Inner cylinder wall forming machine

A technology of forming machine and inner cylinder wall, applied in the field of assembly and manufacturing, can solve the problems of inability to realize automatic transfer and accurate positioning, and achieve the effect of realizing automatic forming, simplifying processing flow and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

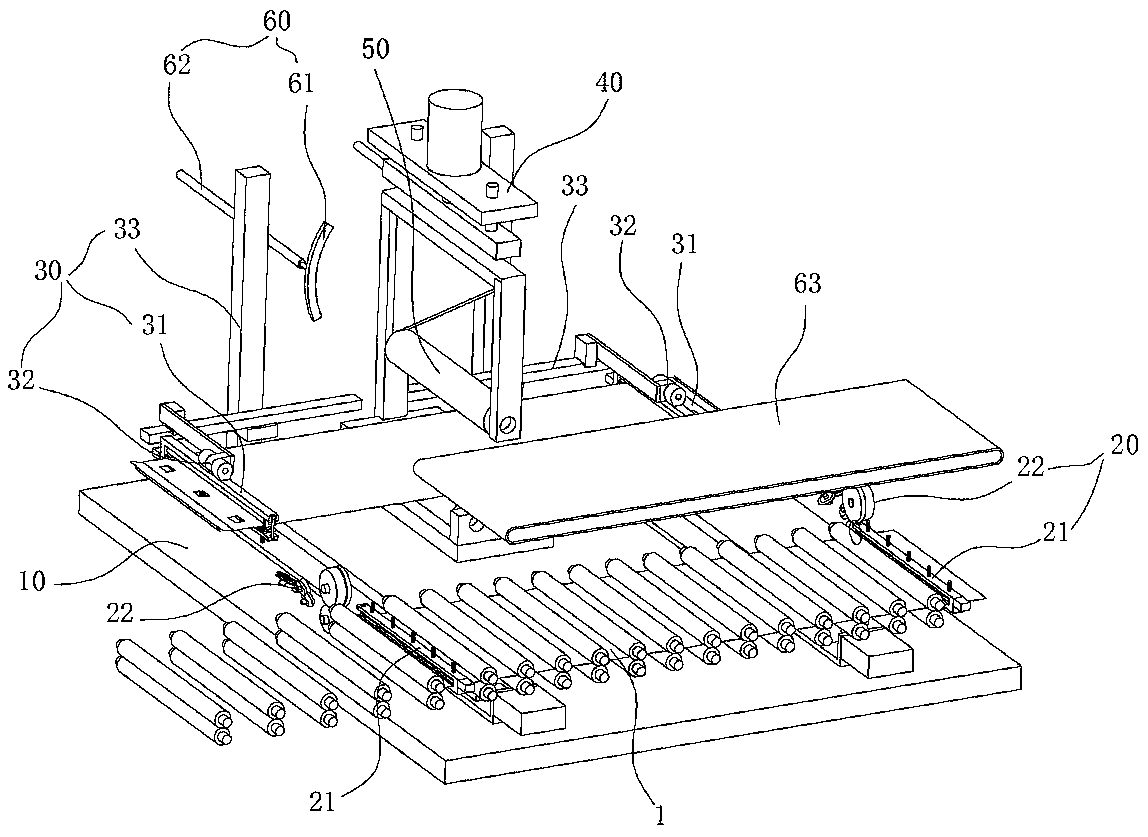

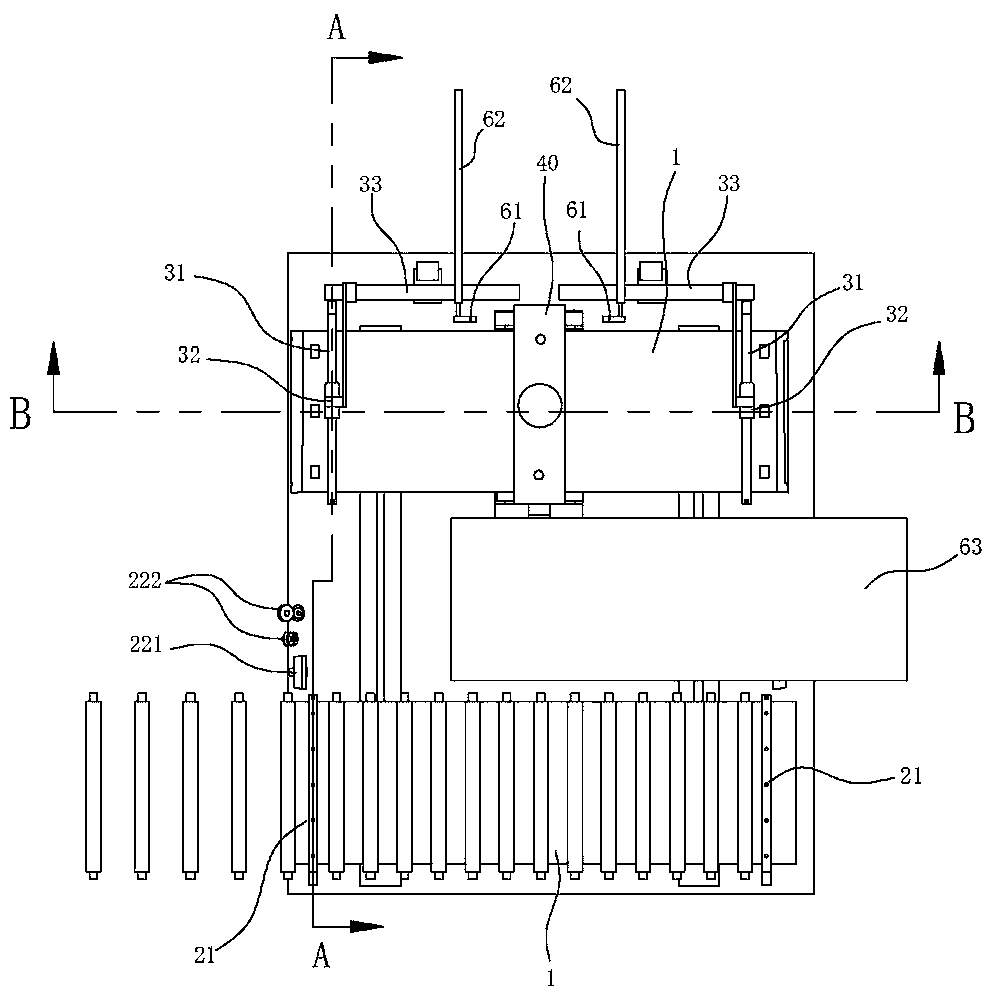

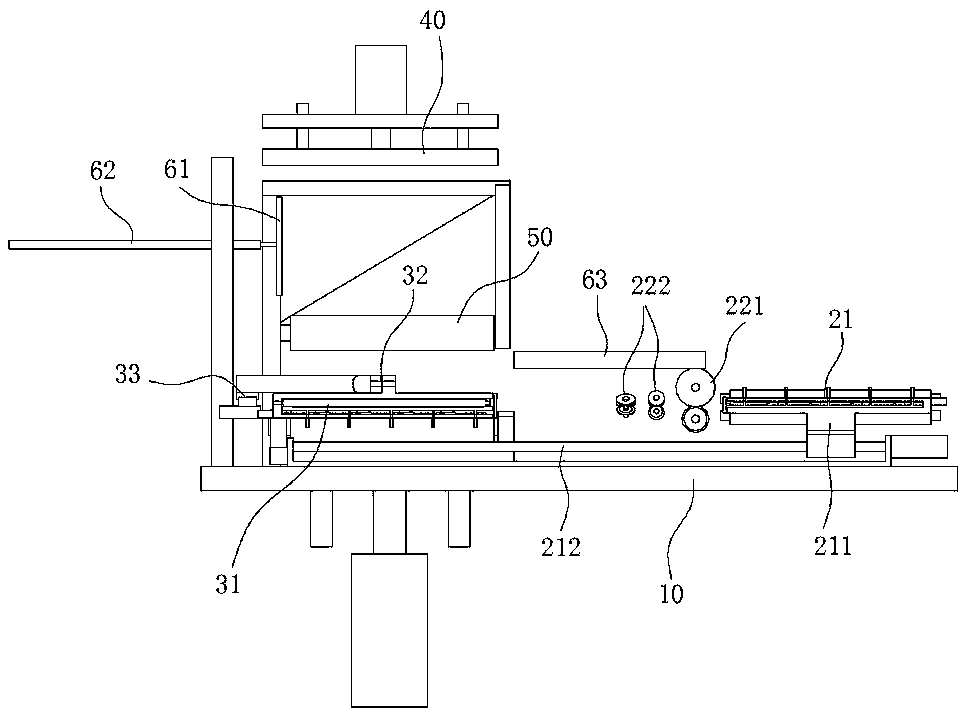

[0028] Such as figure 1 , 2 As shown, an inner cylinder wall forming machine includes a hemming mechanism 20, an overturning mechanism 30, a buckle seam mechanism 40 and a shaping mechanism 50, and the hemming mechanism 20 is used to bend the two ends of the plane sheet 1 into a V shaped bayonet and transport the plane sheet 1 to the turning mechanism 30, the turning mechanism 30 is used to turn the two ends of the plane sheet 1 by 180° respectively and make the two ends butt joint at the buckle seam mechanism 40, the buckle The sewing mechanism 40 is used to crimp and fix the two ends of the planar sheet 1 so that the sheet is connected into an annular tube 2 , and the shaping mechanism 50 is used to roll the annular tube 2 into a cylindrical shape. The invention integrates the rolling and seaming mechanism 40 of the cylindrical part, and adjusts the processing sequence, that is, first seams and then shaping, which solves the defect that the thin-walled parts are not suitabl...

Embodiment 2

[0040] A tube forming method using the above forming machine, comprising the steps of:

[0041] Step 1: blanking, cutting the metal strip into a rectangular flat sheet 1;

[0042] Step 2: embossing, punching the concave-convex structure and mounting holes on the flat sheet 1 according to the design requirements;

[0043] Step 3: Folding, conveying the flat sheet 1 to the folding mechanism 20, and using the folding mechanism 20 to bend the two ends of the flat sheet 1 into a V-shaped bayonet;

[0044] Step 4: Overturning, conveying the flat sheet 1 after flanging to the overturning mechanism 30, using the overturning mechanism 30 to turn over the two ends of the flat sheet 1 by 180°, and transferring the V-shaped bayonets at the two ends to the buckle seam mechanism 40 buckle at;

[0045] Step 5: buckle the seam, use the buckle seam mechanism 40 to rivet the fastening area of the V-shaped bayonet, so that the two ends of the flat sheet 1 are fixed to form the annular tube 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com