Low-temperature flue gas desulfurization and denitrification coupling absorption process capable of reducing oxidant escape

A technology for desulfurization and denitrification, low-temperature flue gas, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of oxidant surplus and escape, achieve effective coupling, shorten the process, and solve the effect of secondary pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

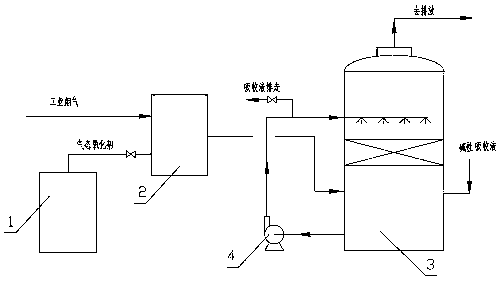

[0020] like figure 1 Shown: a low-temperature flue gas desulfurization and denitrification coupling absorption process to reduce oxidant escape, the process is as follows: use oxidants to oxidize the nitrogen oxides containing low-valence nitrogen in the flue gas to nitrogen oxides with high-valence nitrogen; and then Send the flue gas containing nitrogen oxides of high valence nitrogen into the desulfurization and denitrification coupling absorption tower 3, and use alkaline solution absorbent in the desulfurization and denitration coupling absorption tower 3 to absorb the nitrogen oxides of high valence nitrogen in the flue gas into nitric acid Salt, the SO in the flue gas 2 Absorbed as sulfite and bisulfite, so as to achieve the purpose of desulfurization and denitrification at the same time; at the same time, the residual oxidant in the flue gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com