A plastic masterbatch processing and preparation system

A plastic masterbatch and preparation system technology, which is applied in the direction of coating, etc., can solve the problems that water vapor cannot be effectively recovered, the quality of plastic masterbatch products is reduced, the structure of additives and fillers is unstable, and the structure is compact and drying is reduced time, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

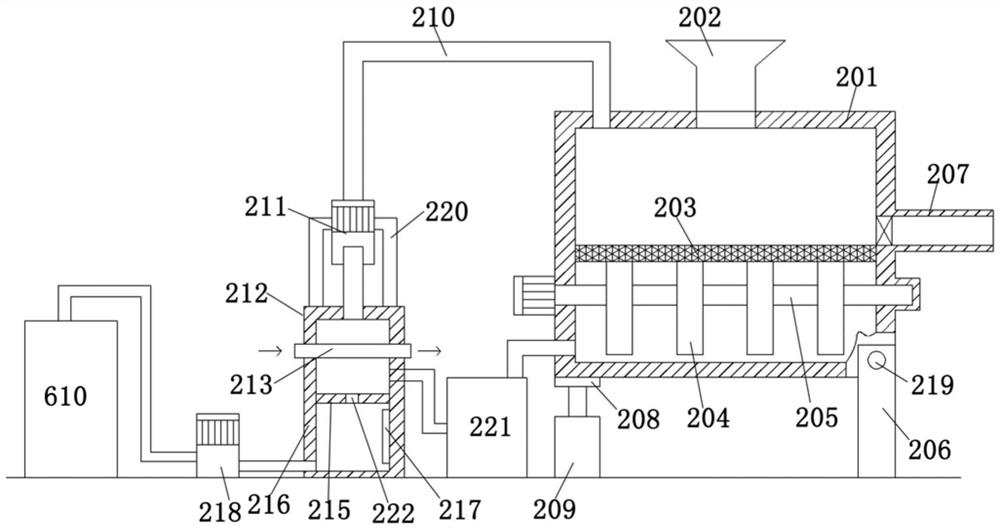

[0048] Example: such as Figure 1-4 A plastic masterbatch processing and preparation system shown includes molding equipment and drying equipment. After the plastic masterbatch is processed by the molding equipment, it is transported to the drying equipment by a conveyor belt (not shown in the figure) or manually. The drying equipment Including a housing 201, the upper end of the housing 201 is connected to the hopper 202, the inner wall of the housing 201 is fixed with a parabolic cloth 203, and the bottom of the parabolic cloth 203 is pressed against a plurality of eccentric wheels 204, and the eccentric wheels 204 are fixed to the motor-driven On the rotating shaft 205. The right end of the housing 201 is hinged on the hinge plates 206 on both sides. The right side of the housing 201 is connected with a discharge pipe 207. The lower end of the left side of the housing 201 is pressed against the lifting plate 208. The lifting plate 208 and a plurality of hydraulic pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com