Automobile accessory welding mechanical arm with clamp convenient to replace

A technology for welding manipulators and auto parts, applied to vehicle parts, welding equipment, auxiliary welding equipment, etc., can solve problems such as inability to adjust, physical damage of staff, rusted bolts, etc., to ensure normal use, stability, The effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

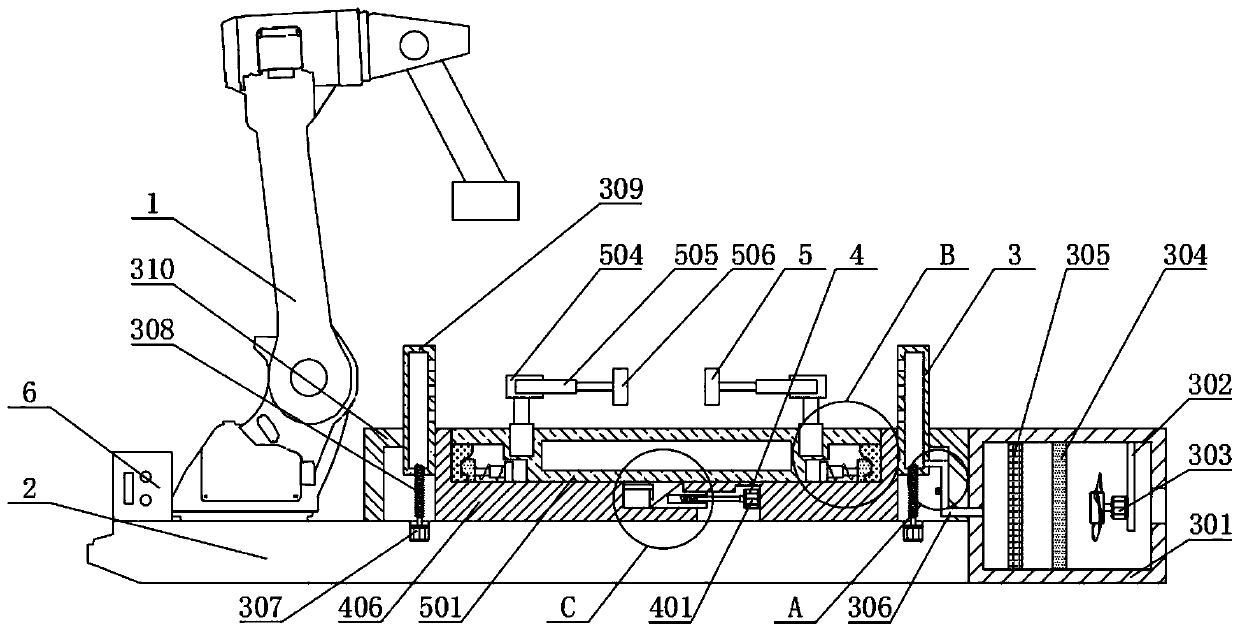

[0026] see Figure 1-6 , the present invention provides a technical solution:

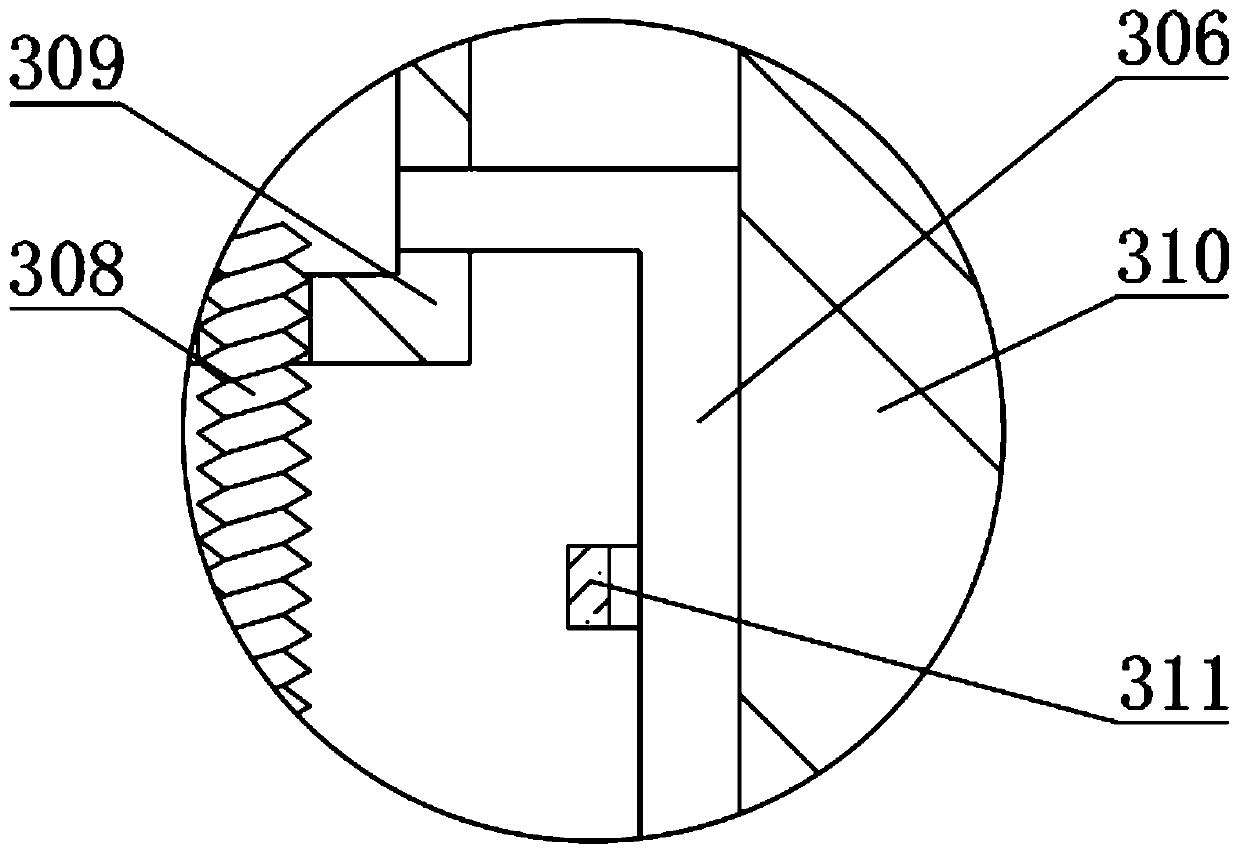

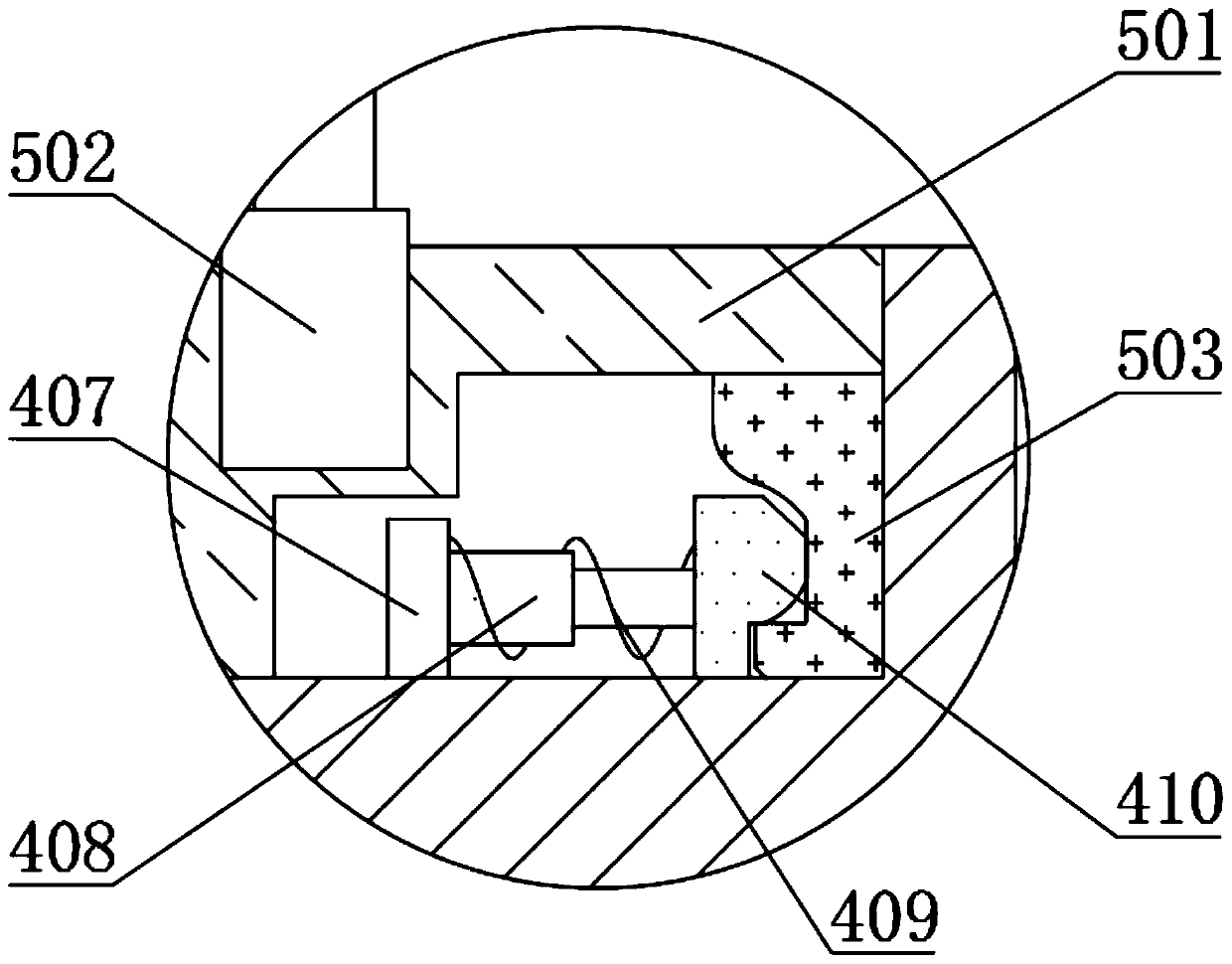

[0027] A welding manipulator for auto parts that is easy to replace clamps, comprising a main body 1 of a mechanical arm and a base 2, the bottom end of the main body 1 of the mechanical arm is fixedly connected to the base 2, and the top end of the base 2 is fixedly connected to a controller 6, and the controller 6 is connected to the top of the base 2. The main body 1 of the mechanical arm is fixedly connected, the top end of the base 2 is fixedly connected with a connecting device 4, the top end of the connecting device 4 is fixedly connected with a clamping device 5, the right end of the base 2 is fixedly connected with a flue gas treatment device 3, and the clamping device 5 includes a clamp Seat 501, first electric telescopic rod 502, card 503, connection seat 504, second electric telescopic rod 505, first clamping block 506, second clamping block 507, stopper 508, limit block 509, second spr...

Embodiment 2

[0030] The similarities between Embodiment 2 and Embodiment 1 will not be described in detail. The difference is that when the rod-shaped auto parts need to be welded, the staff pulls the connecting shaft 511 upward through the stopper 508, and then drives the limit through the connecting shaft 511. The block 509 slides upwards, so that the stopper 509 removes the interference to the second clamping block 507, and then the second clamping block 507 is taken out from the inner side of the first clamping block 506, and the concave surface of the second clamping block 507 is put in outwards. The inner side of the first clamping block 506, at the same time, the limiting block 509 is engaged with the second clamping block 507 through the draw-in groove inside the second clamping block 507, and then the rod-shaped auto parts can be adjusted by the second clamping block 507. Perform clamping and fixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com