Marine gas turbine inlet icing process observation test bed

A gas turbine and test bench technology, applied in the field of test benches, can solve the problems of flow field distortion, surge, and blanks at the inlet of a marine gas turbine, and achieve the effects of simple and convenient test operation, high accuracy and sufficient space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

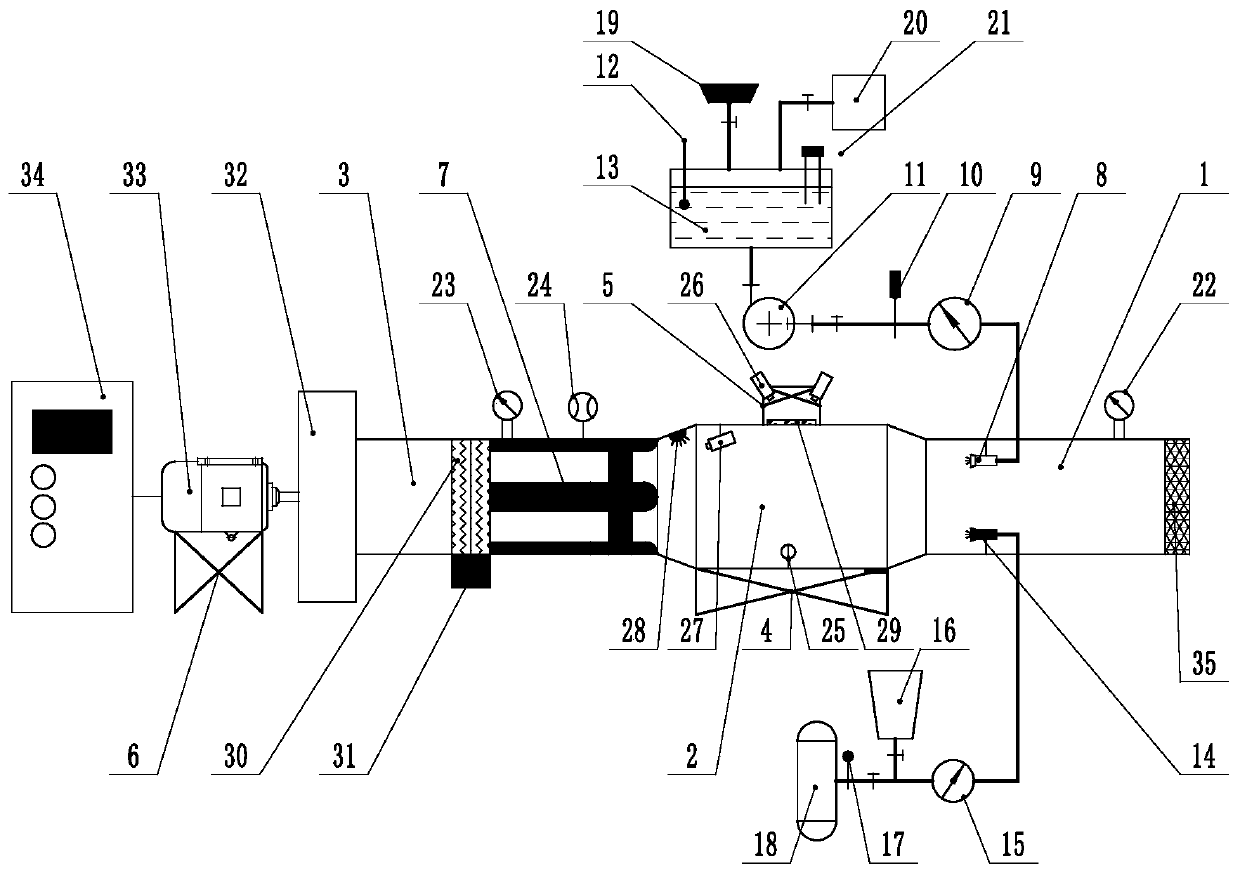

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0024] combine figure 1 , a marine gas turbine inlet icing process observation test bench of the present invention includes nine main parts of a box body, a bracket, a marine gas turbine inlet model, a spray system, a sandblasting system, a salt system, a monitoring system, a filtration collection system, and a power system.

[0025] The box includes: a box for the suction section 1, a box for the mixing section 2, and a box for the test section 3.

[0026] The bracket includes: a cabinet bracket 4, a phase Doppler particle analyzer bracket 5, and a motor bracket 6.

[0027] Import models of marine gas turbines include: scaled-down models of different types of marine gas turbine imports7.

[0028] The spraying system includes: liquid nozzle 8 , water pressure gauge 9 , liquid flow meter 10 , water pump 11 , thermometer 12 , and water tank 13 .

[0029] The sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com