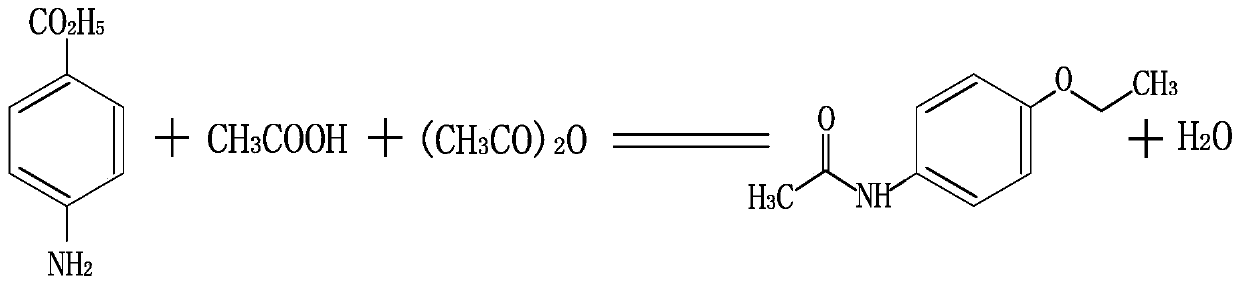

Synthesis process method and device of 4-acetophenetidine bulk drug

A technology for p-aminophenethyl ether and acetaminophen, which is applied in the field of raw material drug production, can solve problems such as complicated processes, limited raw materials, etc., and achieve the effects of easy availability of raw materials, novel overall structure, and convenient actual production and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw material ratio: the molar ratio of p-aminophenethyl ether: acetic anhydride: glacial acetic acid is: 1: 0.5: 0.75;

[0033] Proportion of raw materials: p-aminophenethyl ether (98.0% content) 160kg, acetic anhydride (99.0% content) 73.6L, glacial acetic acid (99.80% content) 120L.

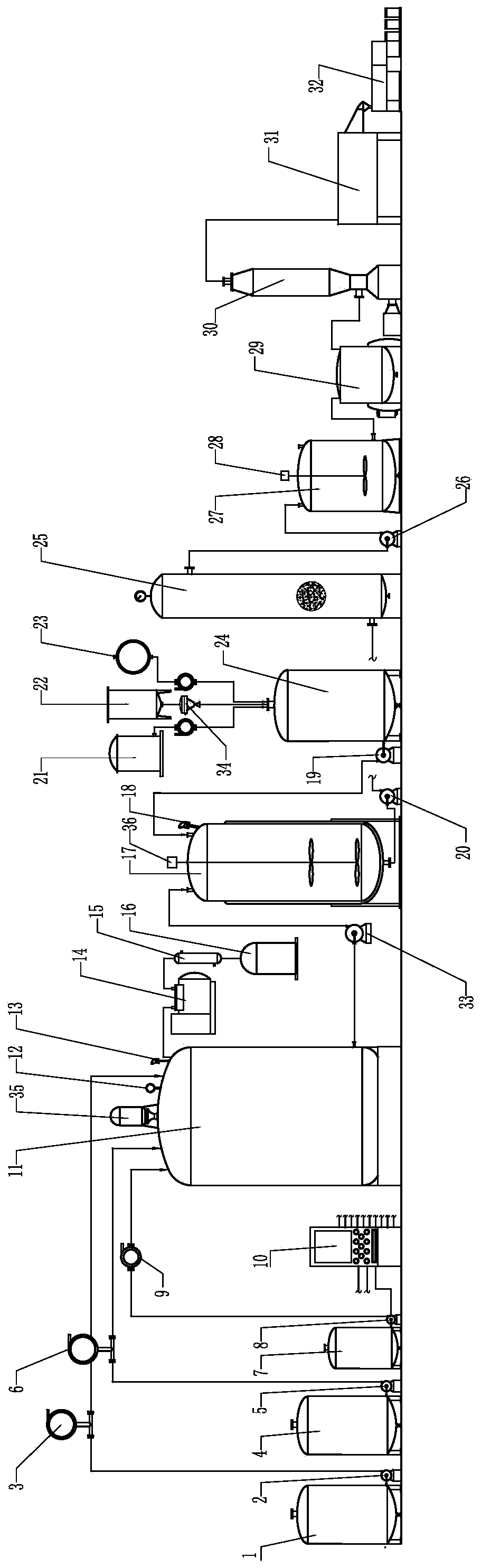

[0034] The synthetic production process of the p-acetamidophenetole of this embodiment concrete procedure is as follows:

[0035] (1) Etification reaction process: First, according to the above-mentioned ratio of ingredients, after measuring and weighing p-aminophenethyl ether, acetic anhydride, and glacial acetic acid, first add 100L of glacial acetic acid to the reaction kettle, heat up to boiling, and add p-aminophenethyl ether to In the reaction kettle, after stirring for 3 minutes, heat up to boiling, reduce the pressure of the reaction kettle to 0.25MPa through the chain pressure of the steam valve, control the temperature in the kettle at 124±3℃, and then increase it by 0.05MPa ev...

Embodiment 2

[0041] Raw material ratio: the molar ratio of p-aminophenethyl ether: acetic anhydride: glacial acetic acid is: 1: 0.46: 0.72;

[0042] Feeding amount: p-aminophenethyl ether (98.0% content) 140kg; acetic anhydride (99.0% content) 64.4L; glacial acetic acid (99.80% content) 101L.

[0043] The preparation of para-acetaminophenethyl ether product process described in the present embodiment is by following operation:

[0044] ⑴. Etching reaction process: First, according to the molar ratio of the above ingredients, after weighing p-aminophenethyl ether, acetic anhydride, and glacial acetic acid, first add 86L glacial acetic acid into the reaction kettle, heat up to 100-108°C and boil, Add 140kg of aminophenethyl ether and stir for 3 minutes, then raise the temperature to boiling, reduce the pressure of the reactor to 0.25MPa through the chain pressure of the steam valve, control the temperature in the kettle at 124±2°C, and then increase it by 0.05MPa every 20 minutes, and rise t...

Embodiment 3

[0050] Raw material ratio: p-aminophenethyl ether: acetic anhydride: the molar ratio of glacial acetic acid is: 1.0: 0.5: 1.16.

[0051]Feeding amount: p-aminophenethyl ether (98.0% content) 100kg; acetic anhydride (99.0% content) 36.1L, glacial acetic acid (99.80% content) 49.7L.

[0052] Present embodiment makes p-acetamidophenetole product technological method by following operation:

[0053] (1) Etification reaction process: First, according to the molar ratio of the above-mentioned ingredients, after weighing p-aminophenethyl ether, acetic anhydride, and glacial acetic acid, add 85% of the total amount of glacial acetic acid to the reaction kettle, heat up to boiling, and add the Add aminophenethyl ether to the reactor, stir for 2-3 minutes, then raise the temperature to boiling, reduce the pressure of the reactor to 0.25MPa through the chain pressure of the steam valve, control the temperature in the reactor at 124±1°C, and then increase it every 20 minutes 0.05MPa, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com