Degradable ureteral stent and manufacturing method thereof

A ureteral stent tube and technology of degradable materials, applied in the field of degradable ureteral stent tube and its production, can solve the problems of loss or even need to remove the kidney, bleeding and tissue damage, poor tissue compatibility, etc., and achieve good mechanical support performance, degradation The effect of prolonging the speed and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

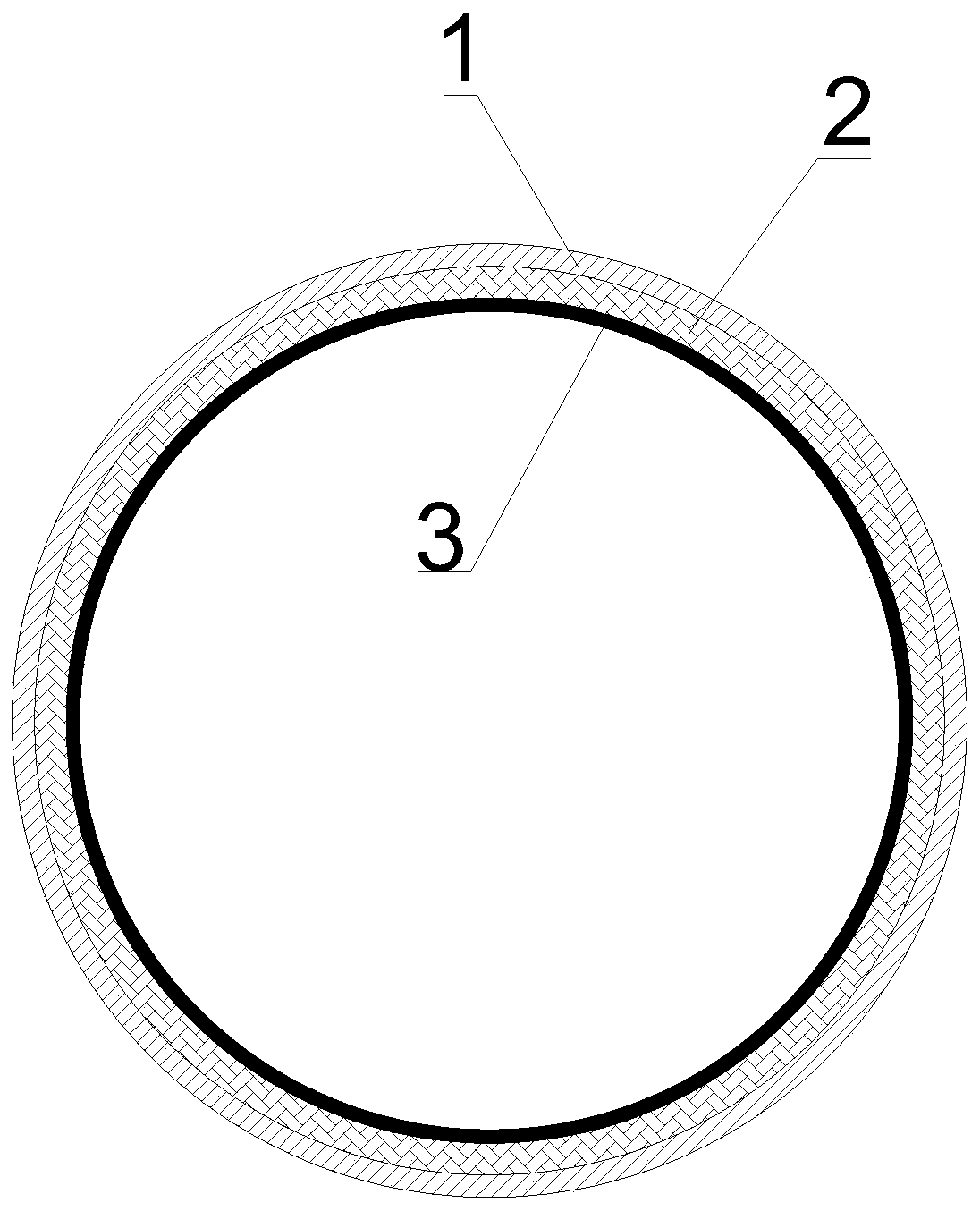

[0036] Such as figure 1 As shown, the degradable ureteral stent tube in the present invention consists of a polycaprolactone outer membrane layer 1, a polyglycolide fiber and a polyglycolide-lactide fiber braided layer 2, L-lactide-ε- Caprolactone copolymer / graphene inner film layer 3 composition.

[0037] The graphene layer of the inner film layer 3 is a single-layer graphene with a thickness of 0.3 nm, and the thickness of each L-lactide-ε-caprolactone copolymer layer is 0.1 μm.

[0038] The preparation method of the inner film layer 3 includes: (1) attaching the L-lactide-ε-caprolactone copolymer solution to the graphene / copper sheet side with graphene by spin coating or casting, and dry it naturally 10h; then the copper sheet was etched in ammonium persulfate solution and etched for 8h at room temperature to obtain L-lactide-ε-caprolactone copolymer / graphene film; (2) L-lactide-ε -Transfer the caprolactone copolymer / graphene film to the surface of the graphene / copper sheet, s...

Embodiment 2

[0047] The degradable ureteral stent tube in the present invention is composed of polylactic acid outer membrane layer 1, polydioxanone fiber and polytrimethylene carbonate fiber braided layer 2, L-lactide-ε-caprolactone copolymer / Graphene inner film layer 3 composition.

[0048] The graphene layer of the inner film layer 3 is a single-layer graphene with a thickness of 0.4 nm, and the thickness of each L-lactide-ε-caprolactone copolymer layer is 1 μm.

[0049] The preparation method of the inner film layer 3 includes: (1) attaching the L-lactide-ε-caprolactone copolymer solution to the graphene / copper sheet side with graphene by spin coating or casting, and dry it naturally 10h; then the copper sheet was etched in ammonium persulfate solution and etched for 8h at room temperature to obtain L-lactide-ε-caprolactone copolymer / graphene film; (2) L-lactide-ε -Transfer the caprolactone copolymer / graphene film to the surface of the graphene / copper sheet, so that the L-lactide-ε-caprol...

Embodiment 3

[0058] The degradable ureteral stent tube of the present invention is composed of polyglycolide outer membrane layer 1, polyhydroxy fatty acid ester fiber and polylactic acid-glycolic acid copolymer fiber braided layer 2, L-lactide-ε-caprolactone Copolymer / graphene inner film layer 3 composition.

[0059] The graphene layer of the inner membrane layer 3 is a single-layer graphene with a thickness of 0.35 nm, and the thickness of each L-lactide-ε-caprolactone copolymer layer is 2 μm.

[0060] The preparation method of the inner film layer 3 includes: (1) attaching the L-lactide-ε-caprolactone copolymer solution to the graphene / copper sheet side with graphene by spin coating or casting, and dry it naturally 10h; then the copper sheet was etched in ammonium persulfate solution and etched for 8h at room temperature to obtain L-lactide-ε-caprolactone copolymer / graphene film; (2) L-lactide-ε -Transfer the caprolactone copolymer / graphene film to the surface of the graphene / copper sheet, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com