Saw-chip kitchen waste processor

A kitchen waste and processor technology, which is applied to indoor sanitary pipe installations, water supply installations, buildings, etc., can solve the problems of poor shearing effect, unfavorable product promotion, and high cost of ring gear, so as to improve the crushing effect and reduce the Production cost and effect of improving discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

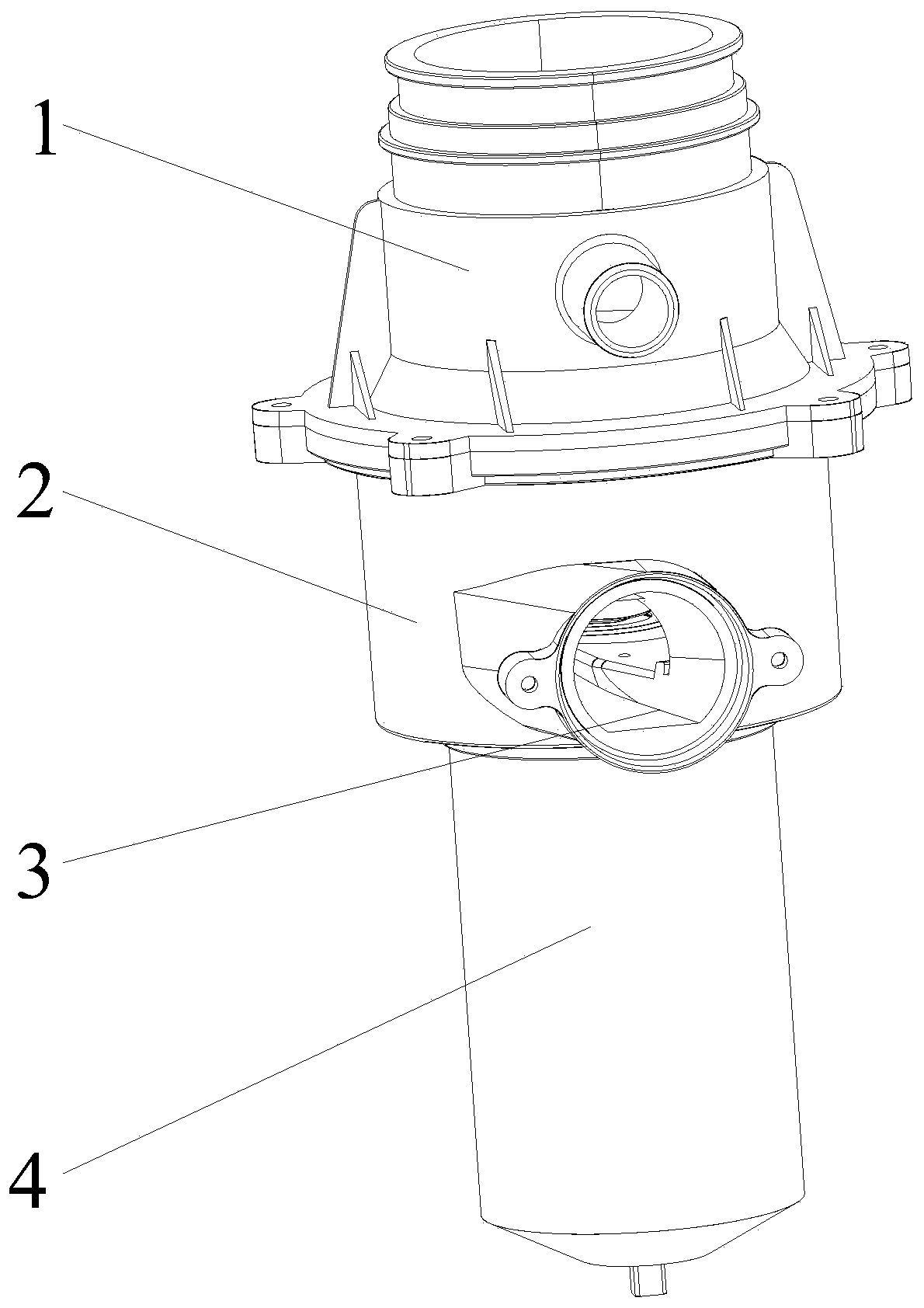

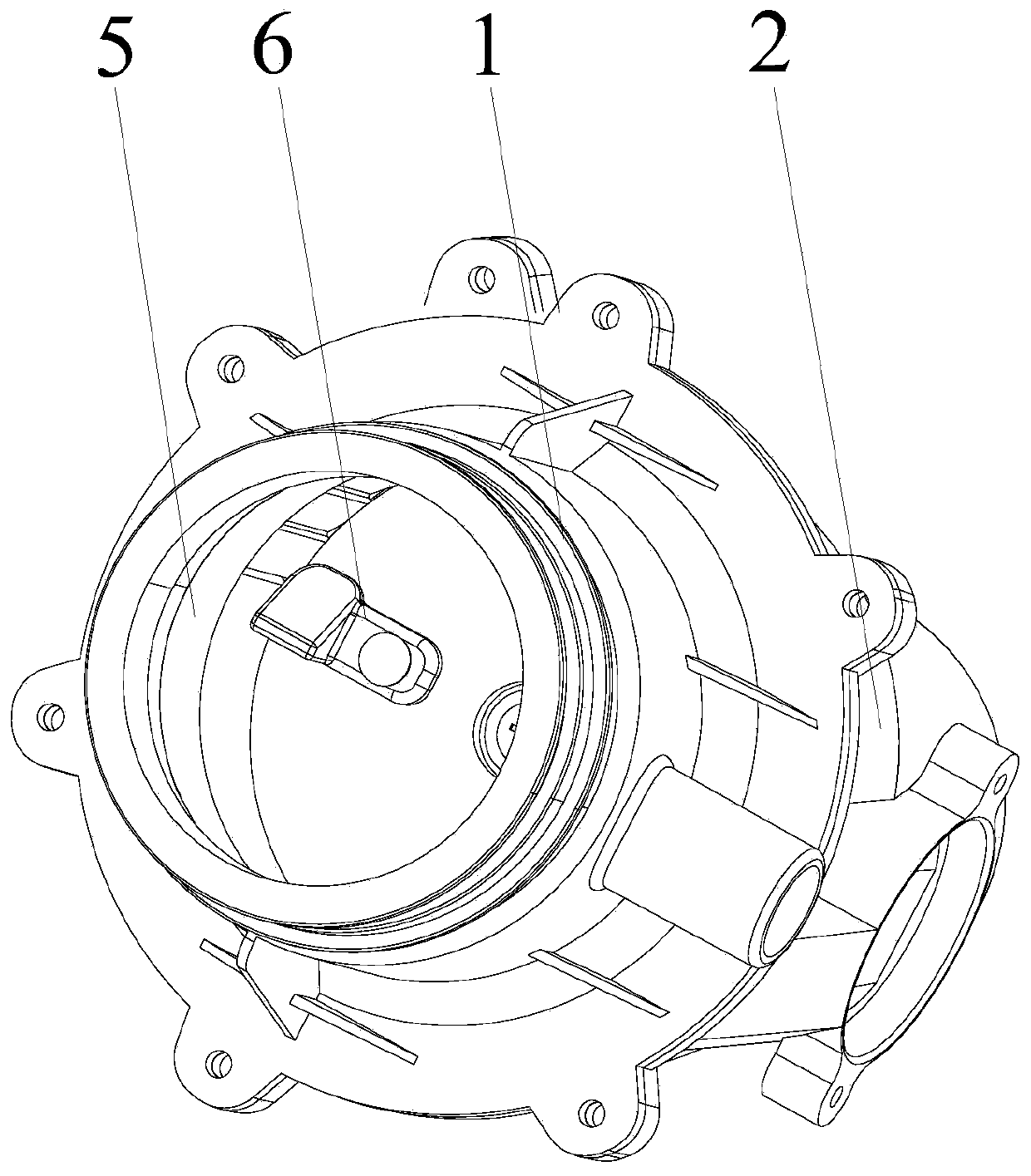

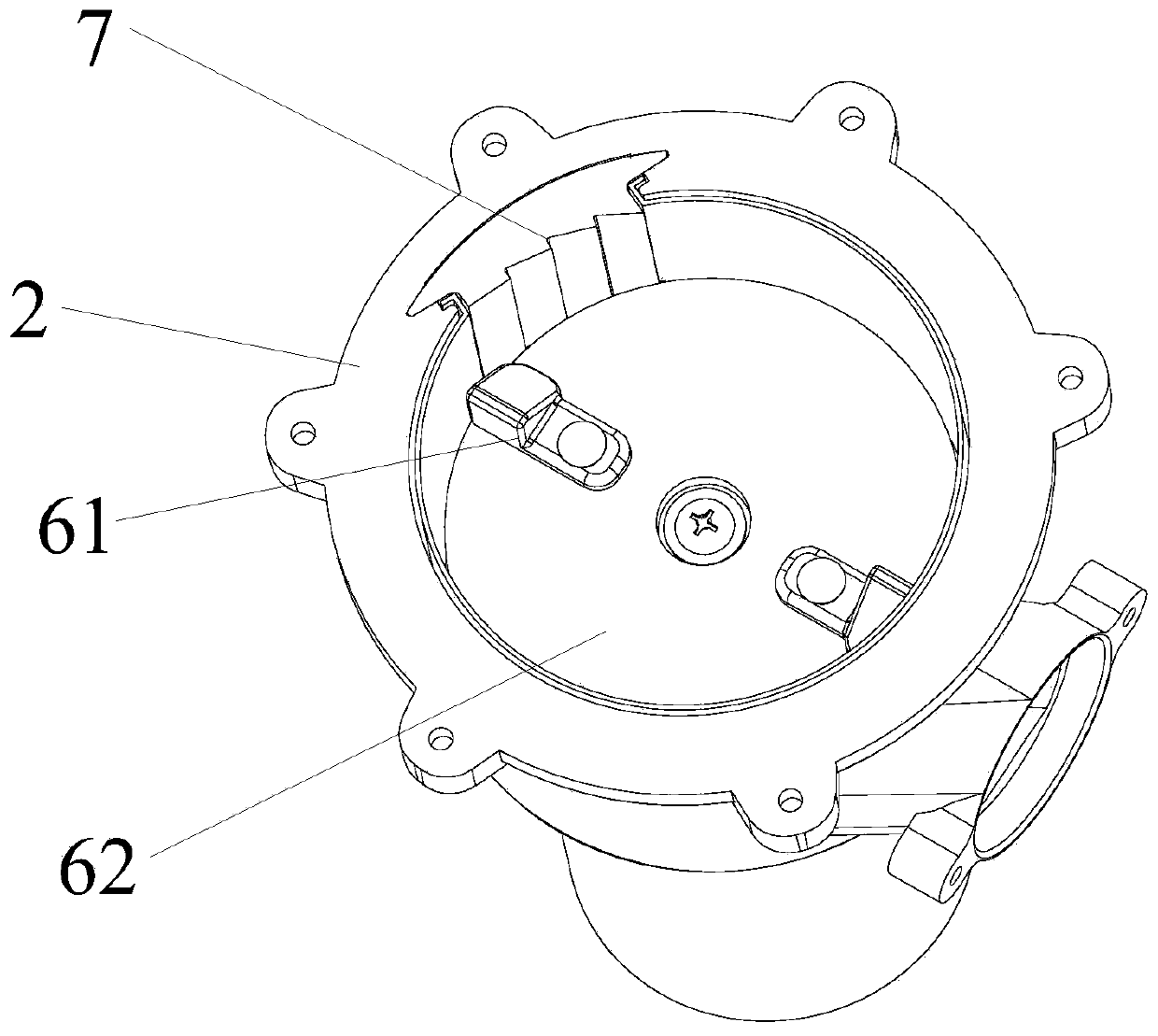

[0033] Such as Figure 1 to Figure 9 As shown, a sawn type kitchen waste disposer provided by the present invention includes a material barrel 1 and a pump casing 2. After the material barrel 1 and the pump casing 2 are assembled, a processing chamber 5 is formed inside, and the processing chamber 5 is provided with The flywheel assembly 6 and the sawtooth block 7, the flywheel assembly 6 is used to drive the rotation of the kitchen waste in the processing chamber 5, the sawtooth block 7 is used to saw the kitchen waste in the rotating state, and the sawtooth block 7 includes several saw blades The units 71 are stacked.

[0034] Wherein, the barrel 1 and the pump casing 2 are combined and assembled, and the barrel 1 and the pump casing 2 are fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com