Foam-type cobalt/carbon composite wave-absorbing material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

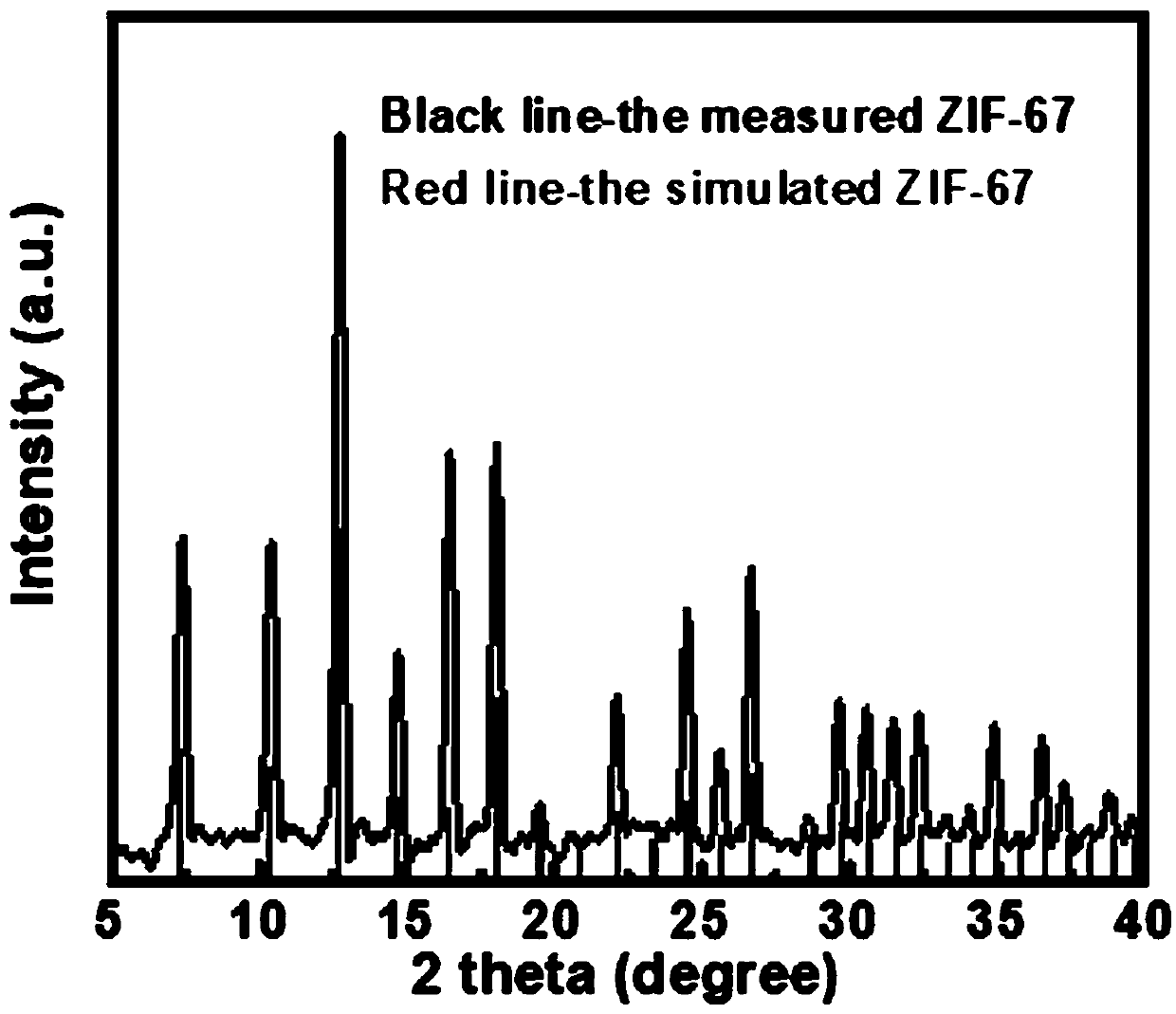

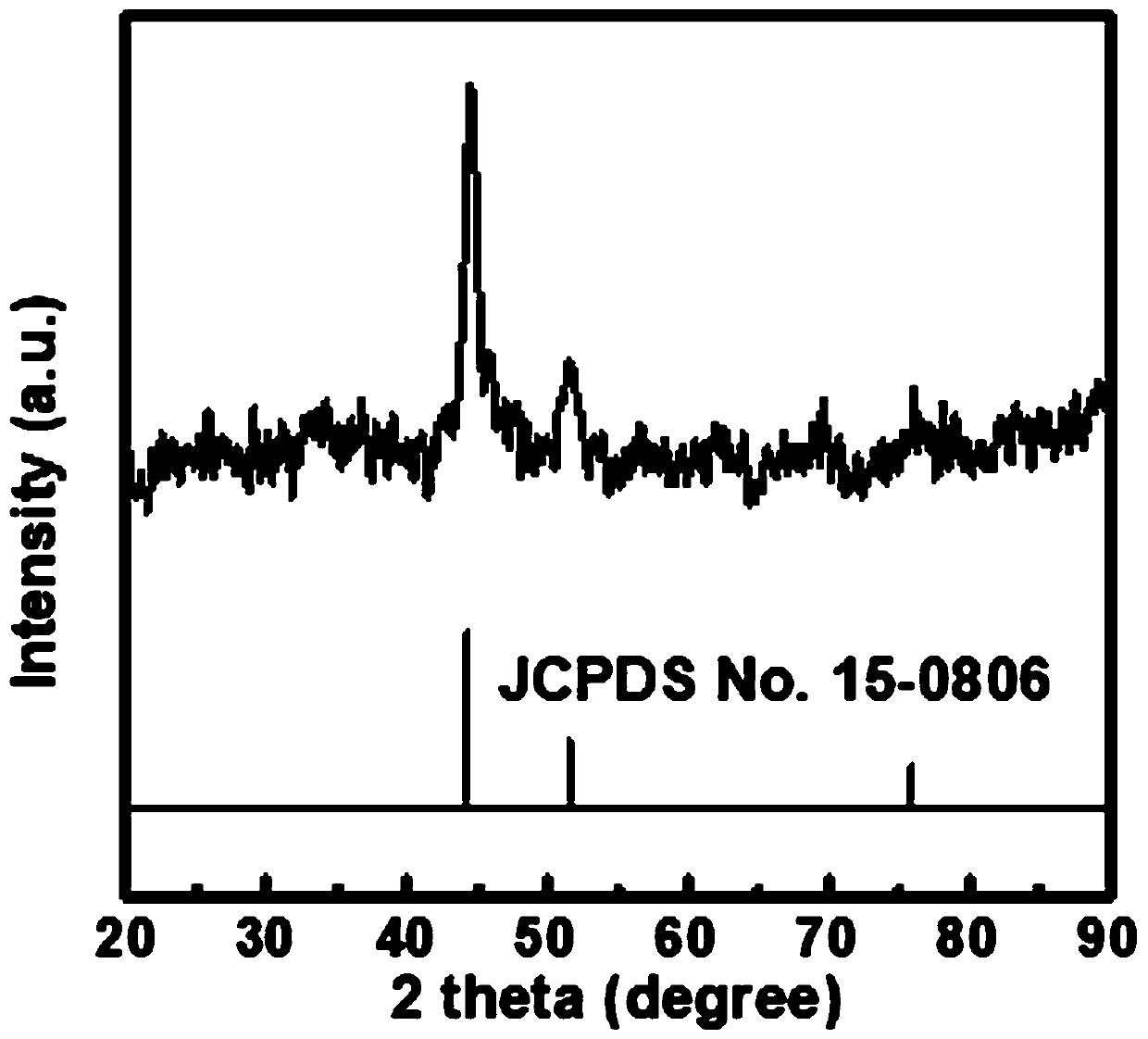

Image

Examples

Embodiment 1

[0033] A preparation method of a foam-type cobalt / carbon composite absorbing material in this embodiment is carried out according to the following steps:

[0034] 1. Preparation of PS microspheres: Take 100 mL of styrene dispersion with a concentration of 0.3 g / L and wash with deionized water and sodium hydroxide solution to remove the stabilizer in the styrene raw material, and dissolve the washed styrene in 500 mL of deionized water, and 2 g of polyvinylpyrrolidone powder were added and stirred evenly, the mixed solution was passed through nitrogen for 15 min, and then 1 g of K 2 S 2 o 8 To initiate styrene polymerization; the mixed solution was stirred at a stirring speed of 300 rpm for 24 h to obtain a milky monodisperse polystyrene sol;

[0035] 2. Preparation of three-dimensional ordered PS templates: Three-dimensional ordered PS templates were obtained by suction filtration; the polystyrene sol was poured into a suction filtration device with double-layer filter pape...

Embodiment 2

[0045] A preparation method of a foam-type cobalt / carbon composite absorbing material in this embodiment is carried out according to the following steps:

[0046] 1. Preparation of PS microspheres: Take 50 mL of styrene dispersion with a concentration of 0.3 g / L and wash with deionized water and sodium hydroxide solution to remove the stabilizer in the styrene raw material, and dissolve the washed styrene in 100 mL of deionized water, and add 8 g of sodium dodecylbenzenesulfonate powder and stir evenly, the mixed solution is passed through nitrogen for 5 min, and then 5 g of K 2 S 2 o 8 To initiate styrene polymerization; the mixed solution was stirred at a stirring speed of 100 rpm for 24 h to obtain a milky monodisperse polystyrene sol;

[0047] 2. Preparation of three-dimensional ordered PS templates: Three-dimensional ordered PS templates were obtained by suction filtration; the polystyrene sol was poured into a suction filtration device with double-layer filter paper, ...

Embodiment 3

[0053] A preparation method of a foam-type cobalt / carbon composite absorbing material in this embodiment is carried out according to the following steps:

[0054] 1. Preparation of PS microspheres: Take 150 mL of styrene dispersion with a concentration of 0.3 g / L and wash it with deionized water and sodium hydroxide solution to remove the stabilizer in the styrene raw material, and dissolve the washed styrene in 400 mL of deionized water, and add 6g of triethanolamine and polyvinylpyrrolidone mixture and stir evenly, the mixed solution is passed nitrogen gas for 5 min, then add 4 gK 2 S 2 o 8 To initiate styrene polymerization; the mixed solution was stirred at a stirring speed of 200 rpm for 24 h to obtain a milky monodisperse polystyrene sol;

[0055] 2. Preparation of three-dimensional ordered PS templates: Three-dimensional ordered PS templates were obtained by suction filtration, specifically: pour polystyrene sol into a suction filtration device with double-layer filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com