A ceramic point source for evaporation equipment

A ceramic and point source technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve problems affecting the temperature control of the crucible, and achieve stable heat conduction loss, precise and uniform temperature control, and high heating speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

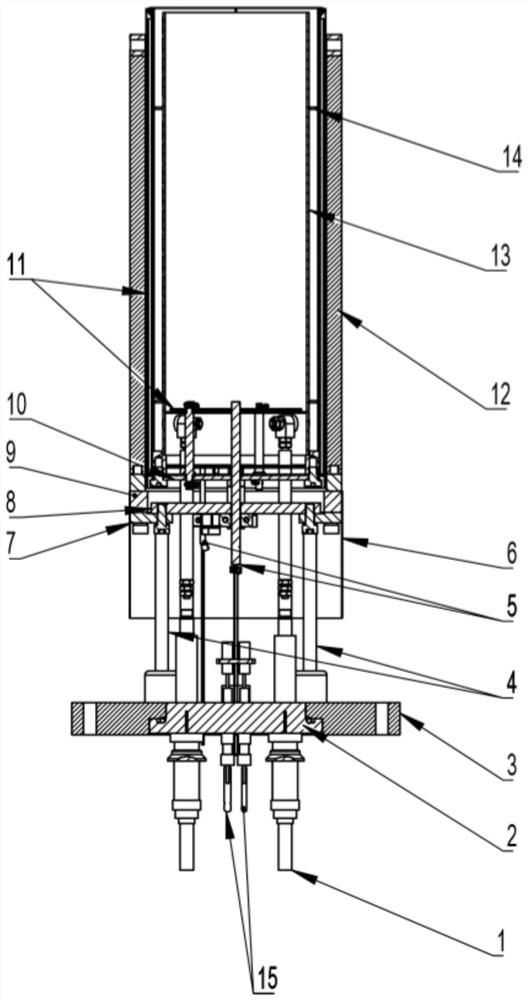

[0051] A ceramic point source for uniform heating on evaporation equipment, including a connecting flange 3, an electrode-thermocouple connection base 2, a cooling water jacket 12, a heat preservation component, a heating component, and an evaporation chamber; figure 1 shown.

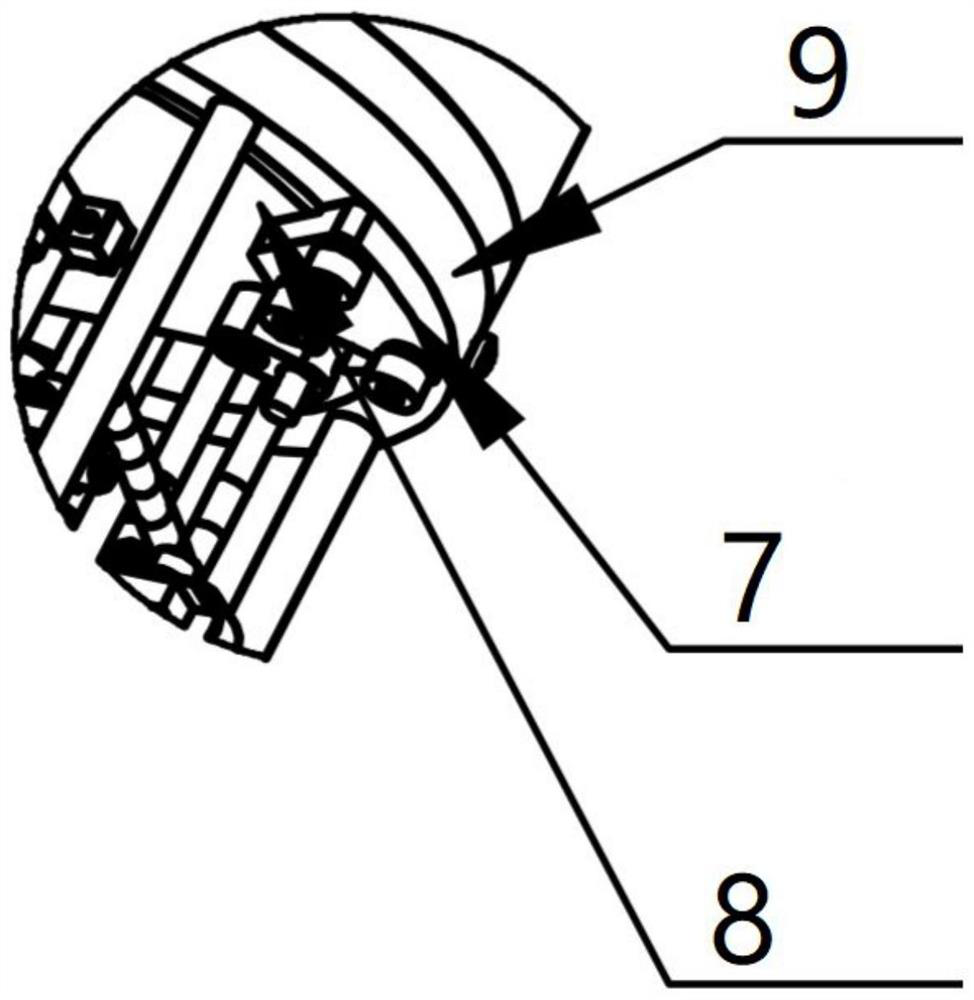

[0052] The connection flange 3 is connected with the electrode-thermocouple connection base 2, and the connection flange is used to connect and fix the ceramic point source to the external equipment. The electrode-thermocouple connection base is provided with an external electrode 1 and a vacuum thermocouple joint 15. The flange 3 is provided with a cooling water pipe 4, one end of the cooling water pipe 4 is connected to the connecting bottom ring 9, and the upper side of the connecting bottom ring 9 is provided with a cooling water jacket 12, and the cooling liquid in the cooling water pipe enters the cooling water jacket through the connecting bottom ring 9 Circulating cooling is carried out to achie...

Embodiment 2

[0056] A ceramic point source used for uniform heating on evaporation equipment, its structure is as described in Embodiment 1, the difference is that the heat preservation component includes a metal heat preservation cylinder 23, and the metal heat preservation cylinder includes two nested shells 23- 1 and the bottom surface, a cylindrical insulation board is arranged between the two shells.

[0057] The bottom surface of the metal insulation cylinder is connected with a base plate 10, and the large supporting plate is provided with support columns, which are used to provide support for the base plate. The two shells and the bottom surface of the metal insulation cylinder are welded together, the bottom surface is thinner, and the bottom plate is added to provide stronger support.

Embodiment 3

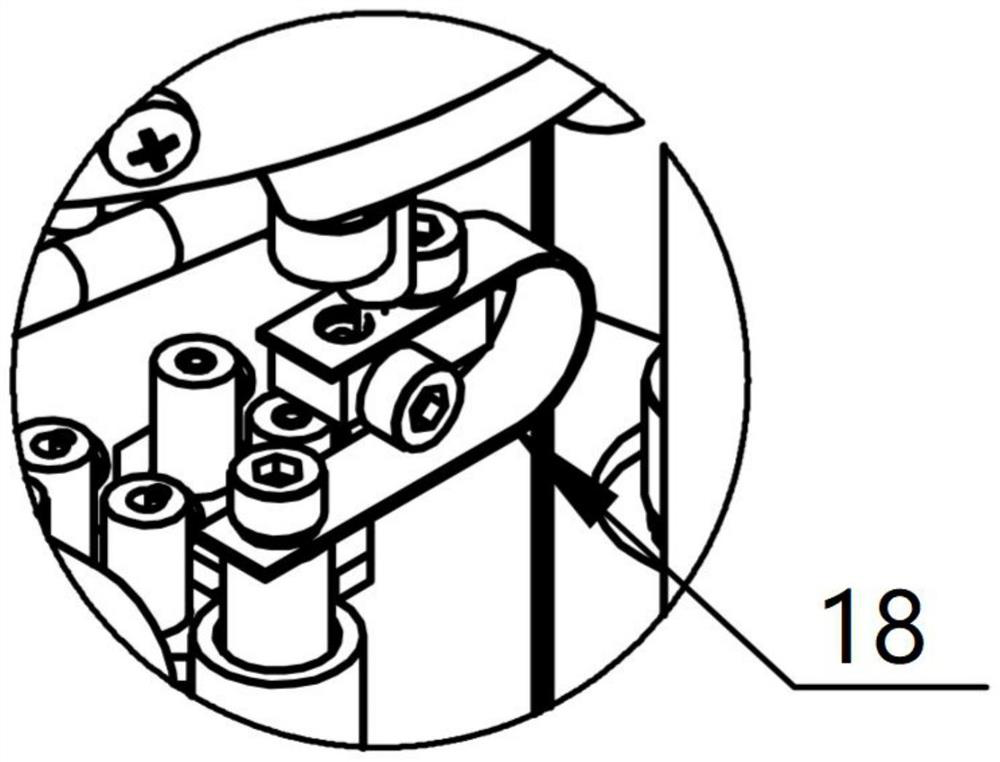

[0059] A ceramic point source for uniform heating on evaporation equipment, its structure is as described in Embodiment 2, the difference is that the heater is a pyrolytic boron nitride-pyrolytic graphite heater, and the heater includes a substrate, a device The circuit layer on the substrate, the insulating layer, and the circuit connector, the circuit connector is connected to the electrode of the heater, and the heater is heated by an external power supply, and the heating component also includes a bottom connection ring 21, which is located above the bottom plate 10, such as Figure 5 Shown, the bottom attachment ring is used to support the heater.

[0060] The support column runs through the bottom plate, and the support column is threadedly connected with the bottom connecting ring. The support column fixes between the large supporting plate, the base plate and the bottom connecting ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com