Energy absorbing type nut and automobile

A nut and stud technology, applied in the field of nuts for automotive electrical appliances, can solve the problems of reduced user experience, poor safety performance, short-circuit power failure of the whole vehicle, etc., to improve user experience, increase contact area, and reduce extrusion the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

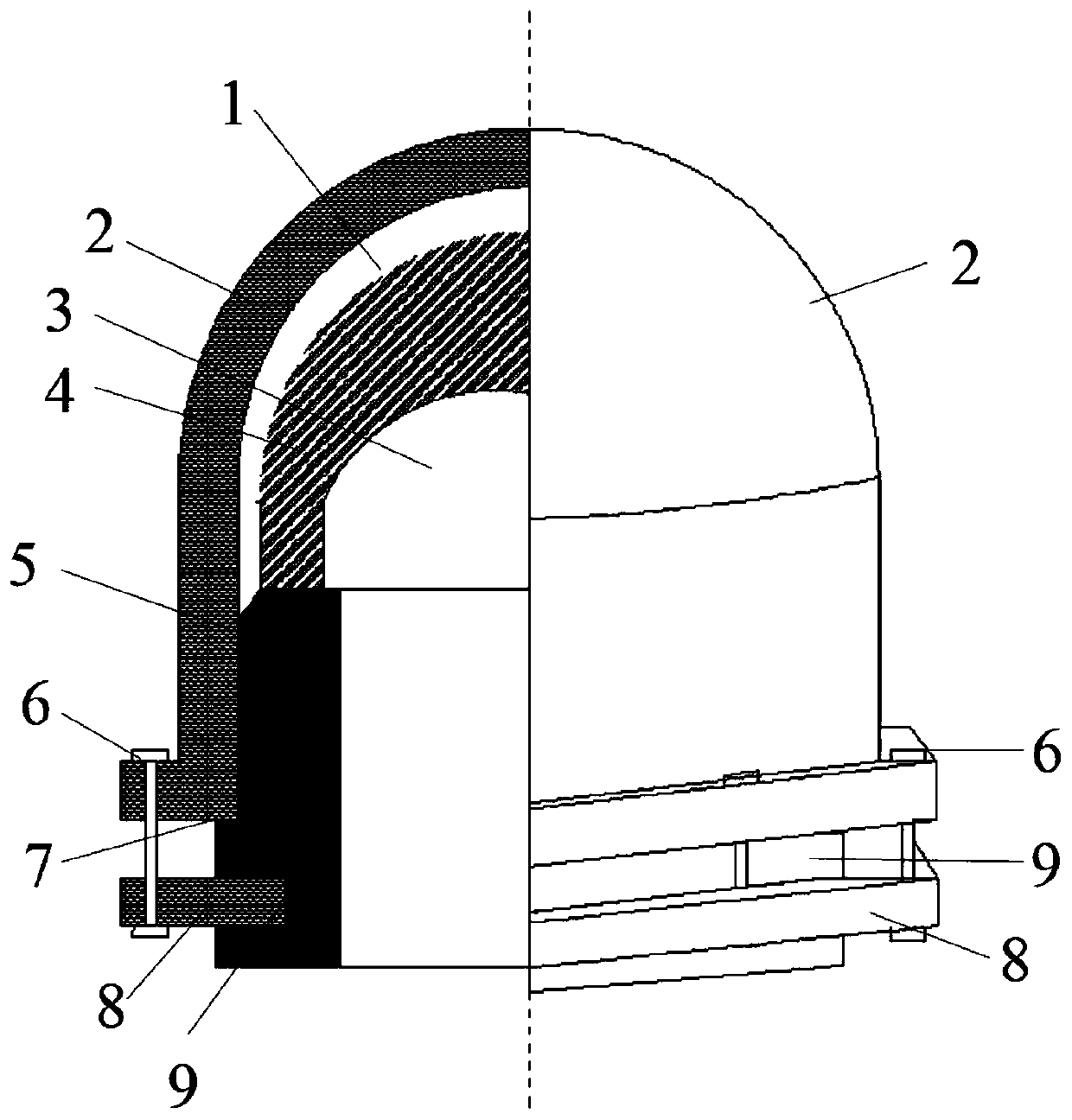

[0032] Such as figure 1 Shown: a crush nut, including a cover body 4, a locking part 5 and a housing 2;

[0033] The locking part 5 is provided with a locking cavity passing through the locking part 5 in the axial direction, and the locking cavity is used for connecting with studs or bolts;

[0034] The cover body 4 seals one end of the locking cavity, and the cover body 4 is fixedly connected with the locking part 5 to form a nut body;

[0035] The housing 2 is sleeved on the outer surface of the nut body and fixedly connected with the nut body;

[0036] A first cavity 1 is formed between the shell 2 and the outer surface of the nut body, and the shell 2 can be collapsed and deformed under the action of an external force; The direction-changed shell of the first cavity forms a collapsible nut, so that when the nut is squeezed, it can increase the contact area during extrusion, reduce the extrusion strength and stud penetration ability, and avoid extrusion During the proces...

Embodiment 2

[0058] Embodiment 2: be the preferred embodiment of embodiment 1

[0059] Such as figure 1 Shown: a crush nut, including a cover body 4, a locking portion 5 and a housing 2;

[0060] The locking part 5 is provided with a locking cavity passing through the locking part 5 in the axial direction, and the locking cavity is used for connecting with studs or bolts;

[0061] Preferably, an internal thread is provided on the inner wall of the locking part 5 close to the locking cavity; the locking cavity is threadedly fixed with a stud or a bolt.

[0062] The cover body 4 seals one end of the locking cavity, and the cover body 4 is fixedly connected with the locking part 5 to form a nut body;

[0063] The housing 2 is sleeved on the outer surface of the nut body and fixedly connected with the nut body;

[0064] A first cavity 1 is formed between the shell 2 and the outer surface of the nut body, and the shell 2 can be collapsed and deformed under the action of an external force; T...

Embodiment 3

[0090] An automobile, including a stud for automotive electrical appliances, and also includes a crush nut, which is used to connect with the stud for automotive electrical appliances; the crush nut embodiment 1 or 2 The above-mentioned collapsible nuts; this application designs the nuts on the electrical studs as collapsible cap nuts, which can not only prevent the studs from collapsing through the collapsible deformation of the collapsible cap nuts during the collision process. Strong penetrating ability in extrusion, and can protect the electric safety protection of the car in the process of collision to provide an improved design measure.

[0091] The collapsible nut disclosed by the present invention uses insulating material on the stud and designs the nut as a collapsible structure, which can not only increase the contact area during extrusion, but also reduce the extrusion strength and stud strength. Penetrating ability, and can avoid the direct contact between the live...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com