A method for fast tin conduction of multi-layer interconnected FPC

A fast and conductive technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problem of pad size limitation, not being well solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

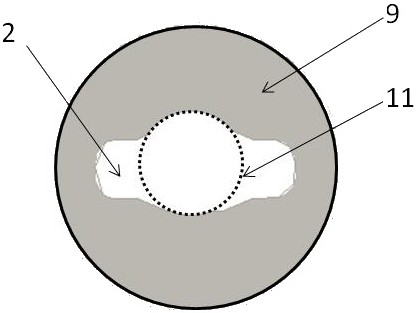

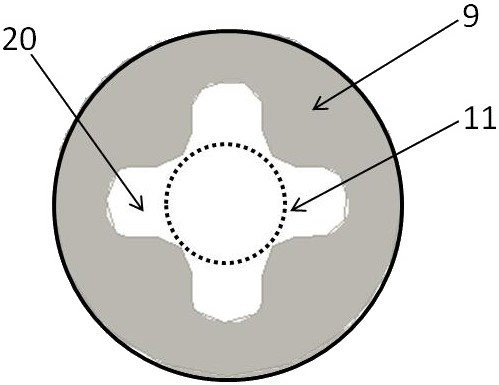

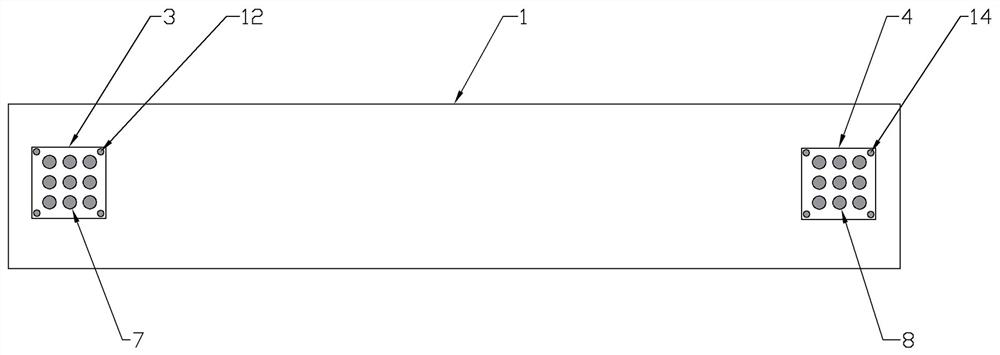

[0021] like Figure 1 to Figure 6 As shown, in this embodiment, a multilayer interconnection FPC realizes a method for fast tin conduction, the multilayer interconnection FPC applied to the method includes a main FPC1 and an auxiliary FPC2, and the main FPC1 is provided with a main output area 3 and a Main input area 4, said auxiliary FPC2 is provided with auxiliary output area 5 and auxiliary input area 6; said main output area 3 is provided with several main output pads 7 connected with said main FPC1 circuit, said main Several main input pads 8 connected to the main FPC1 circuit are arranged in the input area 4, and several main input pads 8 connected to the auxiliary FPC2 circuit and connected to the main input pad 8 are arranged in the auxiliary output area 5. A corresponding auxiliary output pad 9, the auxiliary input area 6 is provided with several auxiliary input pads 10 connected to the auxiliary FPC2 circuit and corresponding to the main output pad 7 one-to-one, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com