Pure liquid flow negative pressure drainage system

A technology of liquid phase flow and negative pressure, which is applied in the direction of waterway system, sewer pipeline system, sewage discharge, etc., and can solve the problems of large pipeline resistance loss and frequent start-up of vacuum pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

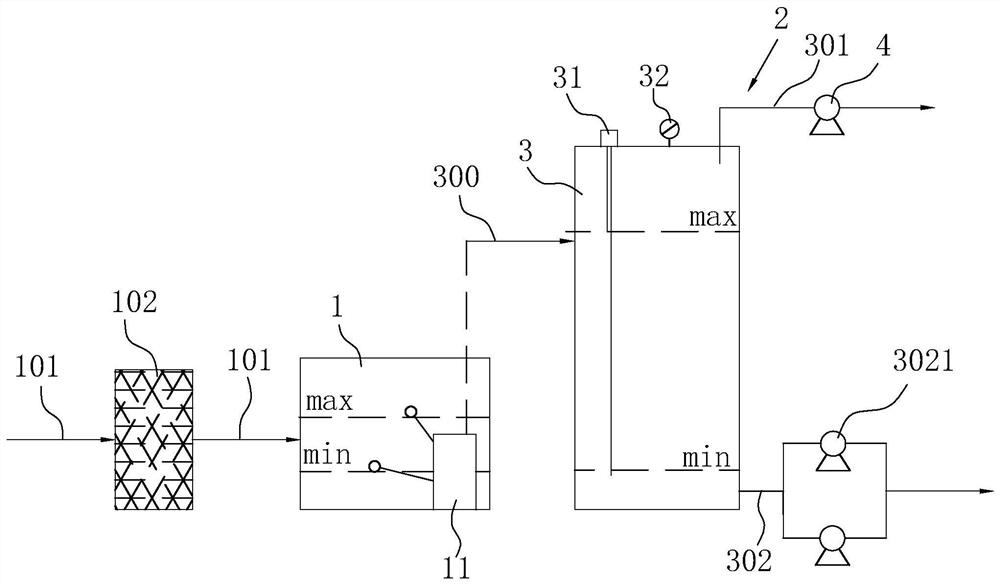

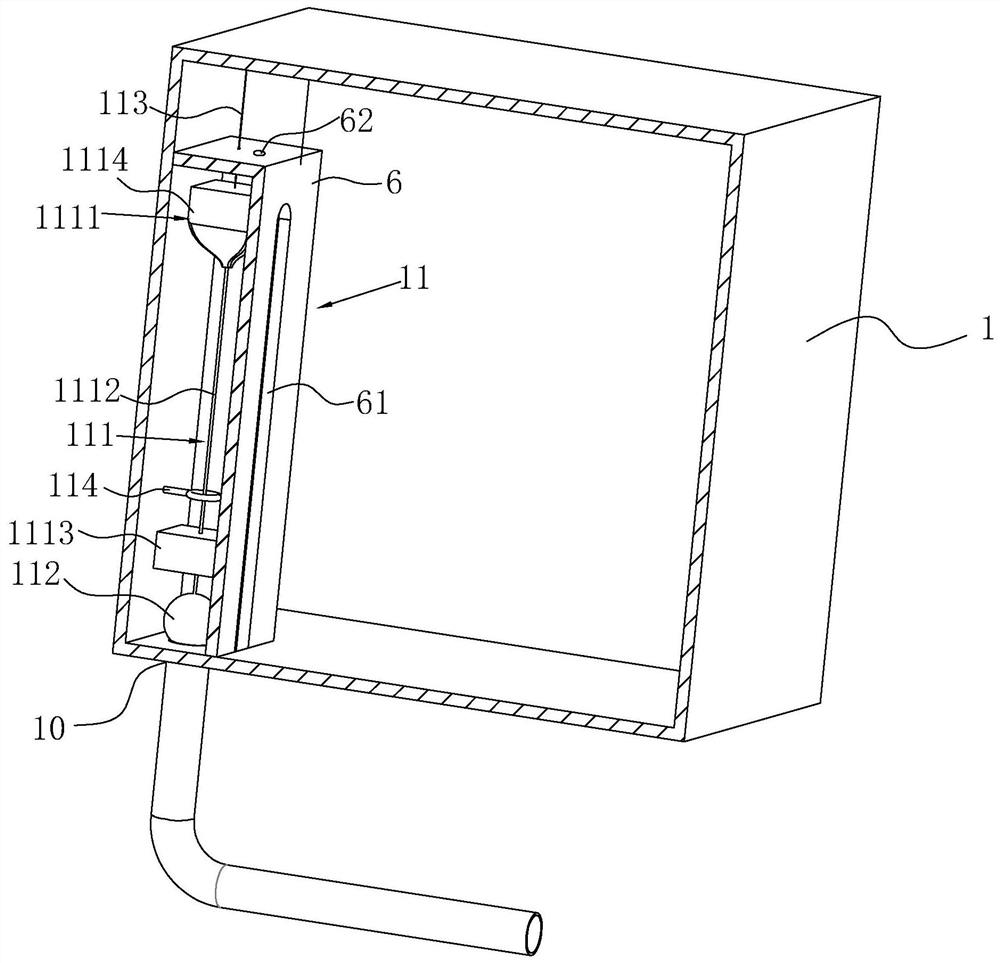

[0057] The invention discloses a pure liquid phase flow negative pressure drainage system, which is suitable for the collection and treatment of urban and rural domestic sewage, such as figure 1 As shown, it includes multi-point distributed negative pressure fluid collection wells 1 and a vacuum station 2 connected to the negative pressure fluid collection wells 1 through a negative pressure delivery pipeline 300 . Negative pressure fluid collection wells 1 are respectively buried under the ground of single-family residences in cities and towns or rural areas. Negative pressure fluid collection wells 1 are connected to user septic tanks through sewage confluence pipeline 101; The pipeline opening and closing control device 11 for well 1 and vacuum station 2 on-off; The upper part of the tank 3 is connected, and the negative pressure fluid collection tank 3 communicates with the vacuum pump 4 through the gas delivery pipe 301 at its top. Through the fluid pipe 302 to the targe...

Embodiment 2

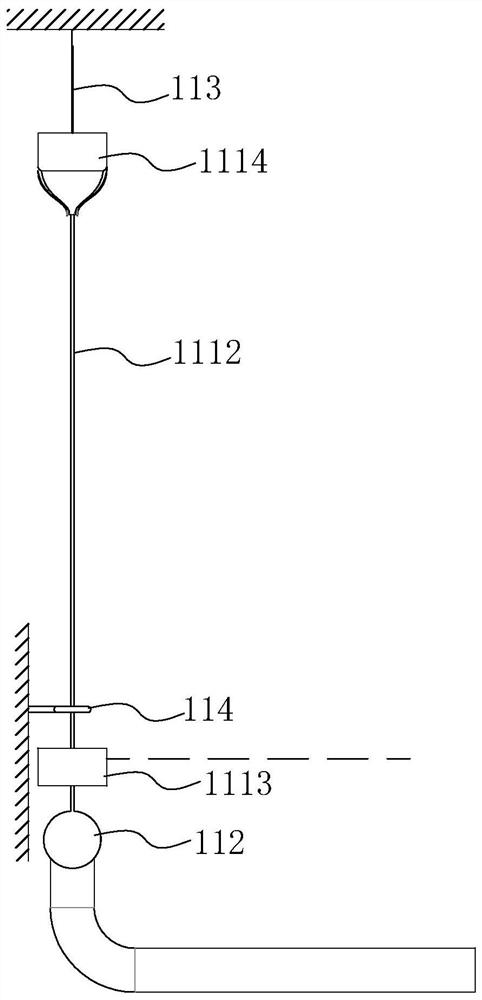

[0071] Embodiment 2 of the present invention has the same structure as Embodiment 1, but when applying the negative pressure pipeline opening and closing device provided by the present invention, it is necessary to determine the volume and weight of the floating block 1111 used according to the density of the liquid to ensure that the first floating block 1113 The buoyancy ρ received by the buoyant member 111 when it is completely submerged under the liquid surface and the liquid surface does not reach the second floating block 1114 液 wxya 下max greater than the total gravity of the buoyant element 111 and the blocking element 112 and equal to the sum of the total gravity of the buoyant element 111 and the blocking element 112 and the negative pressure suction, while ensuring that the buoyant element 111 is under pressure when the entire buoyant element 111 is completely submerged under the liquid surface buoyancy ρ 液 wxya max It is greater than the sum of the total gravity a...

Embodiment 3

[0074] Embodiment 2 of the present invention has the same structure as Embodiment 1, but when applying the negative pressure pipeline opening and closing device provided by the present invention, it is necessary to determine the volume and weight of the floating block 1111 used according to the density of the liquid to ensure that the first floating block 1113 The buoyancy ρ received by the buoyant member 111 when it is completely submerged under the liquid surface and the liquid surface does not reach the second floating block 1114 液 wxya 下max greater than the total gravity of the buoyant element 111 and the blocking element 112 and less than the sum of the total gravity of the buoyant element 111 and the blocking element 112 and the negative pressure suction, while ensuring that the buoyant element 111 is under pressure when the second floating block 1114 is partially submerged under the liquid surface buoyancy ρ 液 gV is greater than the sum of the total gravity and negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com