Super Torque Double Helix Double Transcendence Integrated Intelligent Adaptive Electric Drive Rear Drive System

A double helix, integrated technology, applied in the direction of electric power unit, power unit, control device, etc., can solve the problems of limited load capacity, influence mechanism layout, high manufacturing cost, etc., to improve the load bearing capacity, increase High-efficiency operation range, suitable for high-torque power transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

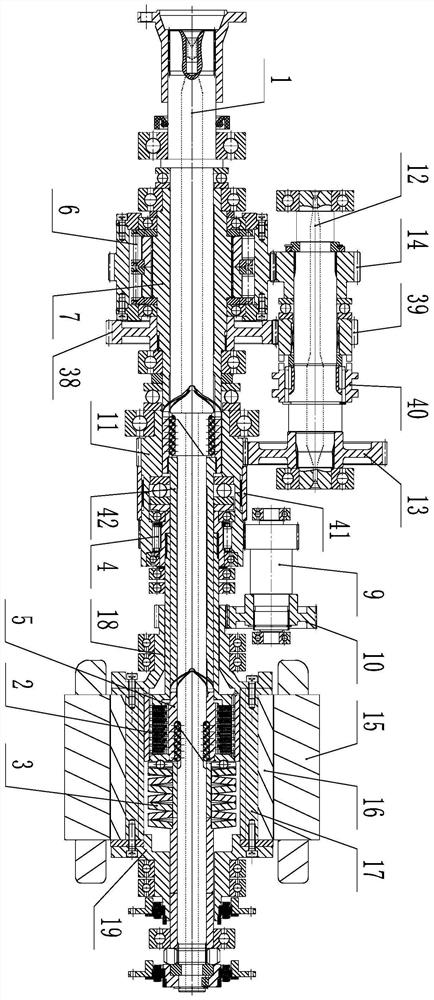

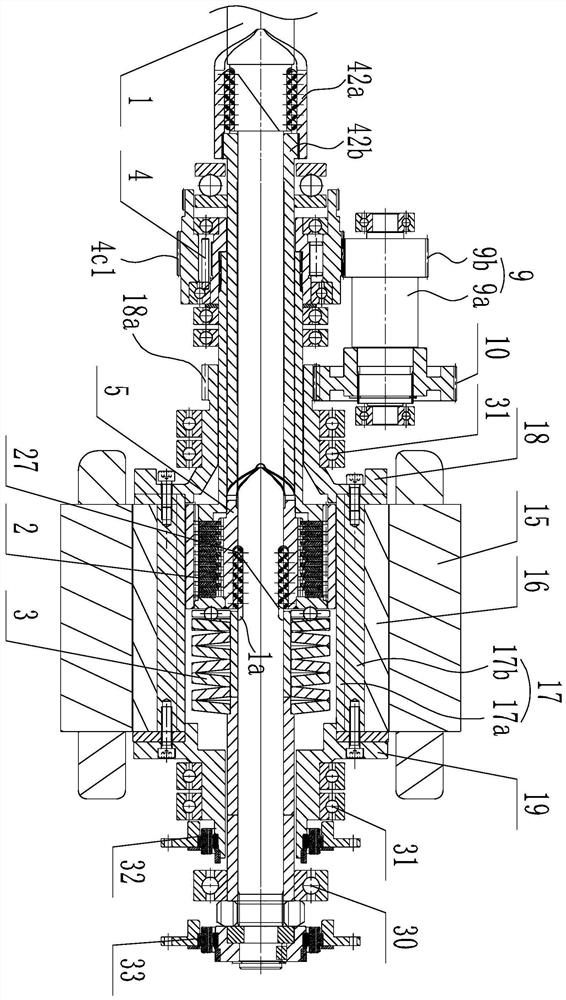

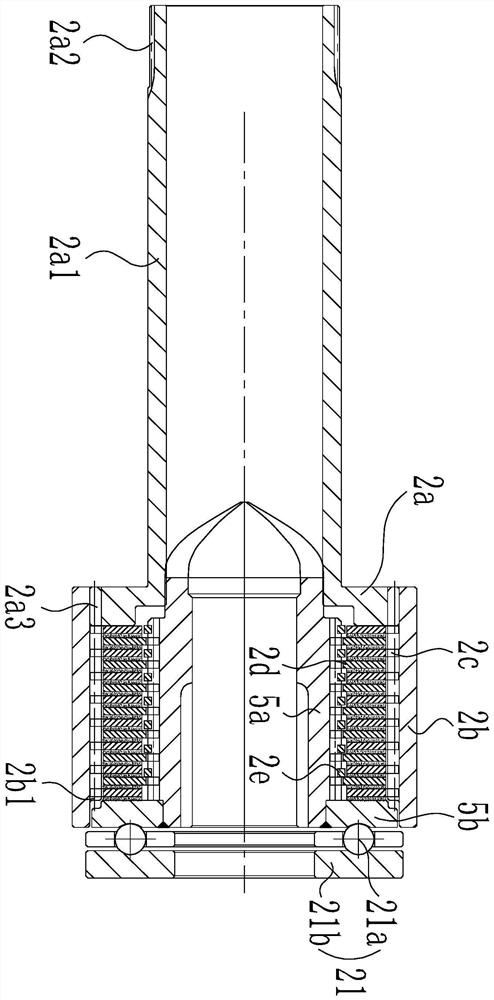

[0040] Such as figure 1 , figure 2 and Figure 8 As shown, a super-torque double-helix double-override integrated intelligent adaptive electric drive rear drive system mainly includes a motor, a high-speed gear transmission mechanism, a low-speed gear transmission mechanism, and a main shaft 1 for outputting power.

[0041] The motor includes a stator 15, a rotor 16 and a motor shaft assembly driven by the rotor 16. The motor shaft assembly includes a motor hollow shaft 17 and power transmission flanges 18 and outer mounting flanges 19 respectively arranged at both ends of the motor hollow shaft 17. The motor hollow shaft 17 is fixed on the inner side of the rotor 16 through the power transmission flange 18 and the outer mounting flange 19, that is, the rotor 16 drives the motor hollow shaft 17 to rotate synchronously through the power transmission flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com