Extraction process of vigna umbellata starch

An extraction process, red bean technology, applied in the field of food processing, to achieve the effect of improving the extraction rate and optimizing the starch extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

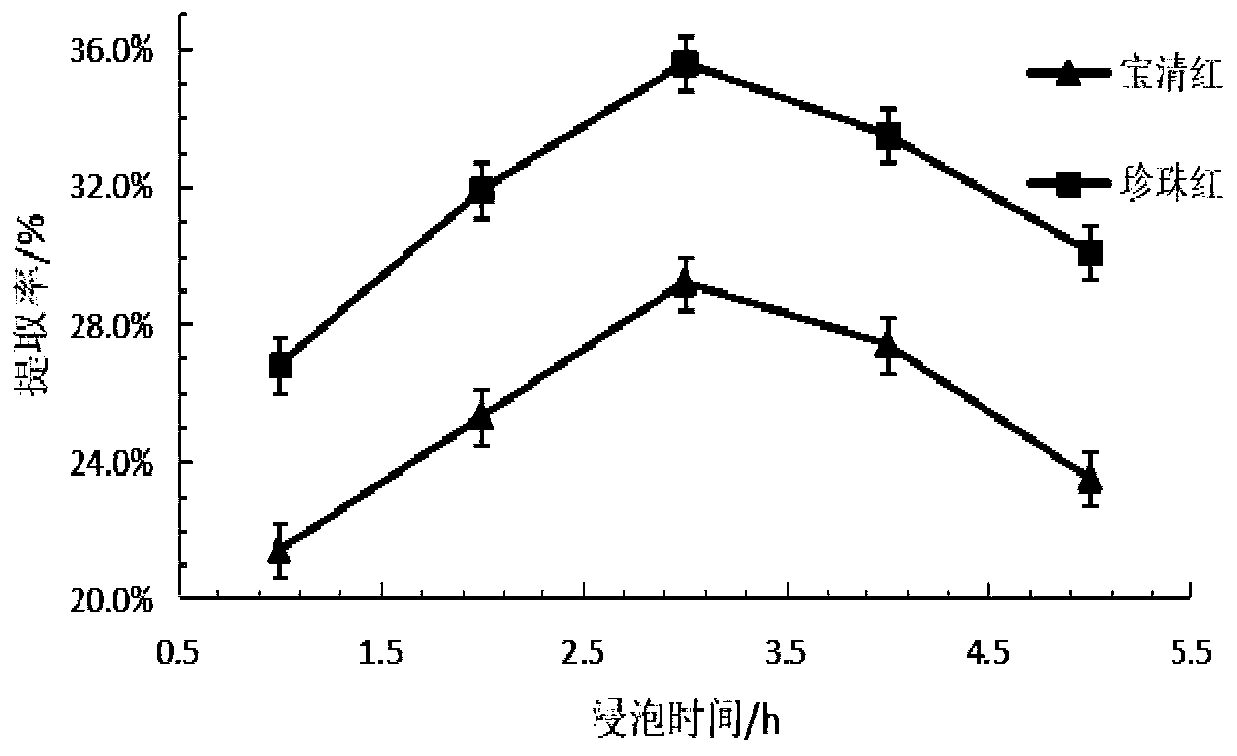

Image

Examples

Embodiment 1

[0026] Soak the red bean in water until the volume becomes larger and the seed coat becomes no longer hard. It is easy to rub the seed coat with your hands to make the seed coat fall off; after peeling, dry the red bean and crush it, then pass it through a 80-mesh sieve, and take The product under the sieve, according to the ratio of solid-liquid ratio of 1:2g / mL, add a sodium hydroxide solution with a mass percentage concentration of 0.1%, soak for 1h at a temperature of 25°C; then place it in a rotating speed of 4000r / min Centrifuge in a centrifuge for 10 minutes. After completion, discard the supernatant and remove the yellow-brown substance in the precipitate, wash it with water for 4 times, and continue the centrifugation until the starch slurry appears white; continue to use a molar percentage concentration of 1mol / Adjust the pH value of L sodium hydroxide solution to 7.0, centrifuge and transfer to a 30°C constant temperature incubator to dry, pass through an 80-mesh si...

Embodiment 2

[0028] Soak the red bean in water until the volume becomes larger and the seed coat becomes no longer hard. It is easy to rub the seed coat with your hands to make the seed coat fall off; after peeling, dry the red bean and crush it, then pass it through a 80-mesh sieve, and take The product under the sieve, according to the ratio of material to liquid is 1:3g / mL, add the sodium hydroxide solution that the mass percent concentration is 0.2%, soak 2h at the temperature of 30 ℃; Centrifuge in a centrifuge for 10 minutes. After completion, discard the supernatant and remove the yellow-brown substance in the precipitate, wash it with water for 4 times, and continue the centrifugation until the starch slurry appears white; continue to use a molar percentage concentration of 1mol / Adjust the pH value of L sodium hydroxide solution to 7.0, centrifuge and transfer to a 30°C constant temperature incubator to dry, pass through an 80-mesh sieve after completion, and take the product under...

Embodiment 3

[0030] Soak the red bean in water until the volume becomes larger and the seed coat becomes no longer hard. It is easy to rub the seed coat with your hands to make the seed coat fall off; after peeling, dry the red bean and crush it, then pass it through a 80-mesh sieve, and take The product under the sieve is 1:4g / mL according to the ratio of material to liquid, adding a sodium hydroxide solution with a mass percentage concentration of 0.3%, soaking at a temperature of 35°C for 3h; Centrifuge in a centrifuge for 10 minutes. After completion, discard the supernatant and remove the yellow-brown substance in the precipitate, wash it with water for 4 times, and continue the centrifugation until the starch slurry appears white; continue to use a molar percentage concentration of 1mol / Adjust the pH value of L sodium hydroxide solution to 7.0, centrifuge and transfer to a 30°C constant temperature incubator to dry, pass through an 80-mesh sieve after completion, and take the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com