A body installation structure based on the front floor reinforcement beam structure of pure electric vehicles

A pure electric vehicle and installation structure technology, applied in the superstructure, superstructure sub-assemblies, vehicle components and other directions, can solve the problems of reduced side impact performance, insufficient strength, compressed lateral load transfer space, etc., to improve safety, The effect of optimizing the transfer path and improving the safety performance of side impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

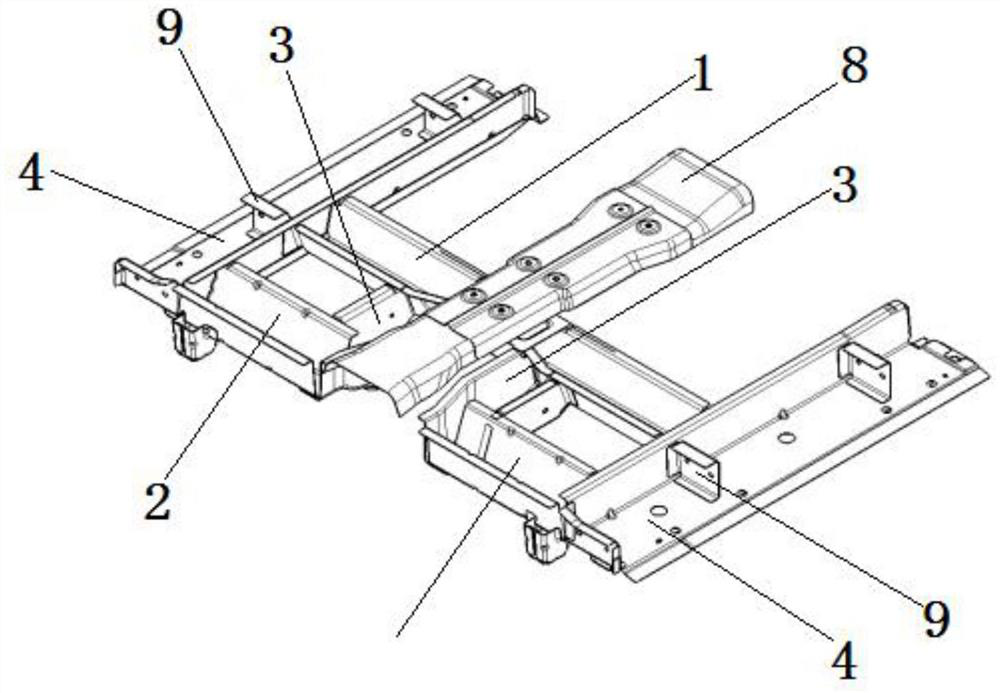

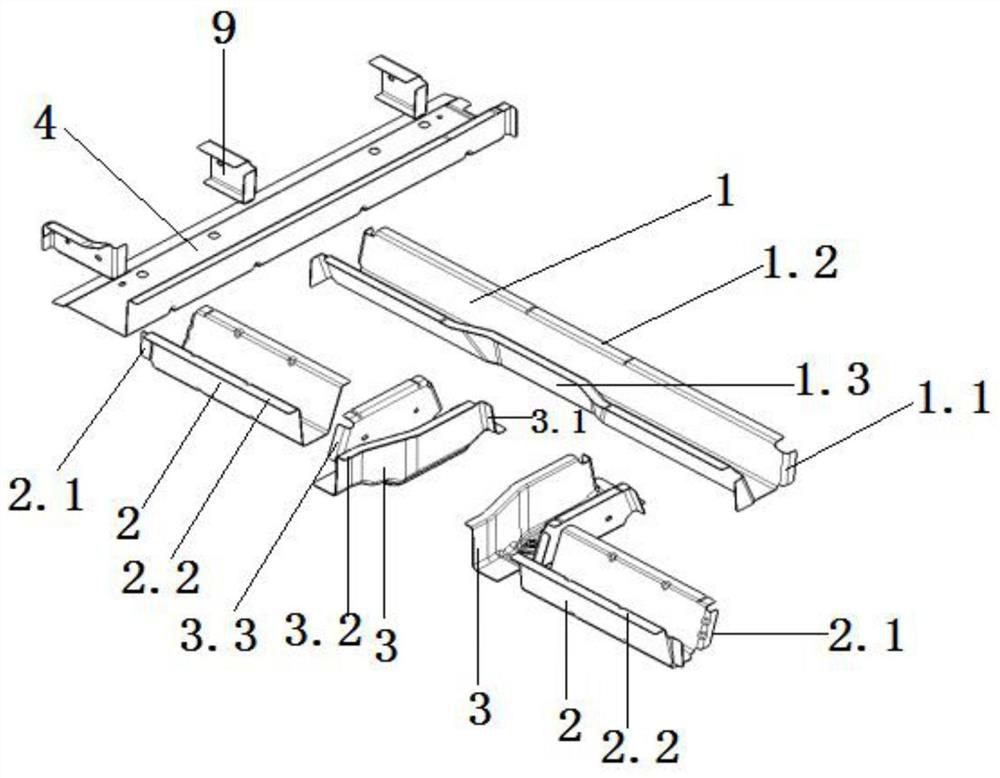

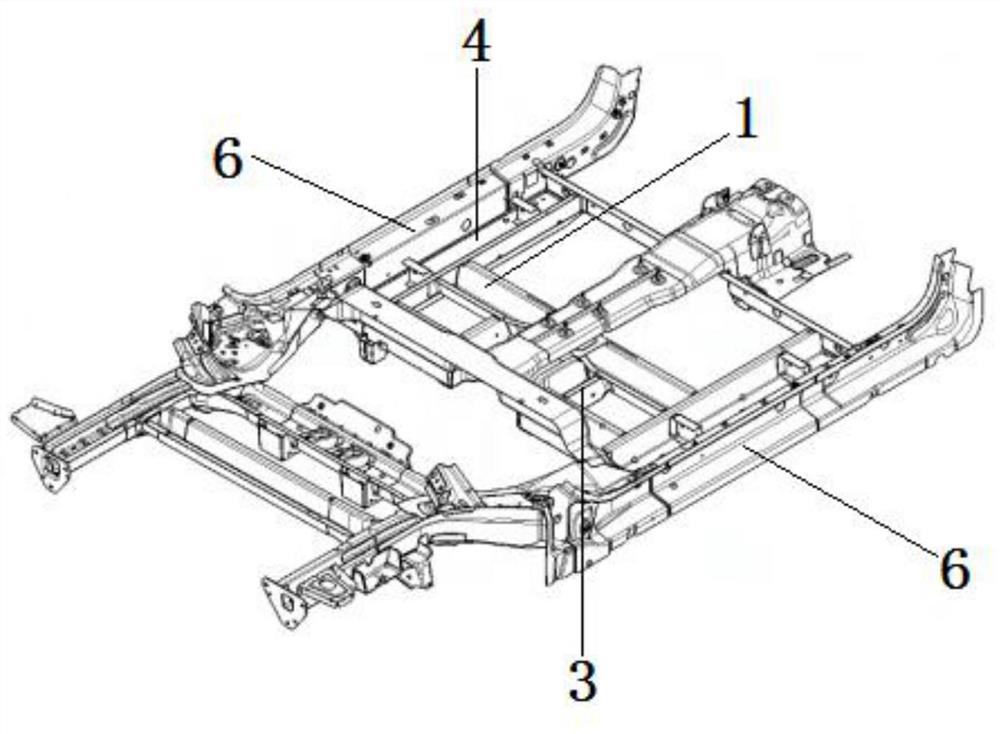

[0026] The front floor reinforced beam structure based on pure electric vehicles as shown in Figure 1-9 includes the first reinforced beam 1 and the second reinforced beam located in front of the first reinforced beam 1 and arranged parallel and symmetrically on the left and right sides of the first reinforced beam 1 The beam 2, the second reinforced beam 2 and the first reinforced beam 1 are fixed by the reinforced longitudinal beam 3 perpendicular to the first reinforced beam 1 and the second reinforced beam 2; the left and right sides of the first reinforced beam 1 and the second reinforced beam The side of the beam 2 that is not fixed to the reinforcement beam 3 is connected with a beam overlap structure that can be fixed to the battery box installation beam 4, the top of the first reinforcement beam 1, the top of the reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com