Heat insulation part for non-combustible tobacco heater

A heat-not-burn, heat-insulating technology, applied in tobacco and other directions, can solve the problem of overheating the outer surface of the heating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

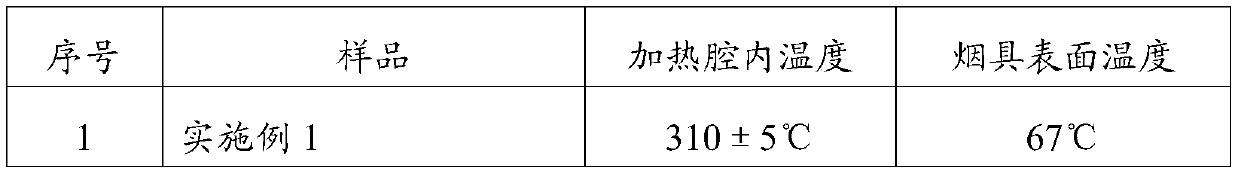

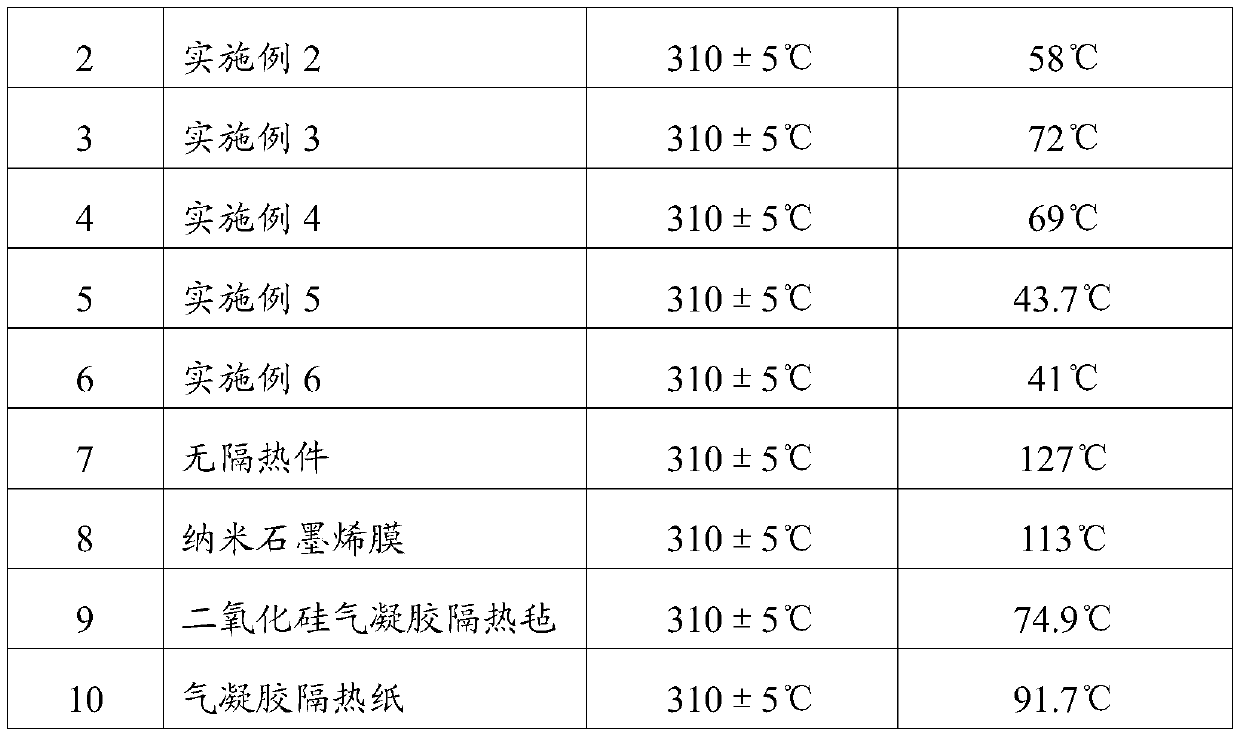

Examples

Embodiment 1

[0070] Embodiment 1: The present invention is used for heat insulation element of heat not burn tobacco heater

[0071] The implementation mode of this embodiment is as follows:

[0072] The heat insulation part is between the heating cavity of the heat-not-burn tobacco heater and the smoking device shell, and it is composed of nano-graphene film (103) and airgel heat-insulating paper (102) through adhesive (104) Bonded, wherein the thickness ratio of the nano-graphene film (103), the adhesive (104) and the airgel thermal insulation paper (102) is 2:0.05:1.

[0073] in:

[0074] The nano-graphene film (103) is a combination of nano-graphene sold by Foshan Nuanyangyang Electric Heating Technology Co., Ltd. under the trade name NZW-013 Graphene and manufactured by Dongguan Xinchangmei Film Technology Co., Ltd. The peel-off strong PE low-viscosity protective film sold by the famous optical grade PE protective film is compounded according to the thickness ratio of 1:1 with a deg...

Embodiment 2

[0079] Embodiment 2: The present invention is used for heat insulation element of heat not burn tobacco heater

[0080] The implementation mode of this embodiment is as follows:

[0081] The heat insulation part is between the heating cavity of the heat-not-burn tobacco heater and the smoking device shell, and it is composed of nano-graphene film (103) and airgel heat-insulating paper (102) through adhesive (104) Bonded, wherein the thickness ratio of the nano-graphene film (103), the adhesive (104) and the airgel thermal insulation paper (102) is 1:0.1:3.

[0082] Among them, the nano-graphene film (103) is a combination of nano-graphene sold by Jiangsu Mayo Electronic Technology Co., Ltd. under the trade name nano-graphene film and manufactured by Shenzhen Yihongfa Technology Co., Ltd. under the trade name PET by dry lamination. The PE low-viscosity protective film with a peel strength of 20g / cm and a stretch rate of 410 is compounded according to the thickness ratio of 1:1...

Embodiment 3

[0087] Embodiment 3: The present invention is used for heat insulation element of heat not burn tobacco heater

[0088] The implementation mode of this embodiment is as follows:

[0089] The heat insulation part is between the heating cavity of the heat-not-burn tobacco heater and the smoking device shell, and it is composed of nano-graphene film (103) and airgel heat-insulating paper (102) through adhesive (104) Bonded, wherein the thickness ratio of the nano-graphene film (103), the adhesive (104) and the airgel thermal insulation paper (102) is 3:0.08:1.

[0090] Among them, the nano-graphene film (103) is a combination of nano-graphene sold by Jiangsu Mayo Electronic Technology Co., Ltd. under the trade name nano-graphene film and manufactured by Shenzhen Yihongfa Technology Co., Ltd. under the trade name PE. The PE low-viscosity protective film with a peel strength of 15g / cm and a stretch rate of 420 is compounded according to the thickness ratio of 1:1;

[0091] Measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com