Direct-current arc plasma power supply and system

A plasma and DC arc technology, which is applied in the direction of converting AC power input to DC power output, electrical components, and output power conversion devices, etc., can solve the problem of inability to meet high voltage requirements during arc starting, and achieve high power conversion efficiency. , the effect of increasing the high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] Example of DC arc plasma system:

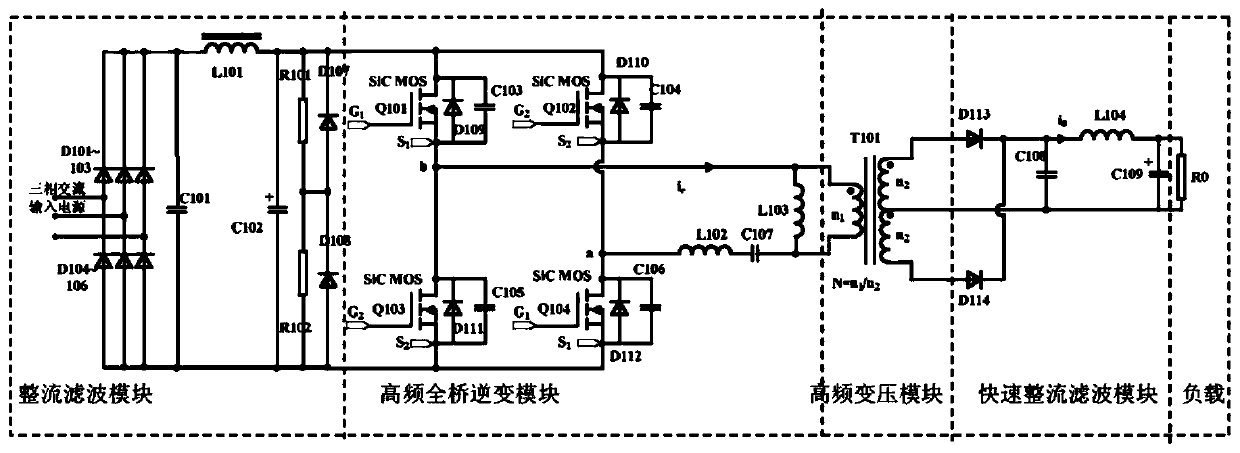

[0023] This embodiment provides a DC arc plasma system, the system includes a DC arc plasma power supply (hereinafter referred to as the power supply) and an arcing load, the power supply output end of the power supply is connected to the arcing load, so that the DC arc plasma power supply generates The AC signal is sent to both ends of the arcing load, causing the non-conductive gas to break down, thereby forming a conductive channel to generate arc discharge. The arcing load here can be a plasma torch or a graphite electrode.

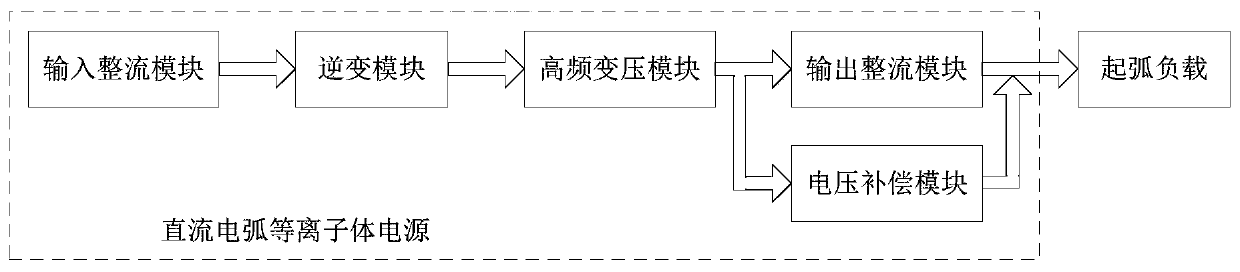

[0024] Its structural connection diagram is as follows figure 2 shown.

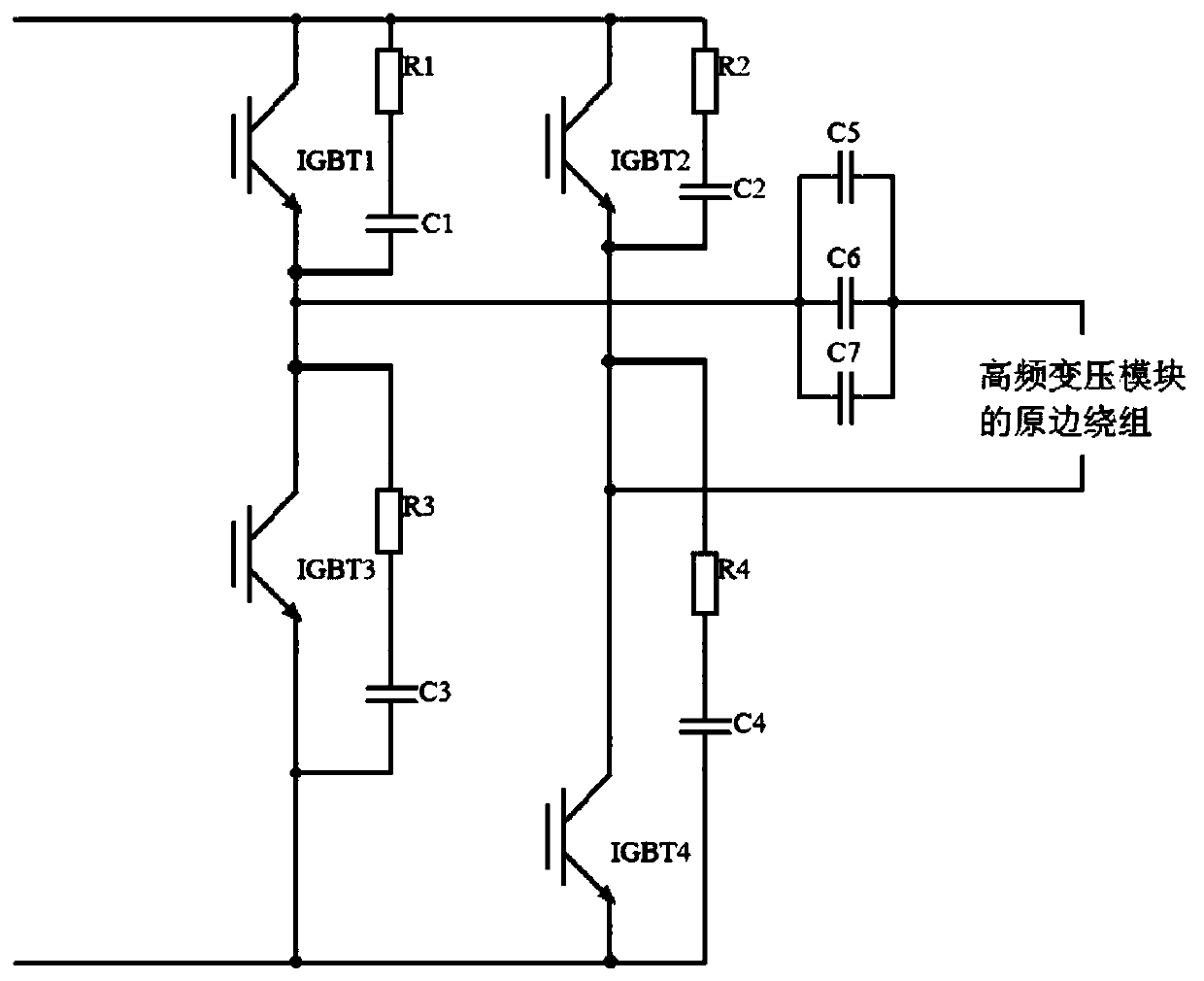

[0025] like figure 2 As shown, the power supply includes an input rectifier module, an inverter modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com