Friction-spun phase-change antistatic composite yarn and preparation method thereof

A composite yarn, antistatic technology, applied in the direction of yarn, textiles, papermaking, fiber types, etc., can solve the problems of imperfect preparation technology, poor thermal conductivity of core-spun yarn, and difficulty in large-scale promotion, etc., to achieve heat storage Good effect, increased durability, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] like figure 1 Shown, a kind of friction spinning phase change antistatic composite yarn and preparation method thereof, its steps are as follows:

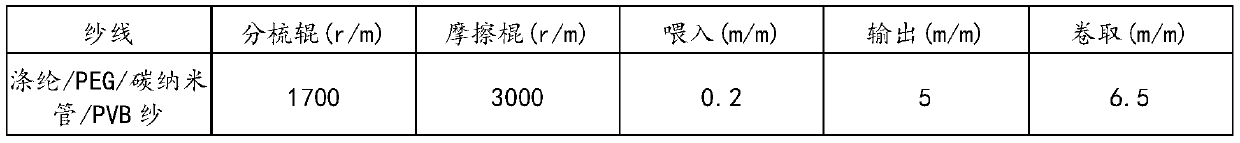

[0023] 1) The 18tex polyester yarn passes through the PEG and carbon nanotube mixture storage tank and the PVB solution storage tank on the sizing machine in turn to complete the PEG impregnation and PVB impregnation of the polyester yarn to obtain polyester / PEG / carbon nanotube / PVB yarn. The molecular weight of PEG is 2000, and the temperature of the storage tank is set at 70°C. The temperature of the PVB ethanol solution storage tank is normal temperature, and the solution concentration is 10%. After the PEG is completely melted, add the carbon nanotube dispersion, the content of the carbon nanotube is 1% of the PEG mass, and then import the polyester yarn at a speed of 8m / min, and then pass through the PEG and carbon nanotube mixture storage tank and PVB solution for storage After the groove, the polyester / PEG2000 / carbon...

Embodiment 2

[0029] like figure 1 Shown, a kind of friction spinning phase change antistatic composite yarn and preparation method thereof, its steps are as follows:

[0030] 1) The 24tex polyester yarn passes through the PEG and carbon nanotube mixture storage tank and the PVB solution storage tank on the sizing machine in turn to complete the PEG impregnation and PVB impregnation of the polyester yarn to obtain polyester / PEG / carbon nanotube / PVB yarn. The molecular weight of PEG is 4000, and the temperature of the storage tank is set at 75°C. The temperature of the PVB ethanol solution storage tank is normal temperature, and the solution concentration is 30%. After the PEG is completely melted, add the carbon nanotube dispersion, the content of the carbon nanotube is 2% of the PEG mass, and then import the polyester yarn at a speed of 6m / min, and then pass through the PEG and carbon nanotube mixture storage tank and PVB solution for storage After the groove, the polyester / PEG4000 / carbon...

Embodiment 3

[0036] like figure 1 Shown, a kind of friction spinning phase change antistatic composite yarn and preparation method thereof, its steps are as follows:

[0037] 1) The 32tex polyester yarn passes through the PEG and carbon nanotube mixture storage tank and the PVB solution storage tank on the sizing machine in turn to complete the PEG impregnation and PVB impregnation of the polyester yarn to obtain polyester / PEG / carbon nanotube / PVB yarn. The molecular weight of PEG is 8000, and the temperature of the storage tank is set at 80°C. The temperature of the PVB ethanol solution storage tank is normal temperature, and the solution concentration is 20%. After the PEG is completely melted, add the carbon nanotube dispersion, the content of the carbon nanotube is 3% of the PEG mass, and then import the polyester yarn at a speed of 7m / min, and then pass through the PEG and carbon nanotube mixture storage tank and PVB solution for storage After the groove, the polyester / PEG8000 / carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com