Isostatic double-circulation-pressure automatic grouting forming production line for ceramic throwing

A technology of automatic grouting molding and circulating pressure, applied in the field of ceramic processing, can solve the problems of insufficient quality, deviation of the plastic shape of the drawn ceramic, weak fragile surface, etc., and achieve the effect of rapid and thorough molding and smooth and synchronous effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

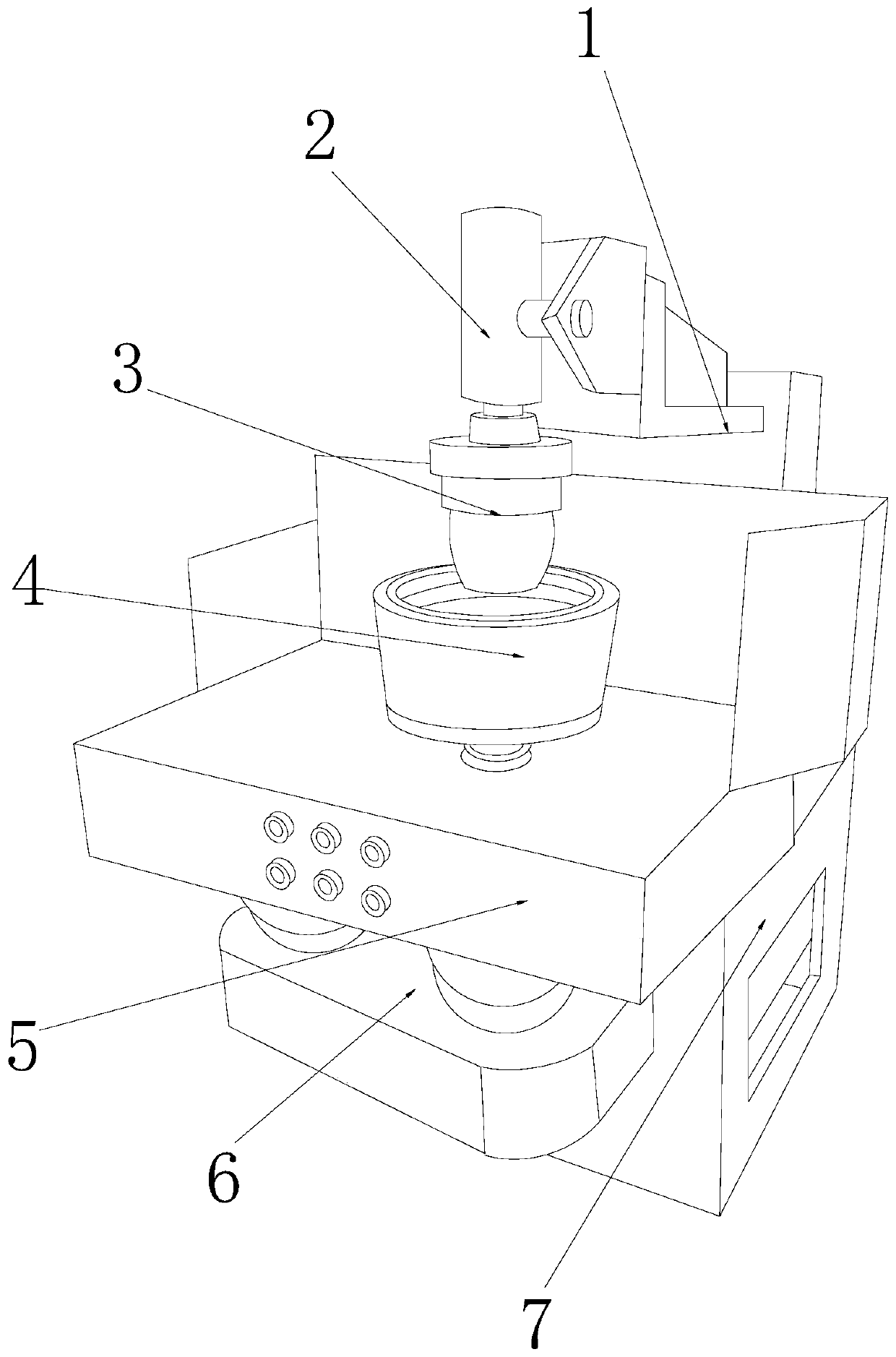

[0033] see Figure 1-Figure 7, the present invention provides an isostatic double-loop flow pressure automatic grouting molding production line for ceramic casting. Workbench 5, double motor socket 6, power distribution base 7, the double-ring drawing cap body 3 is nested under the bottom of the stepping motor 2 and the axes are collinear, and the stepping motor 2 is nested in the back seat The front side of the board frame 1, the rear seat board frame 1 is inserted and embedded in the rear side of the workbench 5 and is perpendicular to each other, the loading basin 4 is mechanically connected to the workbench 5, and the double motor socket 6 is connected to the matching The electric base 7 is inserted and embedded under the bottom of the workbench 5, the double motor socket 6 is electrically connected with the power distribution base 7 and is on the same level, and the double-ring drawing cap body 3 is provided with a double-wheel hanger 3A, top turntable block 3B, pneumati...

Embodiment 2

[0040] see Figure 1-Figure 7 , the present invention provides a kind of automatic grouting molding production line of isostatic double-loop pressure of ceramic casting, other aspects are the same as embodiment 1, the difference is:

[0041] see image 3 The bottom support sliding rubber seat 3H is composed of a bottom support sliding plate 3H1, a bottom support rubber groove 3H2, and a rubber seat valve core 3H3. The bottom support sliding plate 3H1 is nested under the bottom of the bottom support rubber groove 3H2 and the axes are collinear , the rubber seat valve core 3H3 is installed inside the bottom support rubber groove 3H2, and the chassis surface of the bottom support rubber groove 3H2 is pressed and covered by the bottom support rubber groove 3H2 through the bottom pad slide plate 3H1. The plastic surface is pressed against the flowing mud to form the inner plastic positioning effect of the ceramic.

[0042] see Figure 7 , the rubber-seat valve core 3H3 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com