Preparation methods of cumyl peroxyneodecanoate (CNP) and solvent type CNP

A technology of cumyl decanoate and cumene hydroperoxide, which is applied in the field of preparation of cumyl peroxyneodecanoate and solvent-based CNP, can solve the problem of shortening the production cycle, reducing the content of the water phase, and reducing labor Intensity and other issues, to achieve the effect of shortening the production cycle, improving the activity of the initiator, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

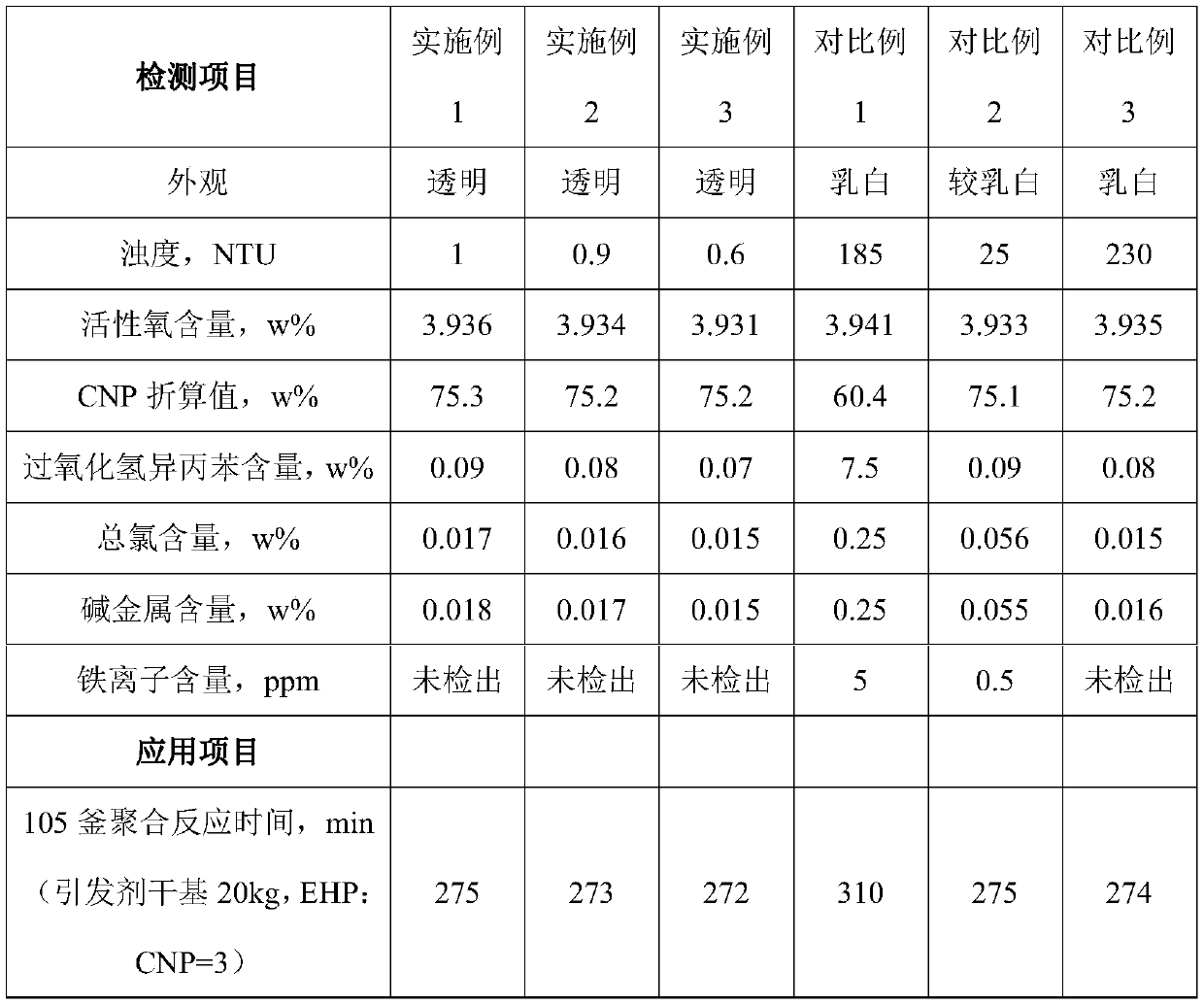

Examples

Embodiment 1

[0080] A kind of preparation method of solvent type cumyl peroxyneodecanoate comprises the steps:

[0081] synthesis:

[0082] (1) 600kg of cumene hydroperoxide is added dropwise in 25% potassium hydroxide lye, the dry basis mass ratio of said lye and cumene hydroperoxide is 0.4:1, the time for adding is 20min, dropwise Stir for 15 minutes after the addition to obtain solution 1;

[0083] (2) Add neodecanoyl chloride dropwise to solution 1, the dry basis mass ratio of cumene hydroperoxide to neodecanoyl chloride is 0.8:1, the dropwise addition time is 45min, after the dropwise addition is completed, react at 25°C for 60min , let it stand for 30 minutes, and divide the water to obtain a water-in-oil emulsion;

[0084] Purification:

[0085] (1) Wash the water-in-oil emulsion with 5% sodium hydroxide solution, the mass ratio of the dry basis of the sodium hydroxide to the water-in-oil emulsion is 0.06:1, leave it standing after washing, divide water, and obtain the solution ...

Embodiment 2

[0093] A kind of preparation method of solvent type cumyl peroxyneodecanoate comprises the steps:

[0094] synthesis:

[0095] (1) 600kg of cumene hydroperoxide is added dropwise in 35% sodium hydroxide lye, the dry basis mass ratio of said lye and cumene hydroperoxide is 0.6:1, the time for adding is 30min, dropwise Stir for 20 minutes after the addition to obtain solution 1;

[0096] (2) Add neodecanoyl chloride dropwise to solution 1, the dry basis mass ratio of cumene hydroperoxide to neodecanoyl chloride is 1.0:1, the dropping time is 60min, after the dropping is completed, react at 35°C for 90min , let it stand for 45 minutes, and divide the water to obtain a water-in-oil emulsion;

[0097] Purification:

[0098] (1) Wash the water-in-oil emulsion with 25% potassium hydroxide solution, the mass ratio of the dry basis of the potassium hydroxide to the water-in-oil emulsion is 0.1:1, leave it standing after washing, divide water, and obtain the solution 2;

[0099] (2...

Embodiment 3

[0106] A kind of preparation method of solvent type cumyl peroxyneodecanoate comprises the steps:

[0107] synthesis:

[0108] (1) 600kg cumene hydroperoxide is added dropwise in 30% potassium hydroxide lye, the dry basis mass ratio of said lye and cumene hydroperoxide is 0.5:1, and the time for adding is 25min, dropwise Stir for 30 minutes after the addition to obtain solution 1;

[0109] (2) Add neodecanoyl chloride dropwise to solution 1, the mass ratio of cumene hydroperoxide to neodecanoyl chloride on a dry basis is 0.9:1, and the dropping time is 50 minutes. After the dropping is completed, react at 30°C for 75 minutes , let it stand for 36 minutes, and divide the water to obtain a water-in-oil emulsion;

[0110] Purification:

[0111] (1) Wash the water-in-oil emulsion with 15% sodium hydroxide solution, the mass ratio of the dry basis of the sodium hydroxide to the water-in-oil emulsion is 0.08:1, leave it standing after washing, divide water, and obtain the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com