Texturing and cleaning method of heterojunction solar cell

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unclean cleaning, affecting the electrical performance of the cell, and insufficient reaction, so as to improve the passivation effect and reduce the EL defect. rate, improve the effect of Voc and FF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

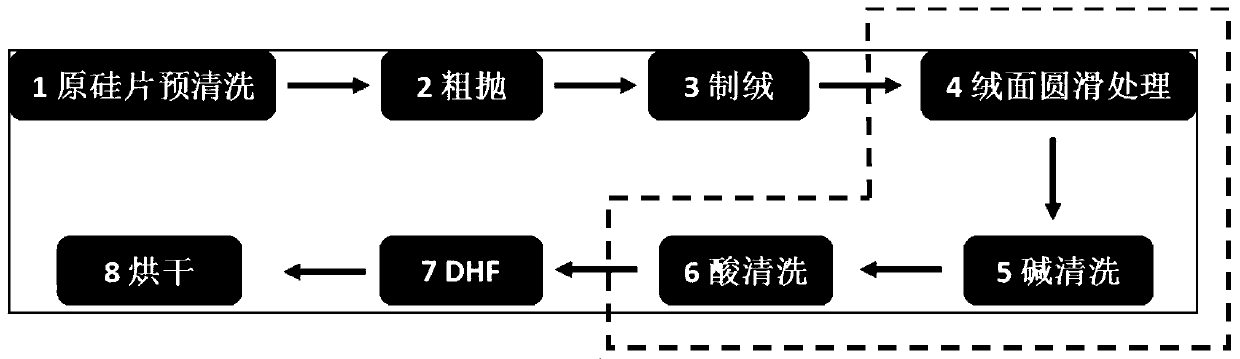

[0039] A method for fabricating and cleaning heterojunction solar cells, the specific operation steps are as follows:

[0040] (1) Wafer pre-cleaning: use ammonia and H 2 O 2 The mixed solution is washed for 180s at 70℃; the mass percentage of ammonia in the mixed solution is 2%, H 2 O 2 The mass percentage is 4%;

[0041] (2) Rough polishing: clean the silicon wafers cleaned in step (1) with an alkaline solution at 80°C for 60 seconds; the alkaline solution is KOH, and the mass percentage of KOH is 10%;

[0042] (3) Texturing: the silicon wafer after rough polishing in step (2) is treated with an alkali solution and alcohol additives at 70°C for 600s; the alkali solution is KOH, and the mass percentage of KOH is 5%;

[0043] (4) Smooth surface treatment: Use HF and HNO on the silicon wafer after step (3). 3 The mixed solution is treated at 5℃ for 60s; the mass percentage of HF in the mixed solution is 0.9%, HNO 3 The mass percentage is 50%;

[0044] (5) Alkaline cleaning: use ammonia w...

Embodiment 2

[0050] A method for fabricating and cleaning heterojunction solar cells, the specific operation steps are as follows:

[0051] (1) Wafer pre-cleaning: use ammonia and H 2 O 2 The mixed solution is cleaned at 80℃ for 300s; the mass percentage of ammonia in the mixed solution is 3%, H 2 O 2 The mass percentage is 6%;

[0052] (2) Rough polishing: Use an alkaline solution to clean the silicon wafer after step (1) at 90°C for 180s; NaOH solution, the mass percentage of NaOH is 13%;

[0053] (3) Texturing: the silicon wafer after rough polishing in step (2) is treated with an alkali solution and alcohol additives at 80°C for 800s; the alkali solution is a NaOH solution, and the mass percentage of NaOH is 8%;

[0054] (4) Smooth surface treatment: Use HF and HNO on the silicon wafer after step (3). 3 The mixed solution is treated at 15°C for 100s; the mass percentage of HF in the mixed solution is 1.5%, HNO 3 The mass percentage is 70%;

[0055] (5) Alkaline cleaning: use ammonia water and H ...

Embodiment 3

[0061] A method for fabricating and cleaning heterojunction solar cells, the specific operation steps are as follows:

[0062] (1) Wafer pre-cleaning: use ammonia and H 2 O 2 The mixed solution is cleaned at 80℃ for 300s; the mass percentage of ammonia in the mixed solution is 5%, H 2 O 2 The mass percentage is 7%;

[0063] (2) Rough polishing: use an alkaline solution to clean the silicon wafer after step (1) at 90°C for 180s; the alkaline solution is a KOH solution, and the mass percentage of KOH is 15%;

[0064] (3) Texturing: The silicon wafer after rough polishing in step (2) is treated with an alkaline solution and alcohol additives at 80°C for 700s; the alkaline solution is a KOH solution, and the mass percentage of KOH is 6%;

[0065] (4) Smooth surface treatment: Use HF and HNO on the silicon wafer after step (3). 3 The mixed liquor is treated at 20℃ for 180s; the mass percentage of HF in the mixed liquor is 2.0%, HNO 3 The mass percentage is 80%;

[0066] (5) Alkaline cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com