High-performance environment-friendly injection molding panel pretreatment production line

An environmentally friendly, pre-treatment technology, applied in chemical instruments and methods, spray devices, cleaning methods and utensils, etc., can solve problems such as low cleaning efficiency and inability to achieve streamlined cleaning processes, to improve efficiency and convenience. , the effect of smooth return channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

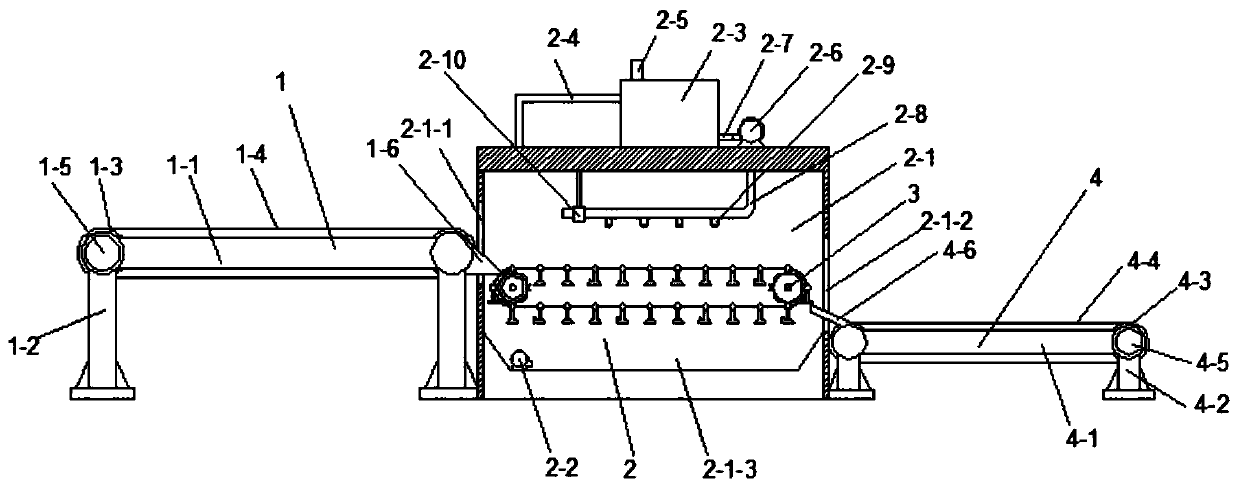

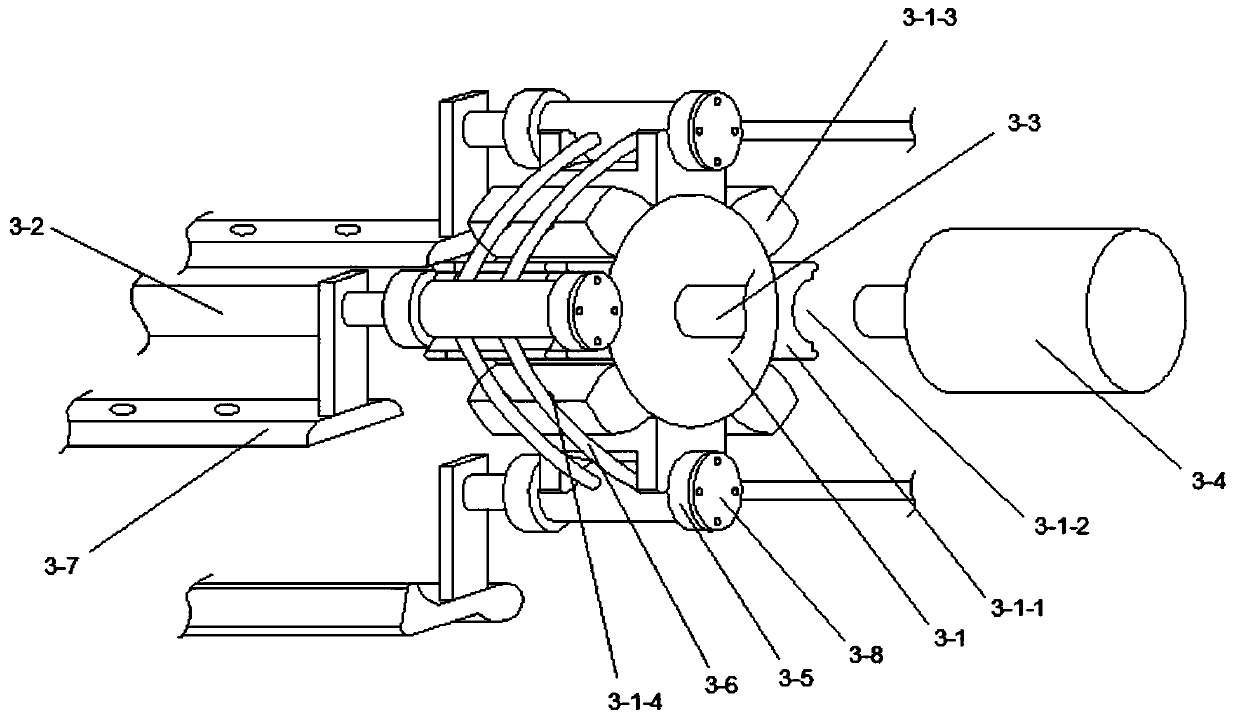

[0031] It can be seen from the accompanying drawings that a high-performance and environmentally friendly injection molding panel pretreatment production line includes an input device, a pretreatment device, a conveying device, and an output device;

[0032]The input device includes an input transmission frame, an input column, an input roller, an input belt and an input motor, and the input column is provided with the bottom end of the input transmission frame; the two ends of the input roller are rotated with the input transmission frame through bearings. The input belt is wrapped and arranged on the outer wall of the input roller; the input motor is arranged on one side of the input transmission frame, and realizes transmission with the input roller;

[0033] The pretreatment device is arranged at one end of the input device, and the pretreatment device includes a cavity, a circulation pump, a water tank, a water return pipe, a water inlet pipe, a spray pump, a water outlet ...

Embodiment 2

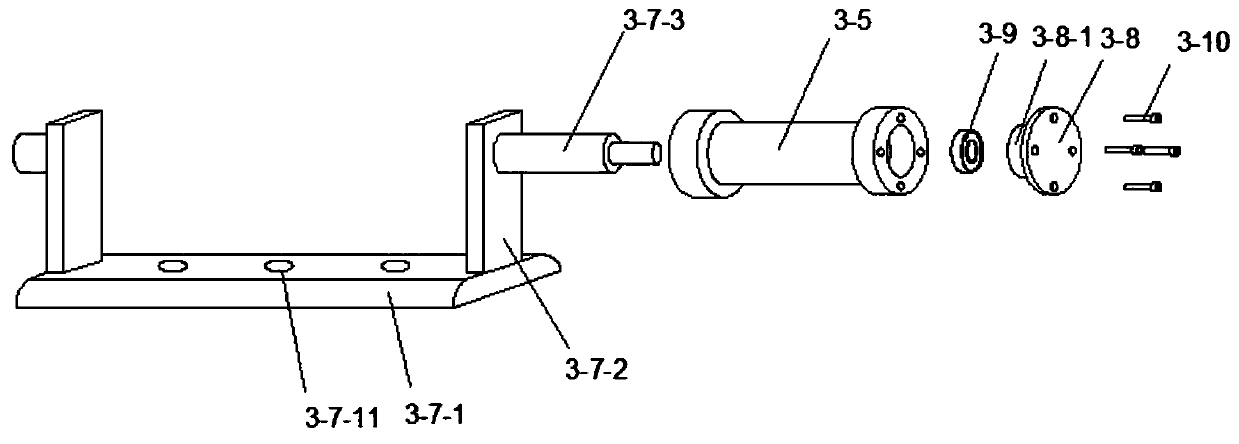

[0054] As can be seen in conjunction with the accompanying drawings, the difference between Embodiment 2 and Embodiment 1 is that the transmission row of Embodiment 2; the structure of every two transmission rows is a strip-shaped plate structure, and the top surface of the transmission row One side has a convex structure, forming a conveying row convex peak, and the conveying row convex peak is fixedly connected with the conveying row to form an integrated structure; one side of the bottom surface of the conveying row has a convex structure, forming a conveying row balance The balance block of the transmission row is fixedly connected with the transmission row to form an integral structure.

[0055] Further, the cross-section of the conveying row convex peak is in the shape of a peak with a narrow top and a wide bottom, and the two sides of the conveying row convex peak are arc-shaped.

[0056] Further, the cross-section of the balance weight of the conveying row is fan-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com