiment 3 solidifying h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com