Method for preparing nickel-vanadium sputtering target material

A sputtering target, nickel-vanadium technology, applied in the field of nickel-vanadium sputtering target preparation, to achieve the effect of compact structure without pores, fine and uniform grains, and high sputtering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The purity of raw materials is 99.95% (3N5) The nickel vanadium ingot carries out the following process steps:

[0020] Step 1) hot forging the nickel vanadium ingot. The holding temperature before hot forging is 1250±50°C, and the holding time is 1h-2h. After being out of the furnace, the nickel-vanadium ingot is roughly drawn and lengthened along the axial pier for more than 3 times, and air-cooled after the forging is completed;

[0021] Step 2) annealing the blank of step 1). The annealing temperature is 850±50°C, and the annealing time is 1-2h.

[0022] Step 3) rolling and deforming the billet in step 2). The total cold deformation rate is 85±5%, and the cold deformation method is cross rolling, wherein the rolling pass deformation is controlled at 7-15%.

[0023] Step 4) Perform annealing treatment on the billet of step 3), the annealing temperature is 900°C±50°C, and the annealing time is 1-2h.

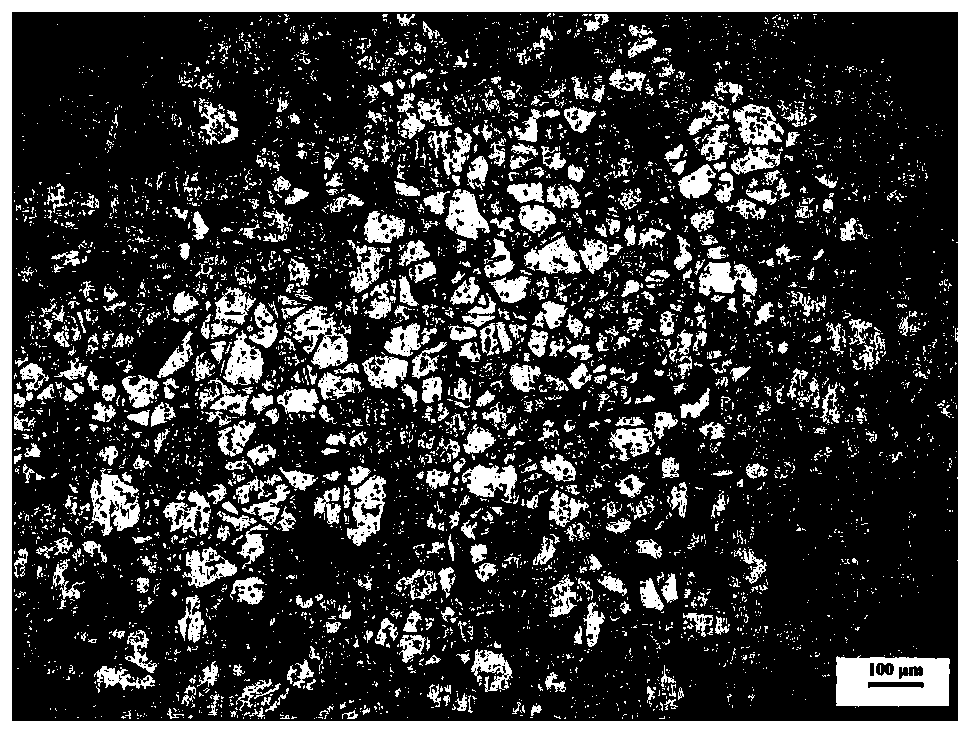

[0024] Sampling and analyzing the microstructure of the bill...

Embodiment 2

[0026] The purity of raw materials is 99.95% (3N5) The nickel vanadium ingot carries out the following process steps:

[0027] Step 1) hot forging the nickel vanadium ingot. The holding temperature before hot forging is 950±50°C, and the holding time is 3h-4h. After being out of the furnace, the nickel-vanadium ingot is roughly drawn and lengthened along the axial pier for more than 3 times, and air-cooled after the forging is completed;

[0028] Step 2) annealing the blank of step 1). The annealing temperature is 950±50°C, and the annealing time is 1-2h.

[0029] Step 3) rolling and deforming the billet in step 2). The total cold deformation rate is 70±5%, and the cold deformation method is cross rolling, wherein the rolling pass deformation is controlled at 7-15%.

[0030] Step 4) Perform annealing treatment on the billet of step 3), the annealing temperature is 700°C±50°C, and the annealing time is 2-3h.

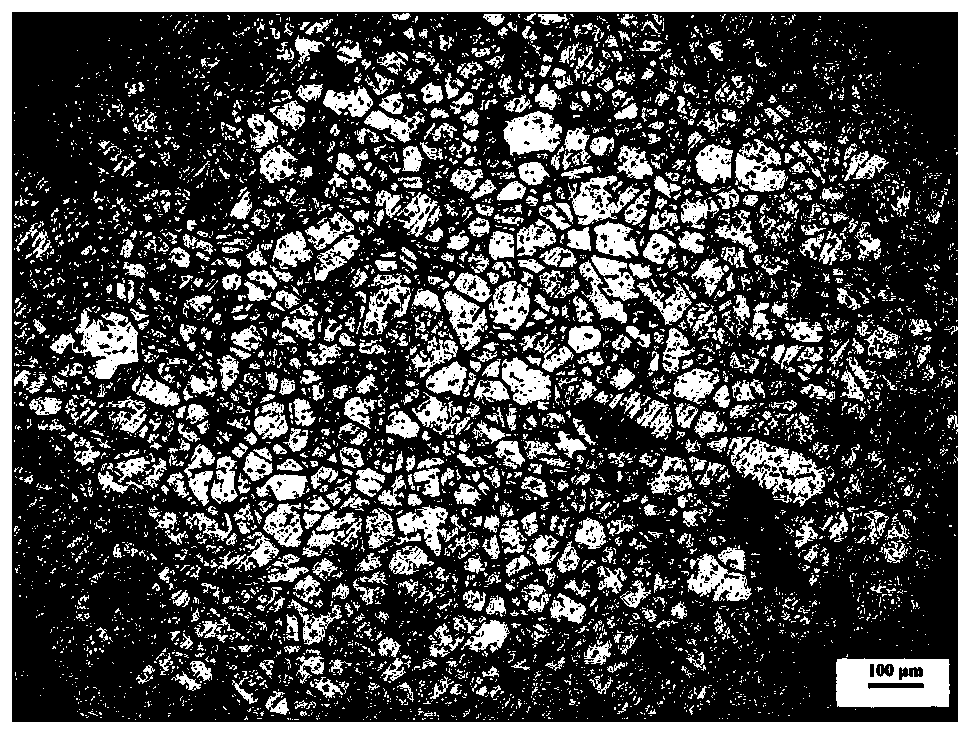

[0031] Sampling and analyzing the microstructure of the bille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com