A kind of preparation method of ha coating on the surface of titanium alloy substrate

A technology of titanium alloy and substrate, which is applied in the field of preparation of HA coating on the surface of titanium alloy substrate, can solve the problem of reduced biological activity of the coating, and achieve the effect of increasing the content of HA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the essence of the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

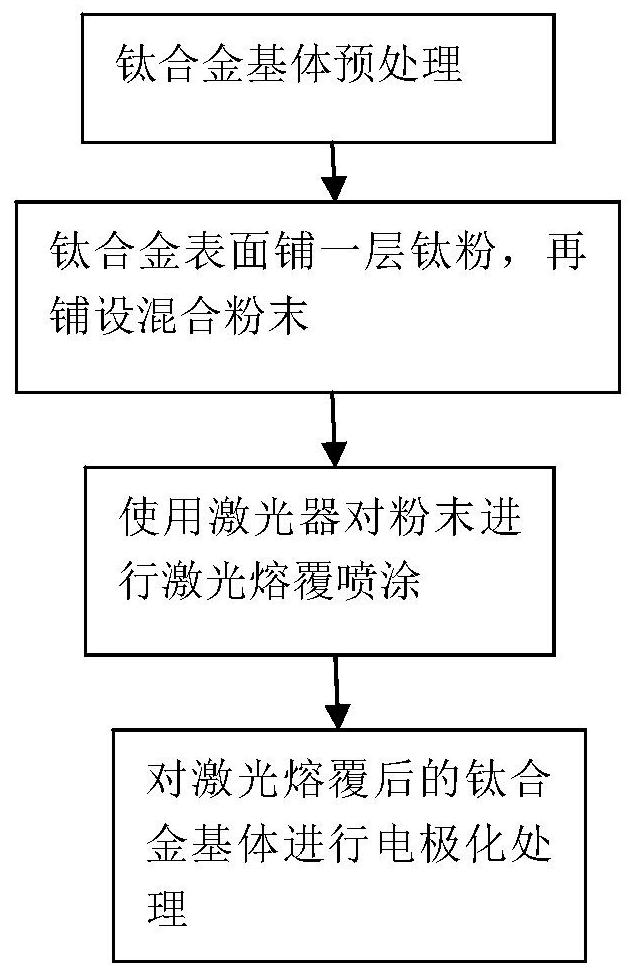

[0017] The present invention is suitable for the field of biomedical materials, especially for the preparation of medical implant coatings, specifically comprising the following steps:

[0018] Step 1: Pretreat the surface of the titanium alloy substrate.

[0019] After grinding the surface of the titanium alloy substrate, it was cleaned by ultrasonic vibration with distilled water, dried, sterilized by radiation, and placed for later use. The temperature of ultrasonic vibration cleaning is 50°C, and the ultrasonic working frequency is between 20 and 30KHz.

[0020] Step 2: The spray powder is sprayed on the surface of the treated titanium alloy substrate by laser cladding. The spraying powder includes mixed powder and titanium powder, and the mixed powder includes hydroxyapatite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com