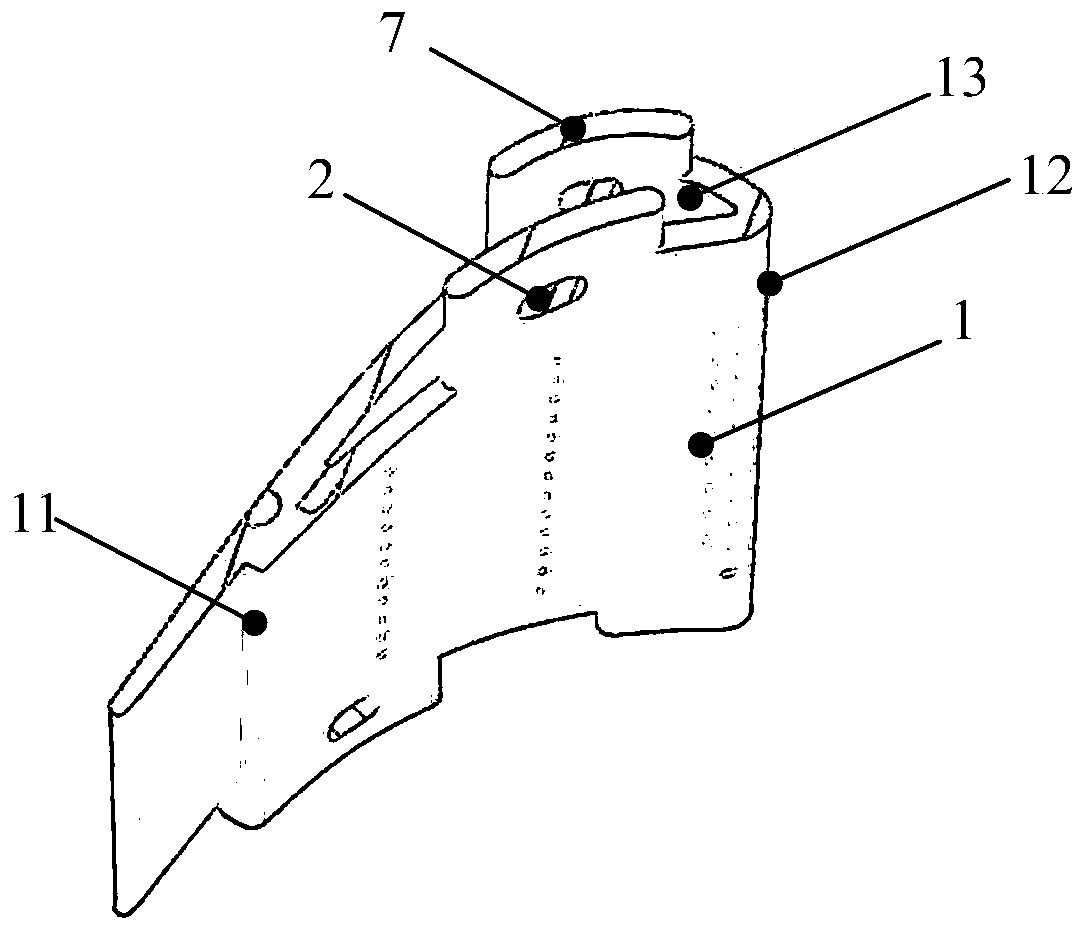

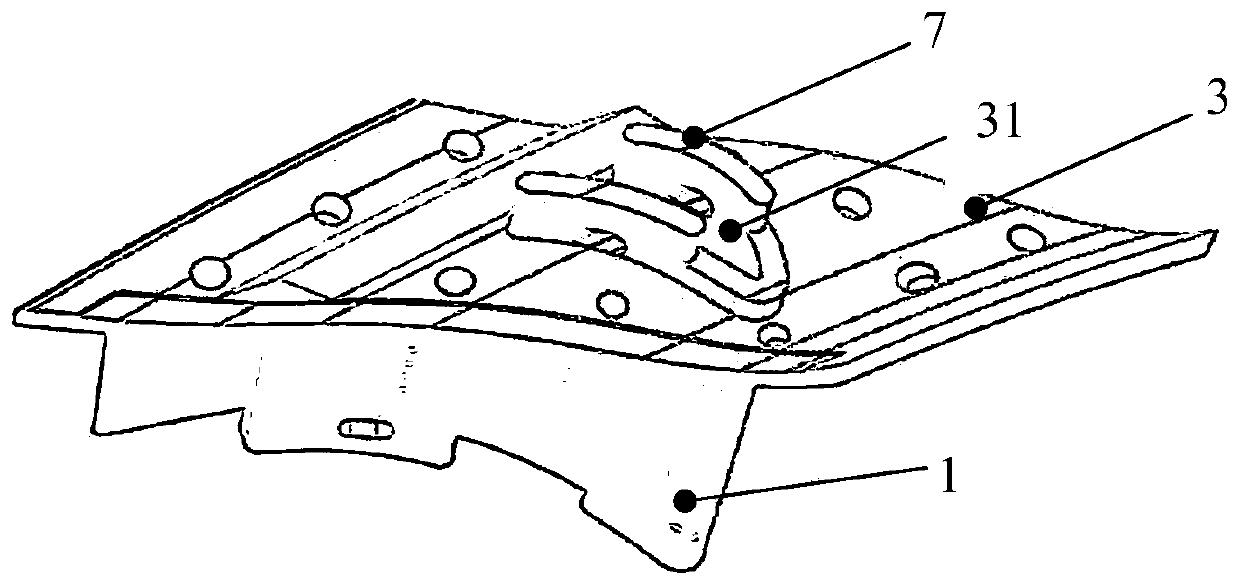

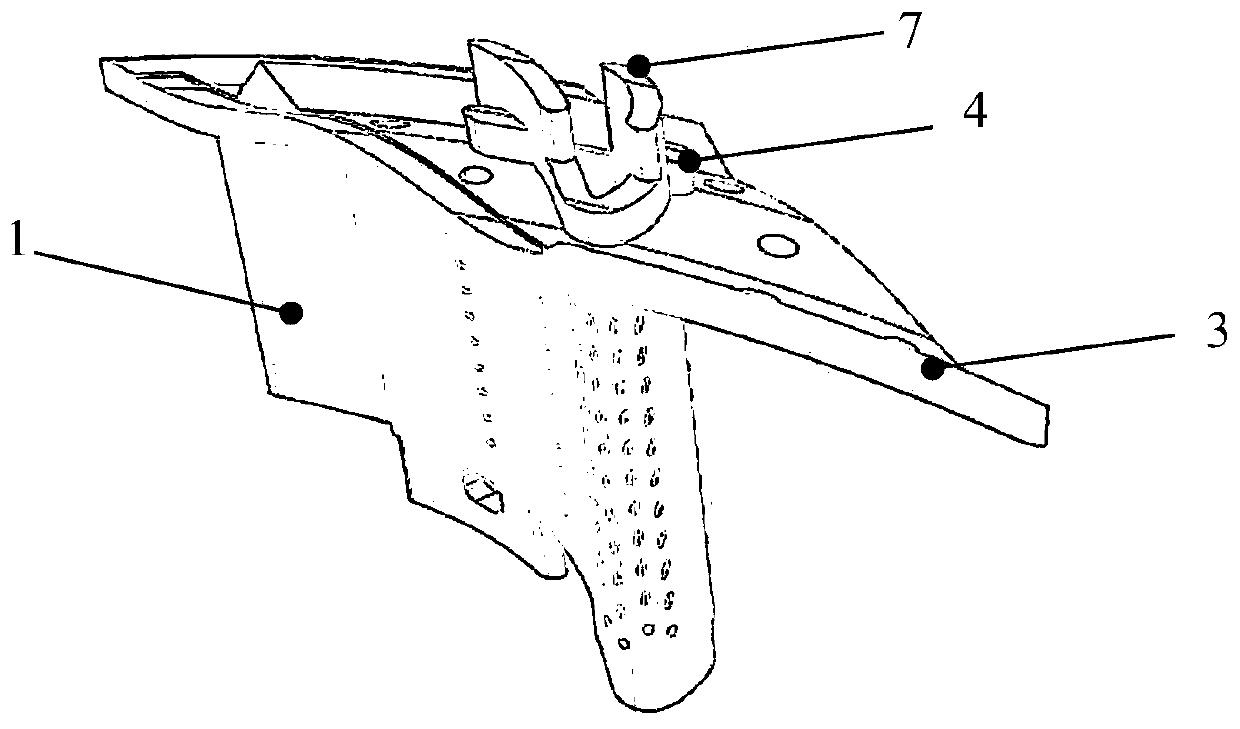

Ceramic matrix composite material fixing guider blade structure of aircraft engine and molding thereof

A technology of aero-engine and composite materials, which is applied to engine components, machines/engines, stators, etc., can solve the problems of unreasonable design of CMC guide vane prefabricated body, poor blade root strength, etc. Process adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The size of the CMC fixed guide vane in this embodiment: length 60mm, width 50mm, height 120mm. The raw material of the ceramic matrix composite material in this embodiment is SiC fiber, and the raw material used in the preparation process is trichloromethylsilane and H 2 , Ar gas, etc.

[0056] Specific steps are as follows:

[0057] (1) Preparation of prefabricated body: SiC fiber is used to weave 2D plain weave cloth, and other prefabricated body types such as 2.5D and 3D can also be used. Cut the plain weave into an appropriate size according to the size of the part, stack multiple layers of plain weave, and puncture in the stacking direction of the plain weave. The punctured fiber uses the same SiC fiber to form a SiC fiber prefabricated body. The SiC fiber preform is fixed and molded by using a mold.

[0058] (2) Interface layer preparation: the prefabricated body in step (1) is placed in a chemical vapor deposition furnace to prepare an interface layer. The b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com