An intensified method for denitrification by ammonia spraying in the production process of iron ore pellets

A pelletizing and iron ore technology, which is applied in the strengthening field of ammonia injection denitrification in the production process of iron ore pellets, can solve the problems of prolonging the denitrification reaction time, short reaction time of iron-containing minerals, and low denitrification efficiency, so as to improve the denitrification efficiency , Improve dehydration efficiency and reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

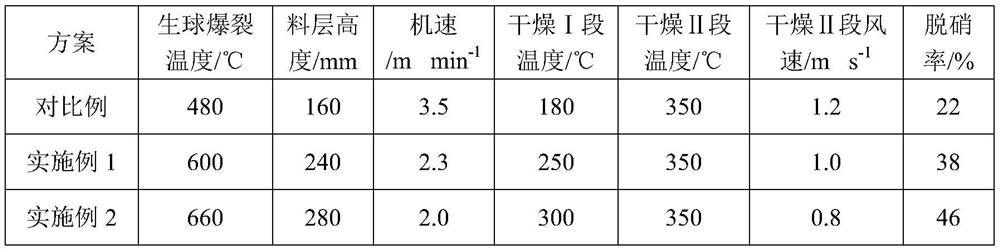

Embodiment 1

[0026] Add the anti-burst additive in bentonite, the ratio is 1% of bentonite, additive is sodium carboxymethyl starch: cationic polyacrylamide: the compound of sodium carboxymethyl cellulose, the ratio of the three is 2:3:5, will Mix bentonite and additives thoroughly, then add 1.2% to iron concentrate to prepare pellets, the bursting temperature of green pellets is increased from 480°C to 600°C; the chain grate-rotary kiln pellet production process is adopted, and the thickness of the material layer is 240mm , the speed of the grate machine is 2.3m / min, the drying of the pellets adopts two-stage drying, the first stage is blast drying, the temperature is increased from the conventional 180°C to 250°C, and the dehydration rate of the first stage of the drying is increased from 32%. to 50%; Stage II is exhaust drying, the drying temperature is 350°C, and the wind speed is reduced from the conventional 1.2m / s to 1.0m / s. Pipelines are installed in the fume hood of the drying sec...

Embodiment 2

[0028] Add the anti-burst additive in bentonite, the ratio is 3% of bentonite, additive is sodium carboxymethyl starch: cationic polyacrylamide: the compound of sodium carboxymethyl cellulose, the ratio of the three is 4:4:7, will The bentonite and additives are fully mixed, finely ground and modified, and then 1.2% is added to the iron concentrate to prepare pellets. The burst temperature of the green pellets is increased from 480°C to 660°C; the chain grate-rotary kiln pellet production process is adopted, The thickness of the material layer is 280mm, the speed of the grate machine is 2.0m / min, the drying of the pellets adopts two-stage drying, the first stage is blast drying, the temperature is increased from the conventional 180°C to 300°C, and the first stage of drying is dehydrated The drying rate is increased from 32% to 59%; the second stage is exhaust drying, the drying temperature is 350°C, and the wind speed is reduced from the conventional 1.2m / s to 0.8m / s. Pipelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com