Experiential salt sculpture manufacturing method

An experiential salt carving technology, which is applied in decorative arts and decorative structures, can solve the problems of short storage time, difficulty in painting and preservation of salt handicrafts, and achieve rich artistic characteristics of products, fine and sharp appearance lines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

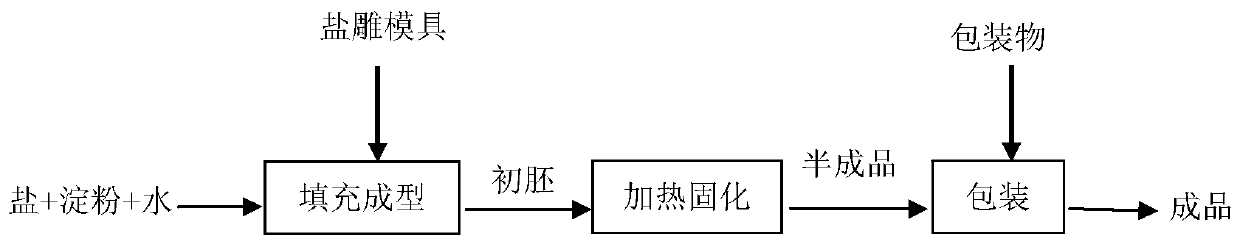

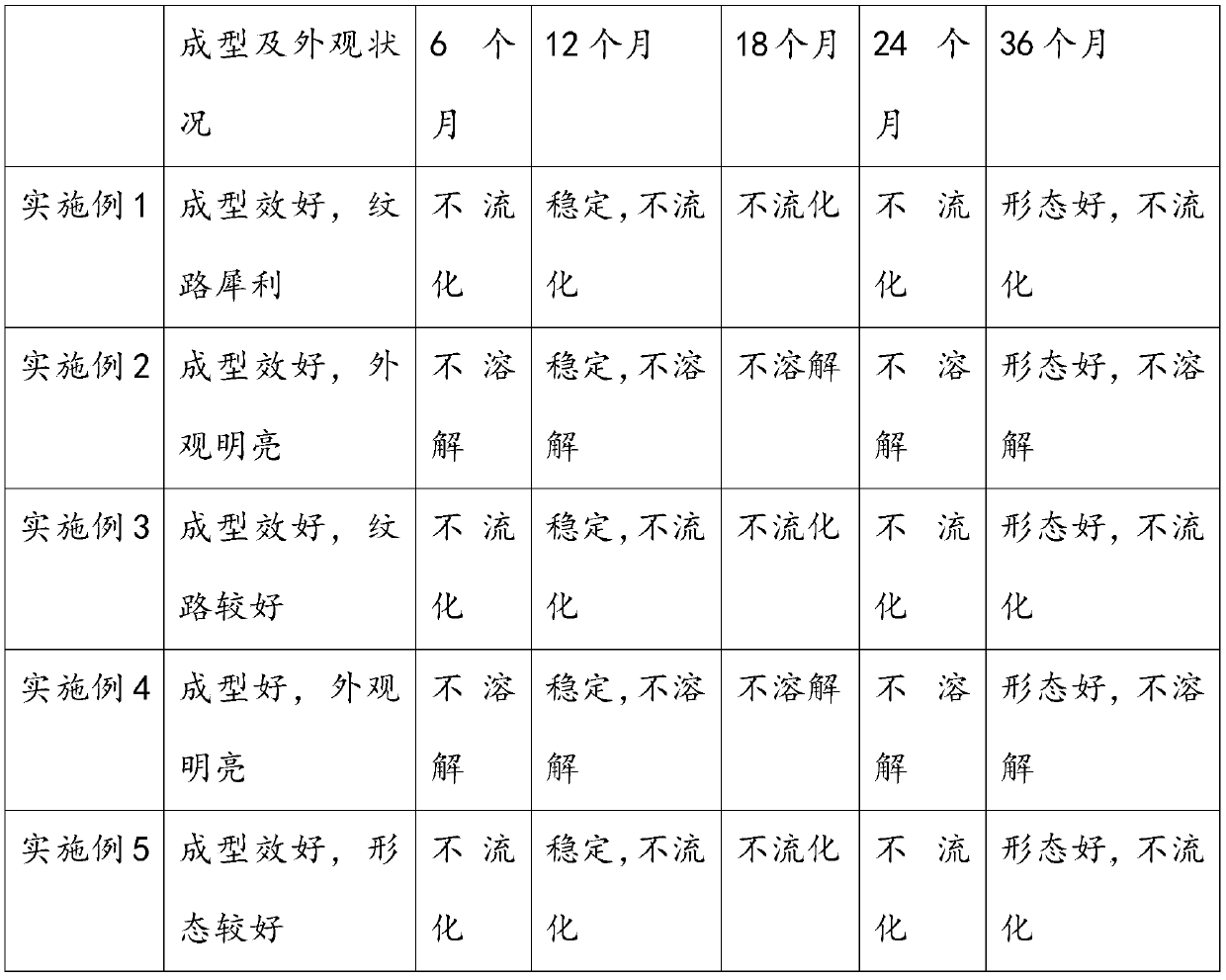

Embodiment 1

[0029] Mix refined granule salt, binder (starch) and water into molding raw materials; wherein binder accounts for 6%, water accounts for 0.8%, and the balance is refined granule salt, and the sum of the total mass percentage is 100%. Choose a prefabricated silicone mold, first fill the small corners of the mold with some molding materials, and then use the molding materials to fill the rest of the mold, fix the mold, prevent the mold from deforming, and form the initial embryo of salt carving, put it into the specification model 2500W Heat it in a microwave oven with high heat until solidified, take it out and let it cool, and demould it to be the initial salt carving product; then simply remove the burrs and burrs from the initial product, and pack it to get the salt carving product.

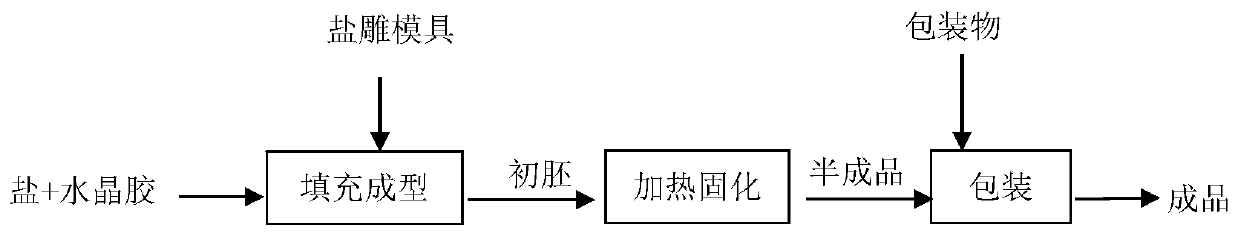

Embodiment 2

[0031] Refined granular salt and crystal gel are mixed to form molding raw materials, crystal gel accounts for 15% in the molding raw material, the balance is refined granular salt, and the sum of the total mass percentages of the molding raw materials is 100%. Choose a prefabricated silicone mold, first fill the small corners of the mold with some molding materials, and then use the molding materials to fill the remaining parts of the mold, fix the mold, prevent the mold from deforming, form the initial embryo of salt carving, and put it into the blast Dry and solidify in a drying oven at 80°C, take it out and let it cool, and demould it to be the initial salt carving product; then simply deburr and pack the initial product to obtain the salt carving product.

Embodiment 3

[0033] Mix refined granule salt, binder (starch) and water into molding raw material, in this molding raw material, binder accounts for 13%, water accounts for 1.3% ratio, and the balance is refined granule salt, and the sum of total mass percentage is 100%. Choose a prefabricated silicone mold, first fill the small corners of the mold with some molding materials, and then use the molding materials to fill the remaining parts of the mold, fix the mold, prevent the mold from deforming, form the initial embryo of salt carving, and put it into the specification model Heat it in a 2500W microwave oven with high heat until it solidifies, take it out and let it cool, and demould it to be the initial salt carving product; then simply remove the burrs and burrs from the initial product, and pack it to get the salt carving product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com