Highway pavement construction equipment and highway pavement construction method implemented by using same

A technology for construction equipment and roads, applied in metal processing equipment, casting molding equipment, roads, etc., can solve the problems of poor cleaning effect, cleaning tools, affecting service life and effect, and dust pollution in the surrounding environment, so as to achieve good planing effect, The effect of reducing direct hard collisions and reducing transshipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

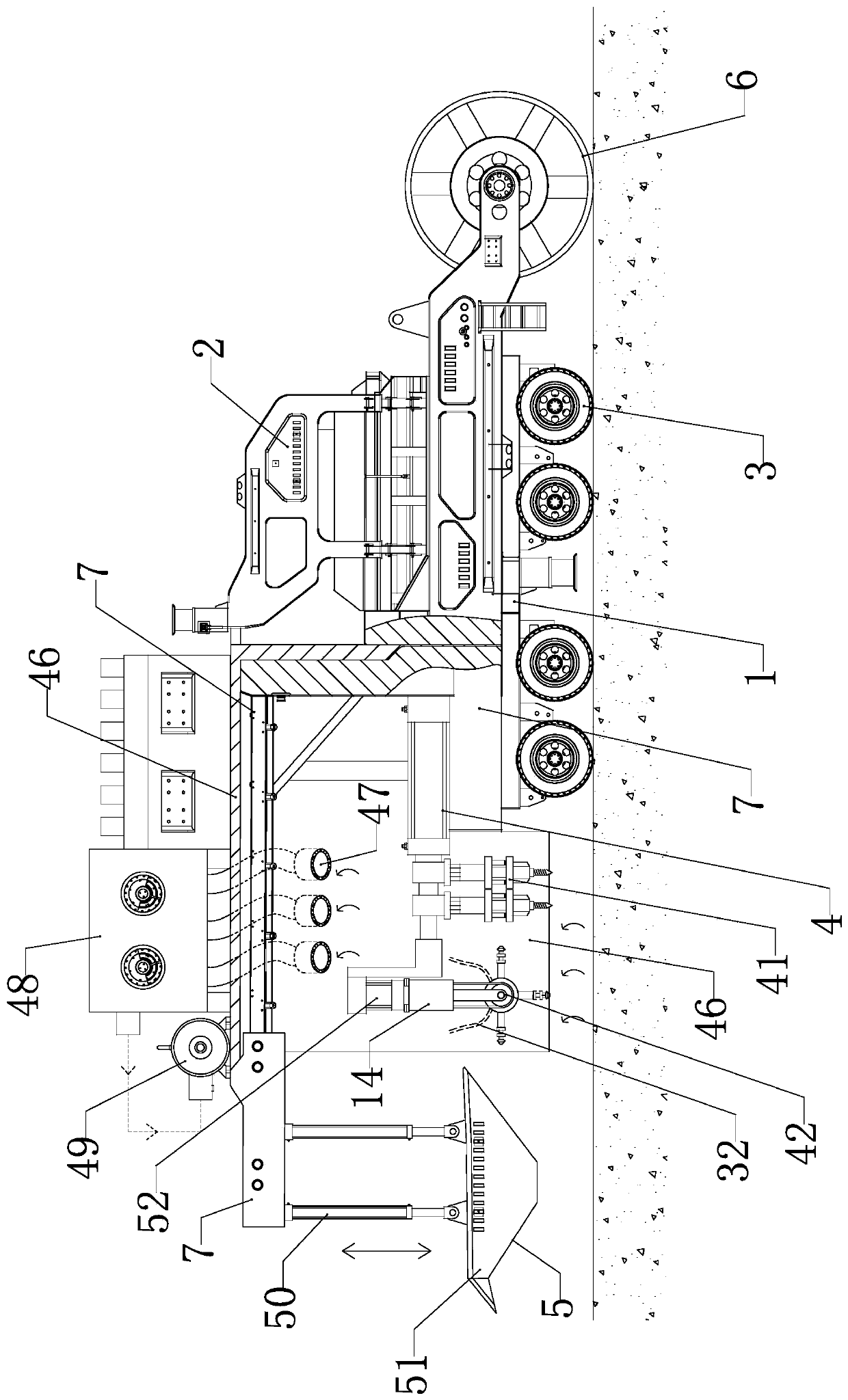

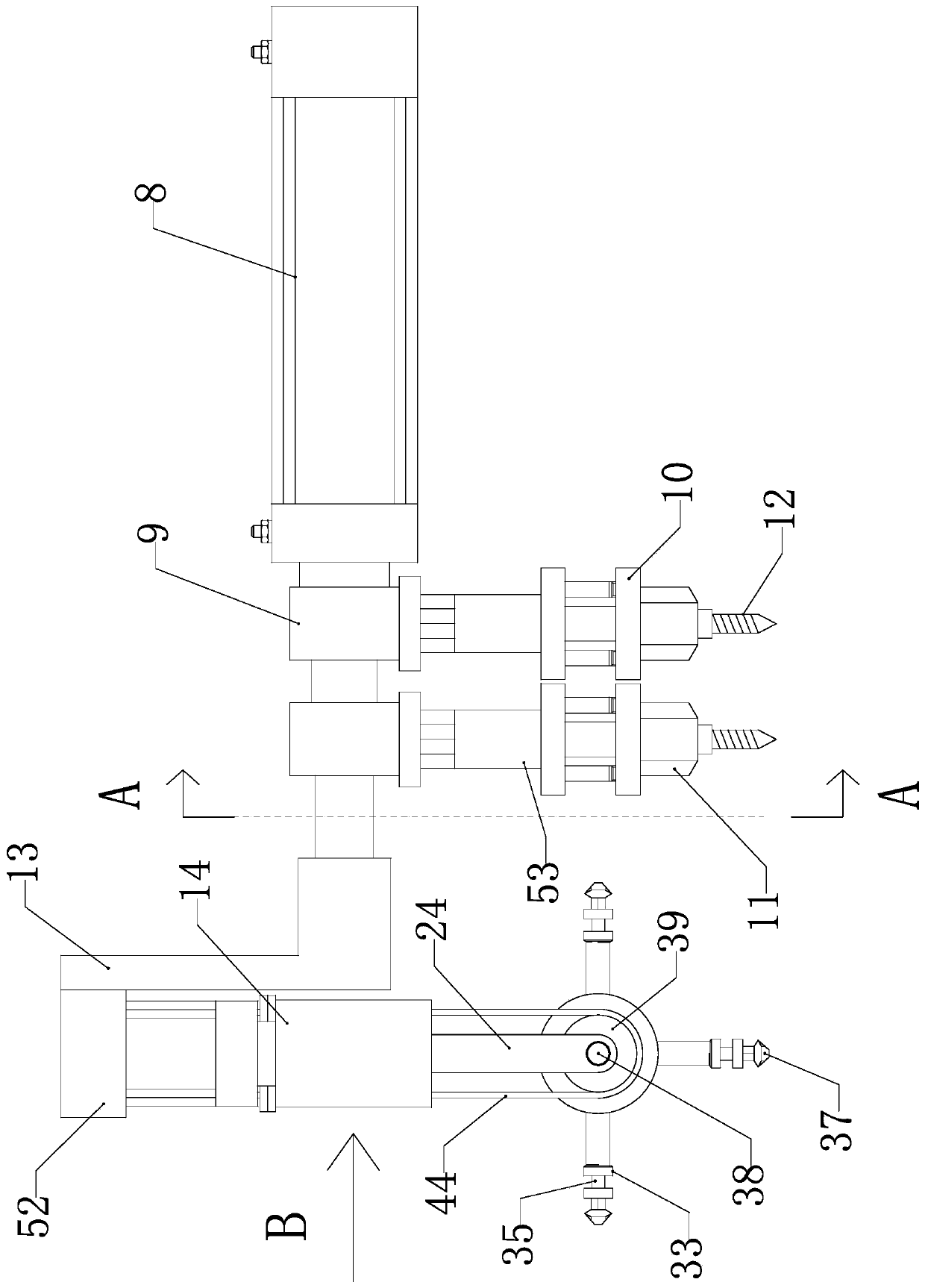

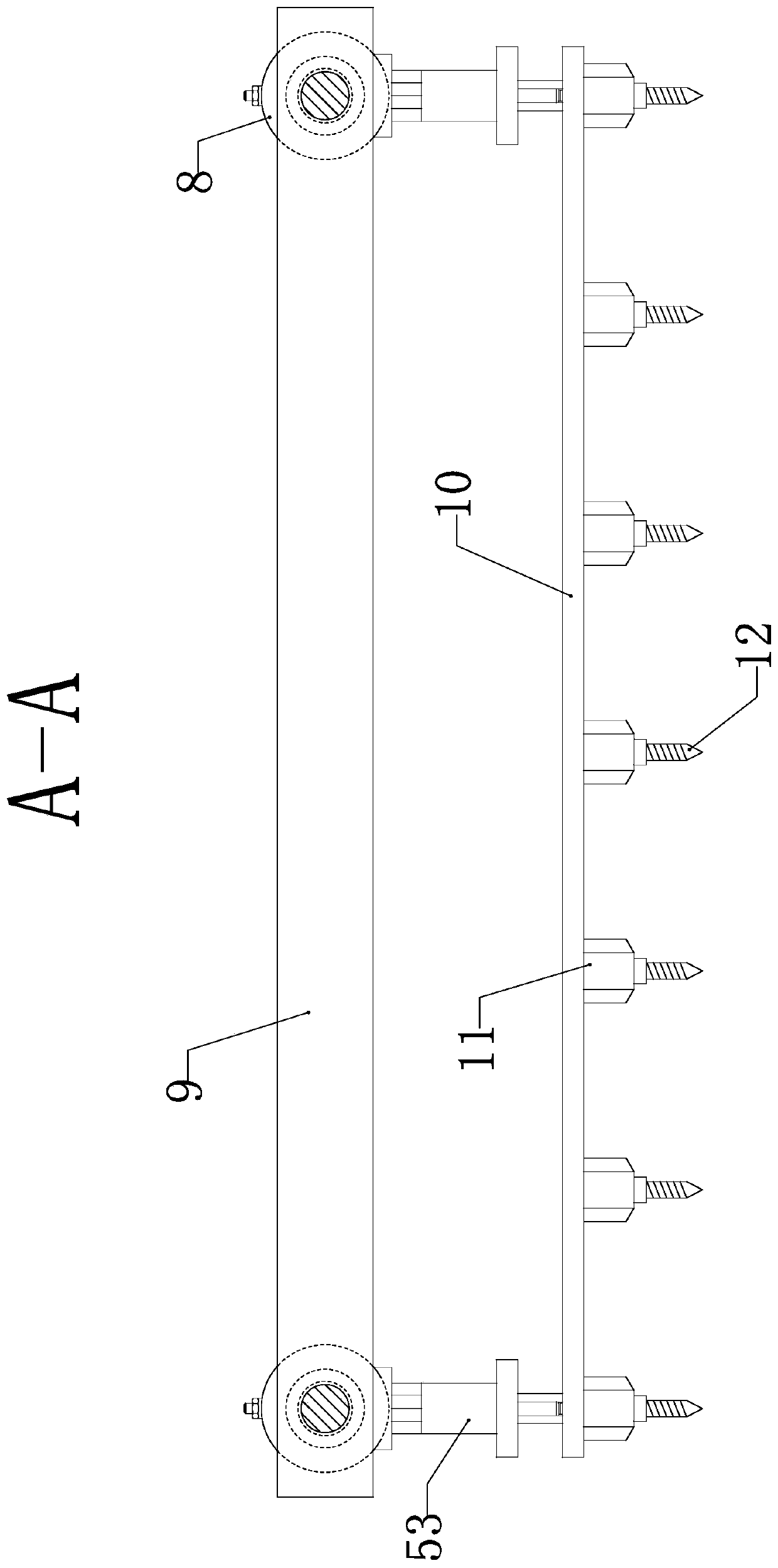

[0052] Such as Figure 1-9 As shown in , the highway pavement construction equipment includes a driving chassis assembly 1, a cab 2, and several driving wheels 3, the cab 2 is arranged on the top of the front side of the driving chassis assembly 1, and the driving wheels 3 Installed below the drive chassis assembly 1, the front end of the drive chassis assembly 1 is equipped with an adjustable planing device 4 for planing and cleaning the waste road surface, and the downstream of the planing device 4 cooperates A waste collection device 5 is installed, and the waste collection device 5 is used to collect and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com