Multi-station self-positioning floating clamping and workpiece self-overturning intelligent tool clamp system

A technology of floating clamping and tooling fixtures, applied in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve problems such as low production efficiency, poor practicability, complex structure, etc., to improve workpiece production efficiency, ensure safety, reduce Participation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

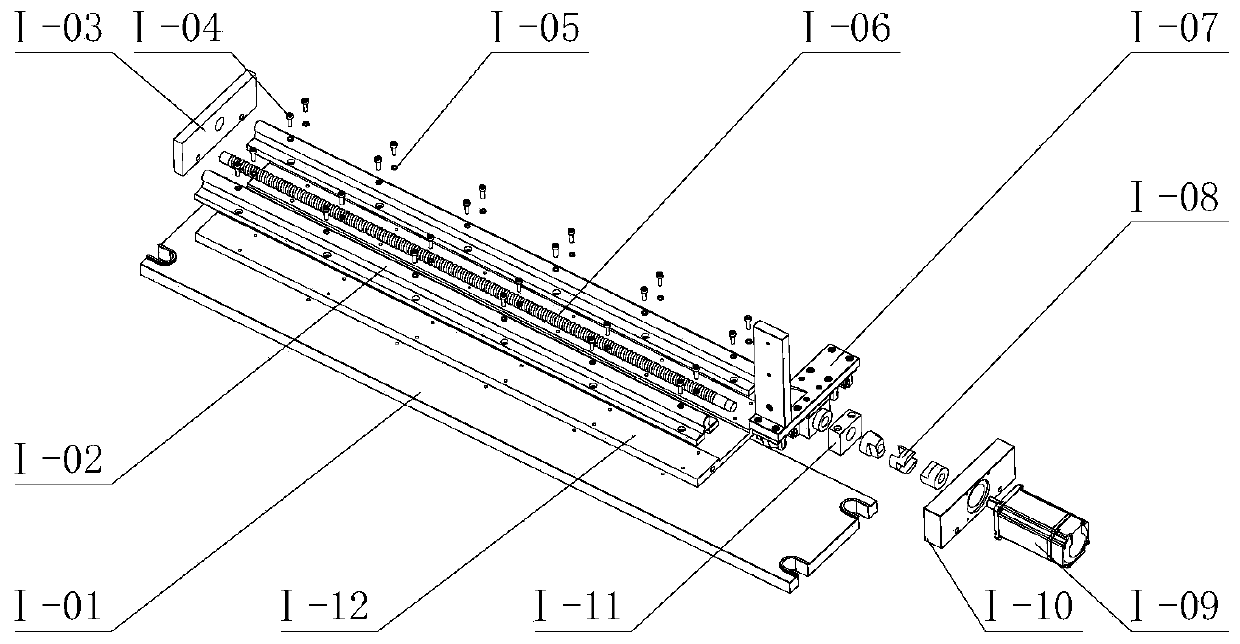

[0117] Attached below figure 1 - attached Figure 26 (b) Further explain the clamp system disclosed in this embodiment;

[0118] Refer to attached figure 1 As shown, the multi-station self-positioning floating clamping and workpiece self-turning intelligent fixture system consists of four parts: linear motion device I, workpiece self-turning device II, self-positioning floating clamping device IV, and industrial camera V. Linear motion device I It is installed under the workpiece self-turning device II, and the linear motion device drives the workpiece self-turning device to move horizontally. The workpiece III is placed on each station of the self-positioning floating clamping device IV, and the self-positioning floating clamping device IV and the linear motion device I and the workpiece self-turning device II are placed relatively parallel. Among them, the linear motion device I and the self-positioning floating clamping device IV are fixed on the working platform of the ...

Embodiment 2

[0139] This embodiment discloses the second self-positioning clamping method, which can realize the same function as the self-positioning floating clamping device IV, such as Figure 28 As shown, the bottom plate VI-01 is fixed on the milling machine table through four T-shaped bolts VI-05 and hexagon nuts. There is a positioning support component VI-02 at the left end of the self-positioning floating clamping device, and a positioning support component VI- 02 is fixed on the bottom plate VI-01 by hexagon socket head screws, two linear guide rails VI-07 are fixed on the bottom plate VI-01 by hexagon socket head screws, positioning and floating clamping assembly VI-03 and floating pressing assembly VI-04 can slide left and right on the linear guide rail VI-07, and the hydraulic cylinder VI-06 moves to the left by hydraulically pushing the floating and pressing component VI-04, pressing the workpiece III, and the workpiece III transmits the thrust to the positioning and floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com