Method for testing bending fatigue resistance of 500kV windage yaw prevention jumper insulator

A fatigue test, insulator technology, applied in the direction of using a stable bending force to test the strength of materials, the test of mechanical parts, the test of machine/structural parts, etc., can solve the test of bending fatigue resistance of 500kV windproof bias jumper insulators methods and other issues to achieve the effect of ensuring stability, simple test process and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

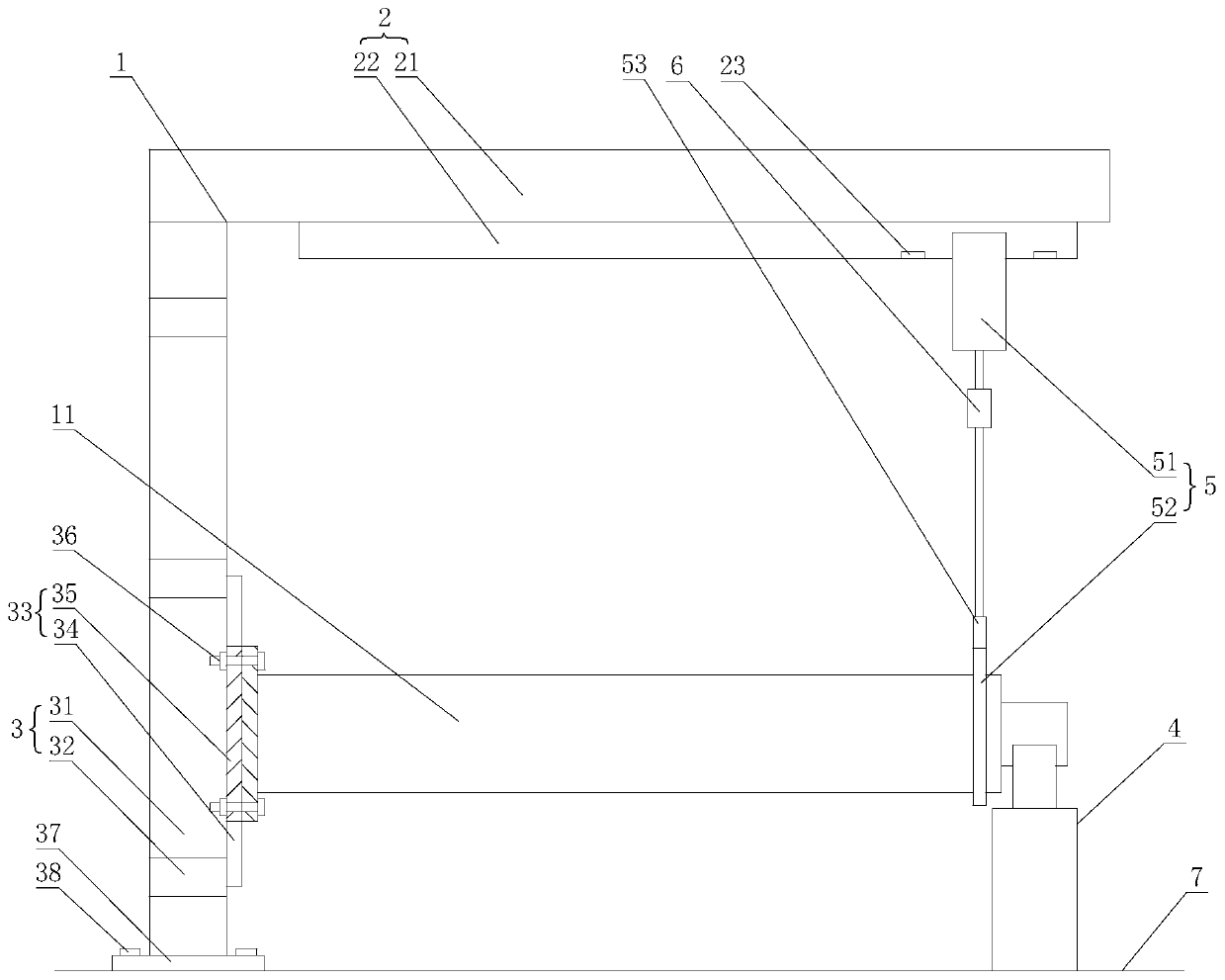

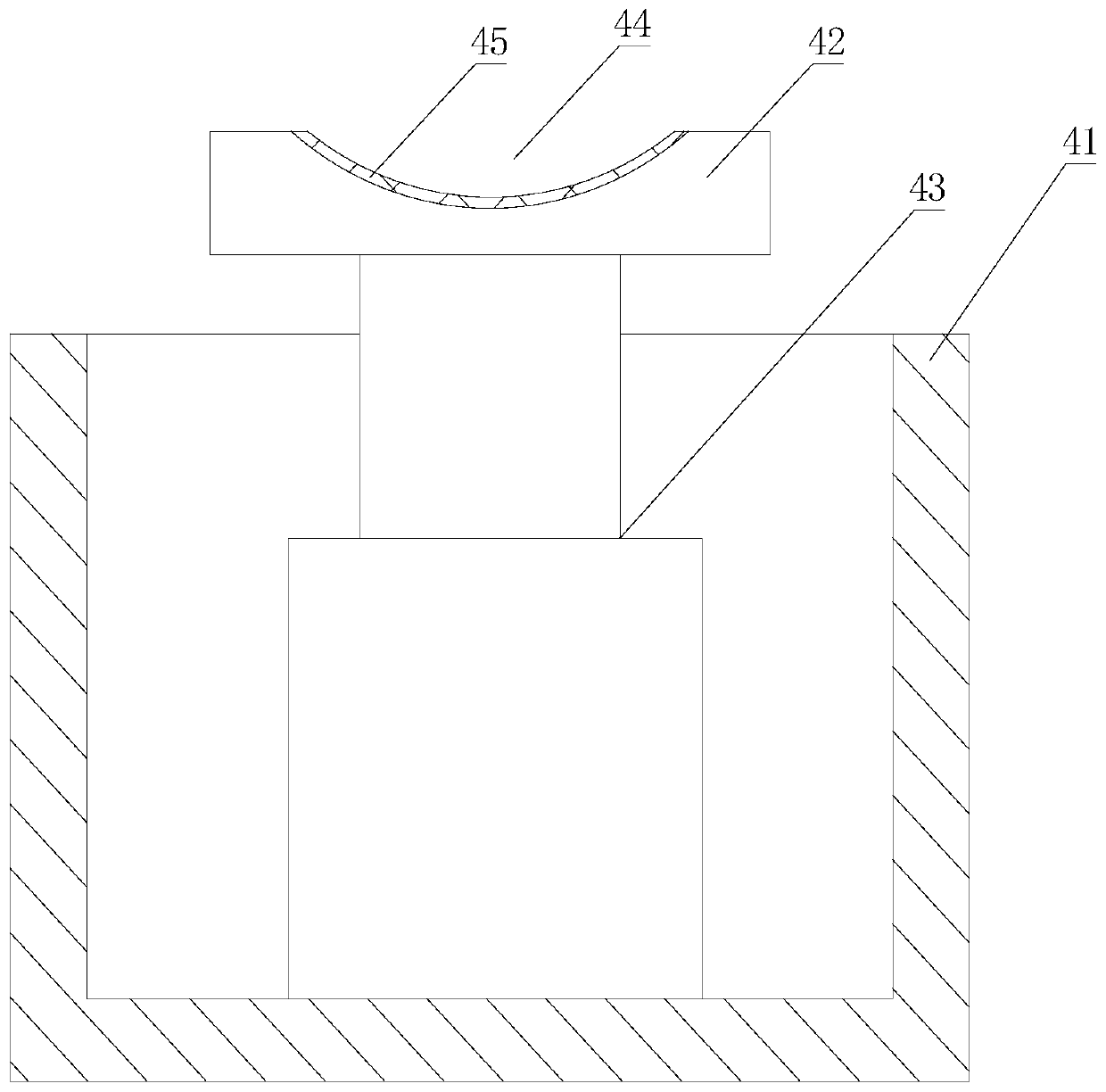

[0032] A 500kV anti-wind deflection jumper insulator anti-bending fatigue test method, the 500kV wind deflection jumper insulator includes a core body and core rods arranged at both ends of the core body, and also includes a device for installing the wind deflection jumper insulator, said The device comprises a frame 1 and a support frame 4, the frame 1 is provided with a hoisting mechanism 5, and the hoisting mechanism 5 is provided with a tension sensor 6, and the method includes the following steps in sequence:

[0033] Step 1: Fix one end of the 500kV windproof jumper insulator to the frame, then apply a rated bending load to the other end of the 500kV windproof jumper insulator, keep it for 1min, and then test the bending deflection of the 500kV windproof jumper insulator value y 1 , the rated bending load is 2.5kN;

[0034] Step 2: Install and fix the 500kV wind deflection jumper insulator after the test in step 1 on the lifting mechanism, and carry out the swing fatigu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com