A grouting reinforcement method for fault fracture zone in coal mining face

A coal mining face, grouting reinforcement technology, applied in mining equipment, earthwork drilling, wellbore lining, etc., can solve the problem of coal and rock mass fragmentation, fault fracture zone treatment methods are difficult to effectively support, fault fracture zone coal rock Problems such as damage to the integrity of the body, to achieve the effect of guaranteeing the effect of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

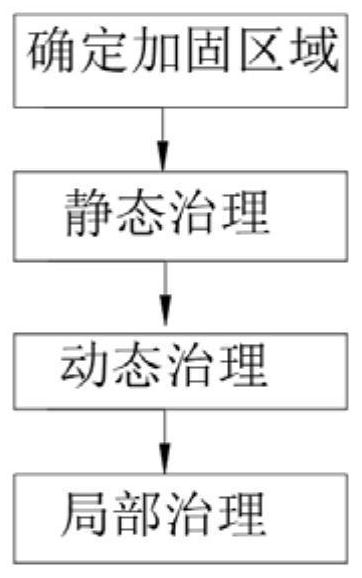

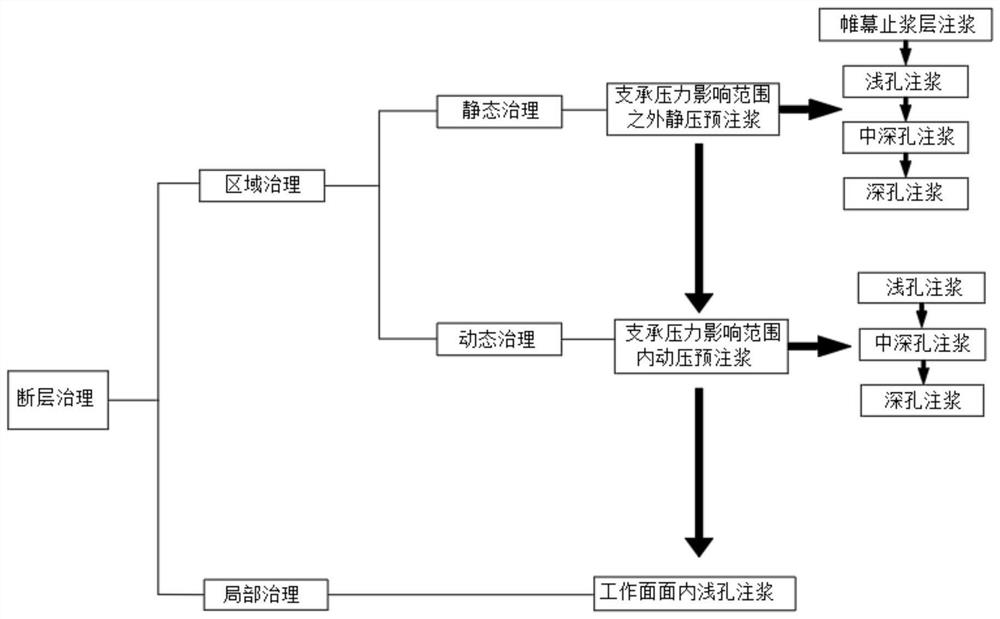

Method used

Image

Examples

Embodiment 1

[0044] In this example, the mining of a coal mining face of a certain mine is taken as the engineering background. The coal seam of the a working face is: b coal, black, powdery, containing a small amount of block and thin slices, and the macroscopic coal rock type is semi-dark-semi Bright briquette, the macroscopic feature is that the coal seam is soft and brittle, broken into fragments and powder, the b coal seam has an average inclination angle of 6°-8°, and is partially affected by geological structures such as faults, and the occurrence and thickness of the b coal seam have certain changes. The average thickness of b coal seam is 3.4m, which belongs to relatively stable coal seam.

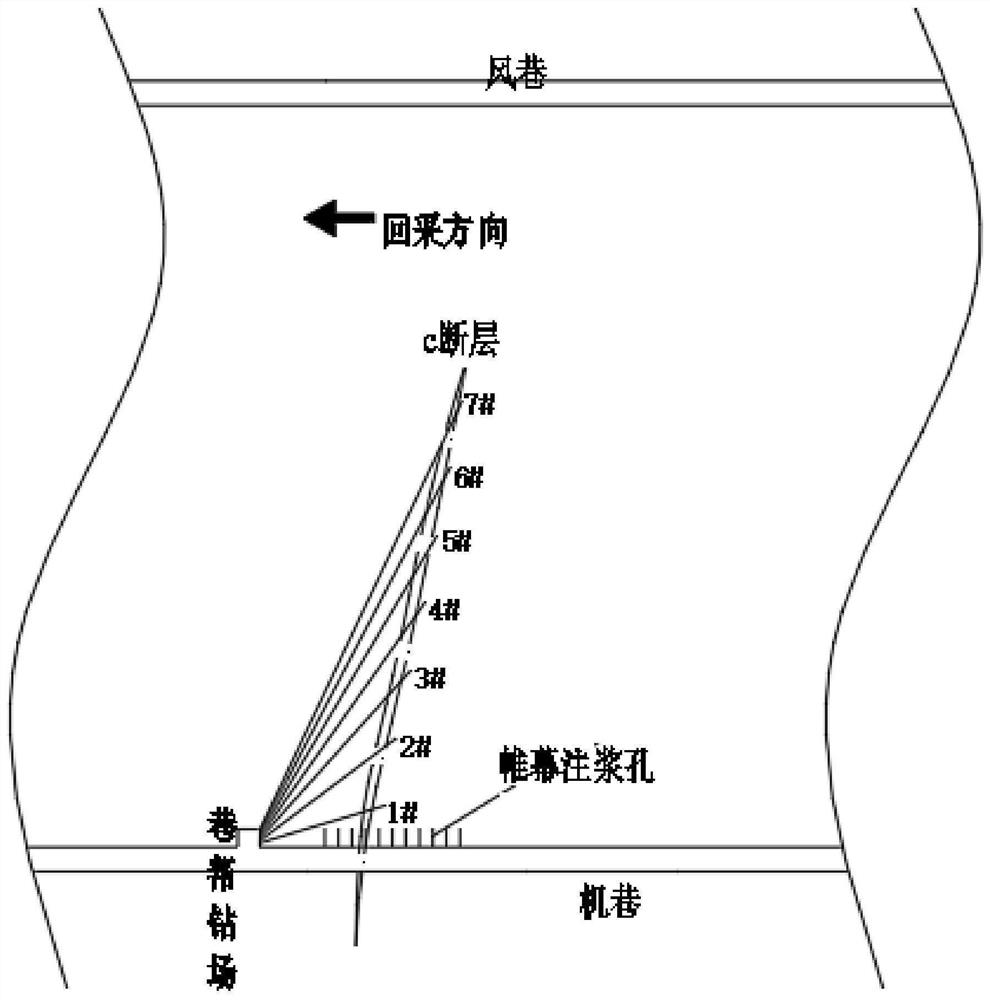

[0045] Such as image 3 As shown, fault c develops at an average distance of 290m from the cutting eye in the working face a. The nature of the fault is a reverse fault, with a strike of 187°, a dip of 98°, a dip of 86°, and a drop of 5.2m. The mining safety of the working face has a greater ...

Embodiment 2

[0064]In this embodiment, the mining of working face d of a mine is taken as the engineering background, and the coal seam condition of working face d is: f coal, black, powdery, bright coal, vitreous luster, soft in nature, and local inclusions with an average thickness of 0.5-0.8m Gangue (mudstone), the average thickness of the coal seam is 4.5m, and the average inclination angle is 8-10°, which belongs to the stable coal seam. The working face d dips with an average length of 149m, and e-fault develops at a position 142m away from the cutting eye. The e fault has an influence of 30m on the strike and 130m on the inclination, which has a great influence on the safe mining of the working face, such as Image 6 shown.

[0065] The method of parallel hole arrangement in the air lane is adopted to carry out static pressure pre-grouting outside the range of the advanced bearing pressure. First, the grouting of the curtain grouting layer is carried out within the influence range...

Embodiment 3

[0076] In this embodiment, when the coal mining face is mined within the influence range of the advanced abutment pressure, dynamic treatment is carried out on the basis of the static treatment in Example 1, and the dynamic treatment is flexibly supplemented according to the effect of the static treatment. When there is a large deviation between the static treatment effect and the expected effect, if necessary, use dynamic treatment, that is, one or more of the three grouting processes of shallow hole grouting, medium-deep hole grouting, and deep hole grouting. The fault fracture zone is strengthened by grouting, and the design principle of shallow hole, medium deep hole and deep hole drilling parameters is the same as that of embodiment 1; if there is no deviation or unnecessary, dynamic treatment on the basis of static treatment is not necessary.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com