THF rectification equipment for PBT production

A rectification and rectification two-tower technology, applied in the field of THF rectification device, can solve the problems of tail gas treatment system load increase, THF and heat loss, THF loss, etc., achieve good economic benefits, reduce energy consumption, and use energy full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

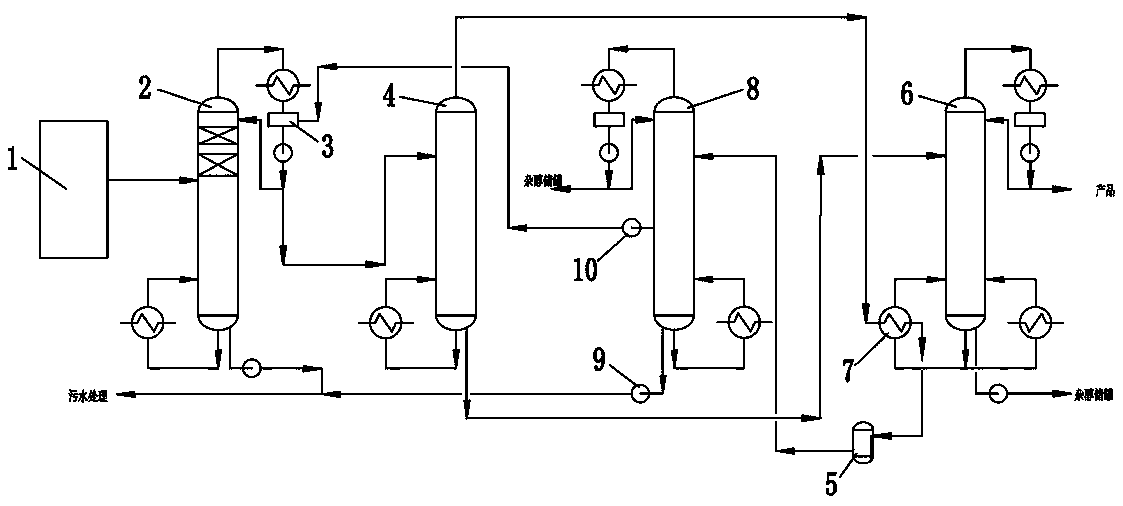

[0018] Such as figure 1 Shown, a kind of THF rectification device that is used for PBT production comprises THF waste water device 1, rectification one tower 2, rectification two tower 4, rectification three tower 6, rectification four tower 8, described rectification one Tower 2, rectification third tower 6, rectification fourth tower 8 are equipped with overhead condensers, reflux tanks and reflux pumps, and the bottom of the towers are equipped with extraction pumps and reboilers, and rectification third tower 4 is also equipped with There are three auxiliary reboilers 7, and the top of the second rectifying tower 4 is directly connected to the shell-side inlet of the third auxiliary reboiler 7, and the top of the second rectifying tower 4 is not provided with any equipment or structure forming reflux, and the The bottom of the second rectification tower 4 is connected to the middle and upper part of the third rectification tower 6 through a pipeline. The 7 shell-side inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com