Plate part storage device and storage and taking method thereof

A storage device and access method technology, applied in packaging, internal accessories, transportation and packaging, etc., can solve the problems of increased production costs, cumbersome operations, and large storage space, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples.

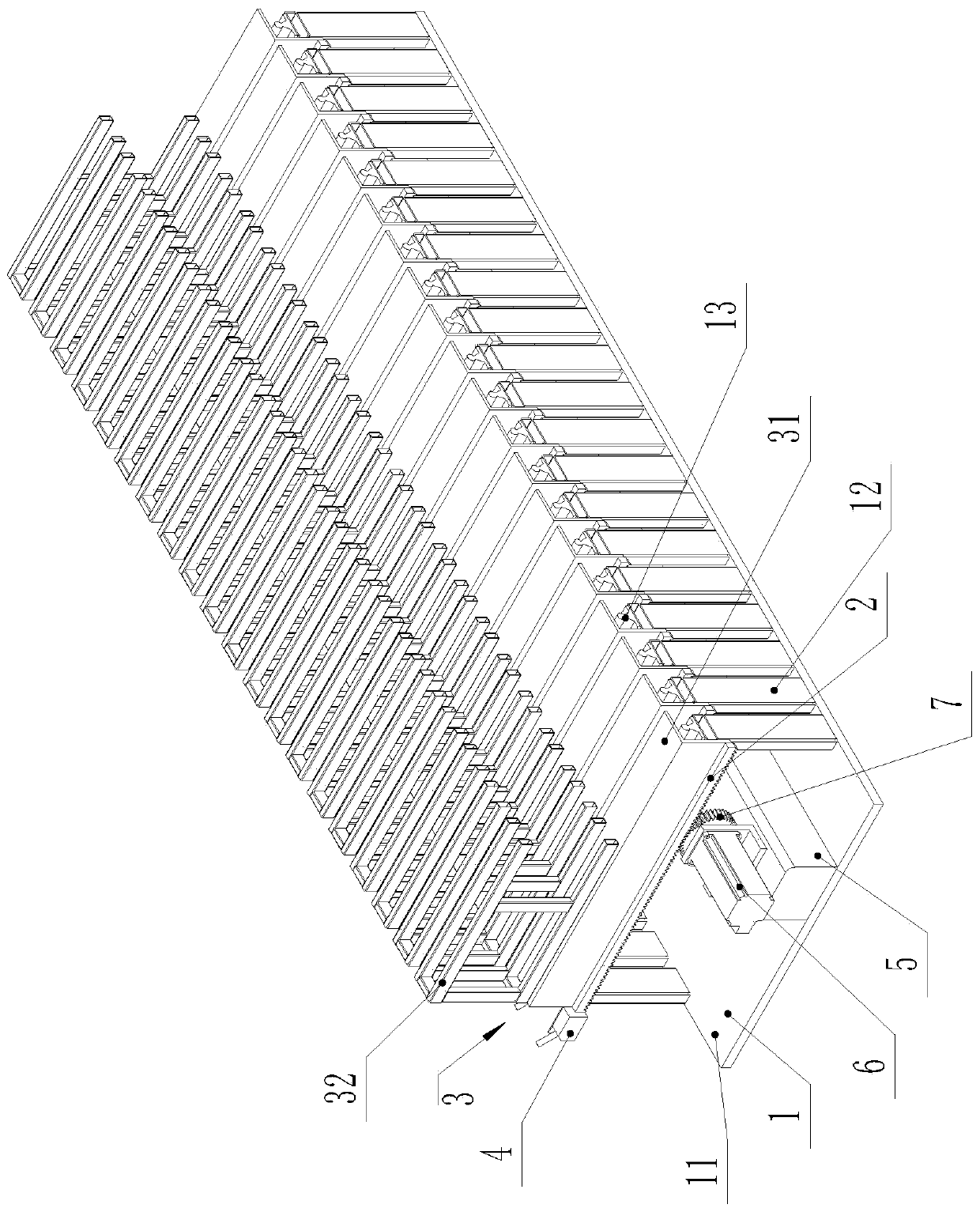

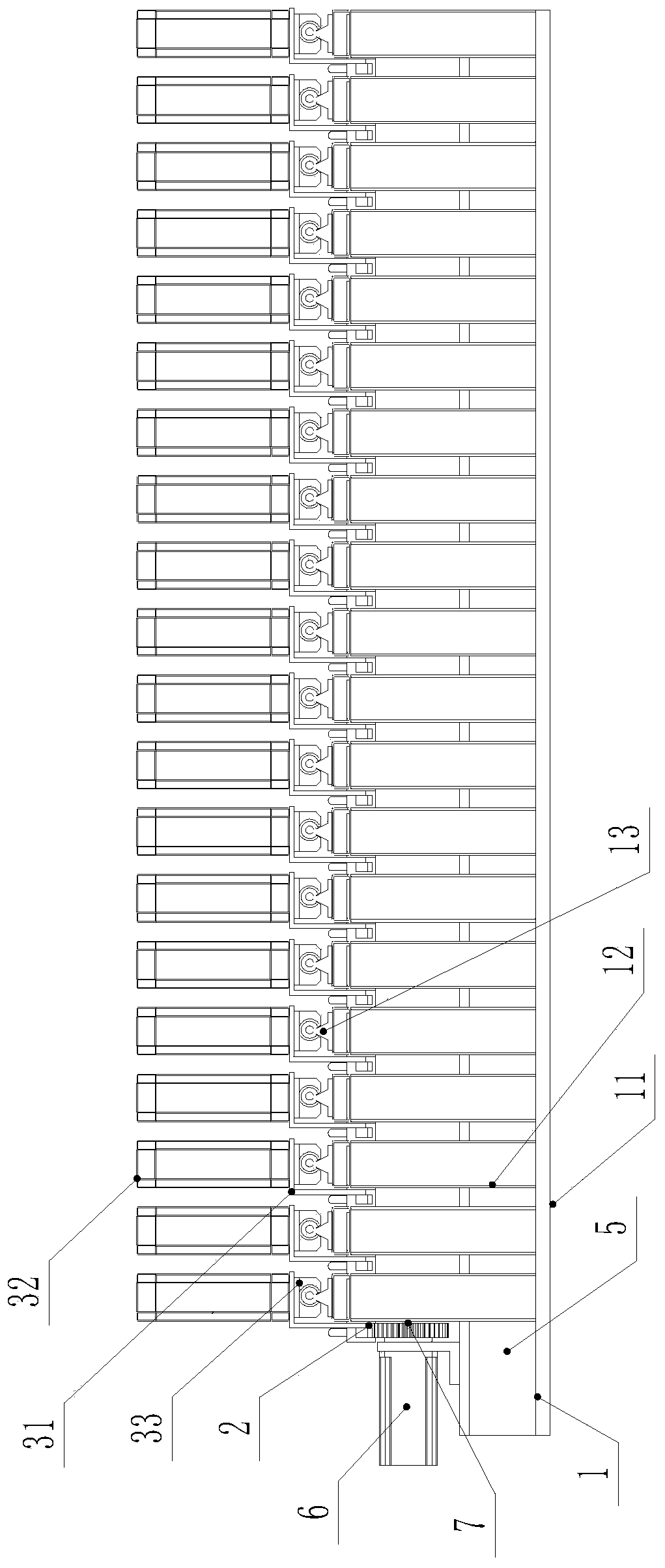

[0026] Such as Figure 1 to Figure 3 As shown, a storage device for plate parts includes a base 1 on which several storage frames 3 for placing upright plate parts are installed, and the storage frames 3 are arranged along the length direction of the base 1, Arranged at intervals, each storage frame 3 has the same structure.

[0027] Wherein said base 1 comprises an installation base plate 11 and several support frames 12 arranged at equal intervals arranged on the installation base plate 11, the top of each support frame 12 is provided with a transverse guide rail 13, and each storage base plate 31 is slidably installed on On the corresponding transverse guide rail 13, the support frame 12 is welded into a structure similar to a rectangular frame by adopting rectangular profiles, and the bottom of the support frame 12 is welded or bolted to the installation point.

[0028] Ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com