Fresh wet noodles with long-term wheat flavor and preparation method thereof

A technology for fresh and wet noodles and aroma, applied in the field of pasta processing, can solve the problems affecting the commodity value of products, the deterioration of wheat aroma and high moisture content, and achieve the effects of preventing the escape of aromatic substances, reducing the amount of bacteria and reducing the moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 100g of sodium ascorbate and 2kg of salt to 80kg of water to form a saline solution, mix 9kg of wheat germ powder, 4kg of chestnut resistant starch, 3kg of soybean protein isolate and 8kg of carrageenan, then add 150kg of flour, mix well, then add the saline solution, knead Make the flour into a flocculent shape, which can be held into a ball by hand, and a loose flocculent dough can still be formed by kneading; knead the flocculent dough into a ball, wrap it in plastic wrap, and then put it in a 40°C incubator to proof for 30 minutes. The noodle press presses the proofed dough into slices and cuts into strips, adjusts the fixed gap, presses into slices and cuts into strips to get wet noodles. Wet noodles are processed under 620W microwave, and the processing time is controlled at 50s. After cooling, fresh wet noodles are obtained, and then measured and packaged under sealed and aseptic conditions.

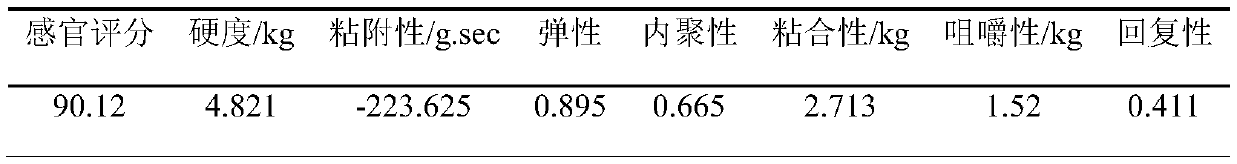

[0034] The sensory score of fresh wet noodles was 93.54, the hardn...

Embodiment 2

[0039] Add 150g of sodium ascorbate and 3kg of salt to 70kg of water to form a saline solution, mix 9kg of wheat germ flour, 5kg of chestnut resistant starch, 4kg of soybean protein isolate and 8kg of carrageenan, add it to 100kg of flour, then add the saline solution, and knead the dough , so that the flour becomes flocculent, which can be held into a ball by hand, and can still become a loose flocculent dough when kneaded; the flocculent dough is kneaded into a ball, wrapped in plastic wrap, and then placed in a 35°C incubator to proof for 40 minutes. Press the proofed dough and cut into strips, adjust the fixed gap, press and cut into strips to get wet noodles; process the wet noodles under 640W microwave, the processing time is controlled at 40s, after cooling to get fresh wet noodles, and then in Sealed, measured and packaged under sterile conditions.

[0040] The sensory score of fresh wet noodles was 94.23, the hardness was 5.223kg; the cohesion was 133.856g·sec; the re...

Embodiment 3

[0045]Add 200g of sodium ascorbate and 4kg of salt to 60kg of water to form a saline solution, mix 8kg of wheat germ powder, 3kg of chestnut resistant starch, 2kg of soybean protein isolate and 5kg of carrageenan, add it to 100kg of flour, mix well, and then add the saline solution , knead the dough to make the flour into a flocculent shape, which can be held into a ball by hand, and a loose flocculent dough can still be formed by kneading; knead the flocculent dough into a ball, wrap it in plastic wrap, and then put it in a 35°C incubator to proof After 40 minutes, the noodle press machine will press the proofed dough into slices and cut into strips, adjust the fixed gap, press into slices and cut into strips, and get wet noodles; process the wet noodles with 640W microwave power, control the processing time at 40s, and get fresh noodles after cooling. Wet surface, measured and packaged under sealed and aseptic conditions.

[0046] The sensory score of fresh wet noodles was 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com