Sand control pipe for oil-sand separation in oil and gas exploitation

A technology for oil and gas exploitation and sand control pipes, which is applied in the field of separation of liquid-solid two-phase devices, can solve the problems of system permeability decrease, sand control time is short, and permeability is less than 40%, so as to speed up the inflow speed and keep sand The effect of good performance and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

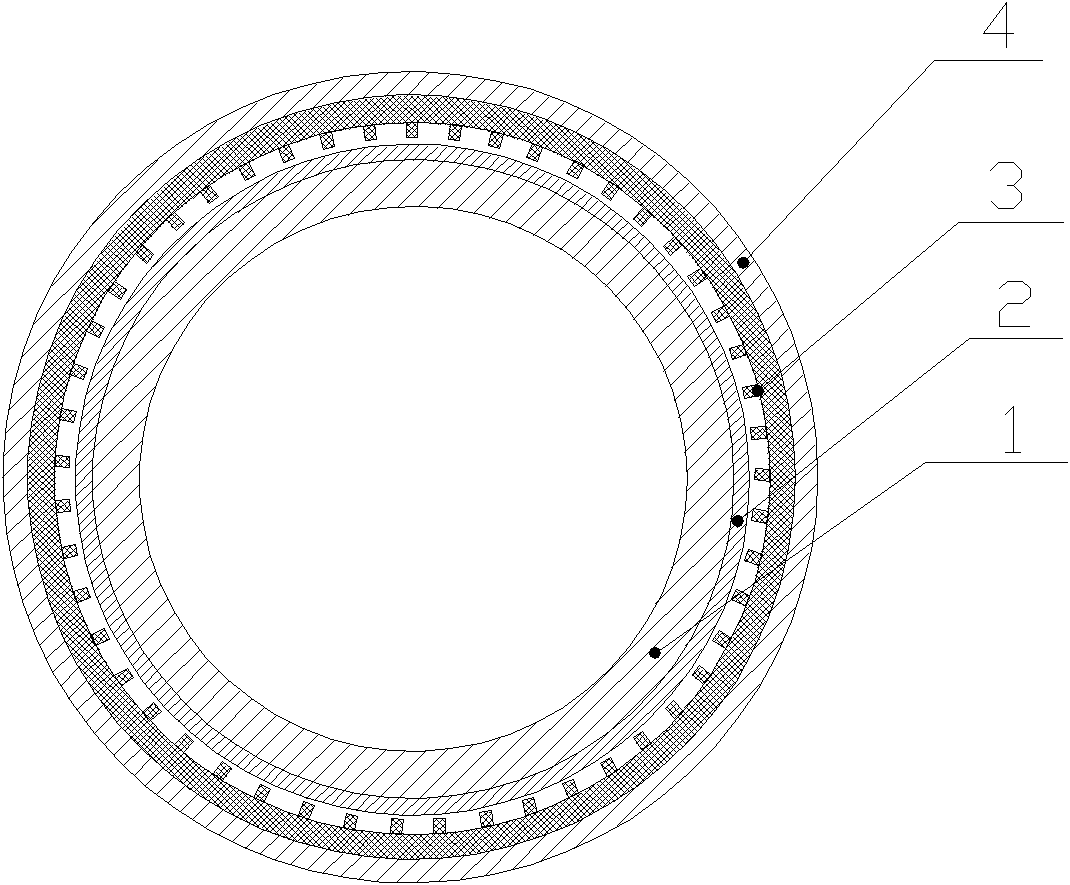

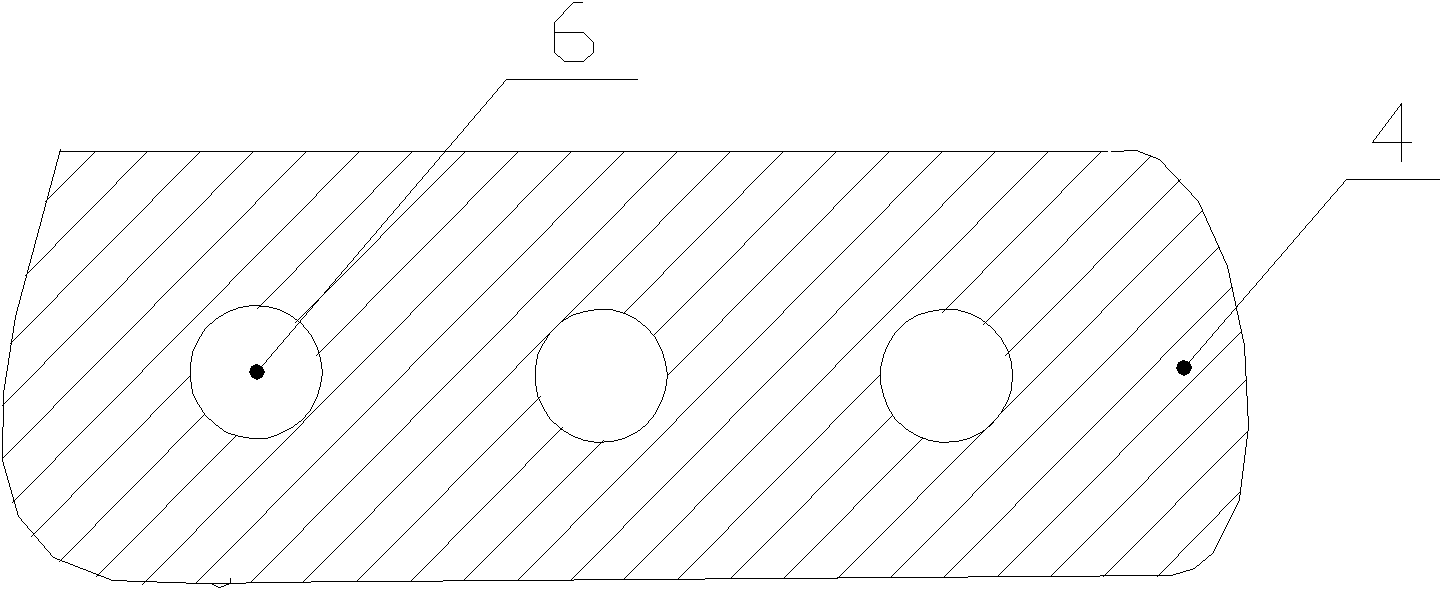

[0013] Such as figure 1 The sand control pipe shown is composed of a base pipe 1, an inner protective cover 2, a filter layer 3 and an outer protective cover 4 from the inside to the outside, wherein the inner protective cover, the filter layer and the outer protective cover are welded in sequence The sand control sleeve is fixed on the outside of the base pipe. Seepage holes are evenly distributed on the base pipe 1, such as figure 2 The shown outer protective cover 4 has several circular flow holes 6, and the inner protective cover 2 has the same flow holes.

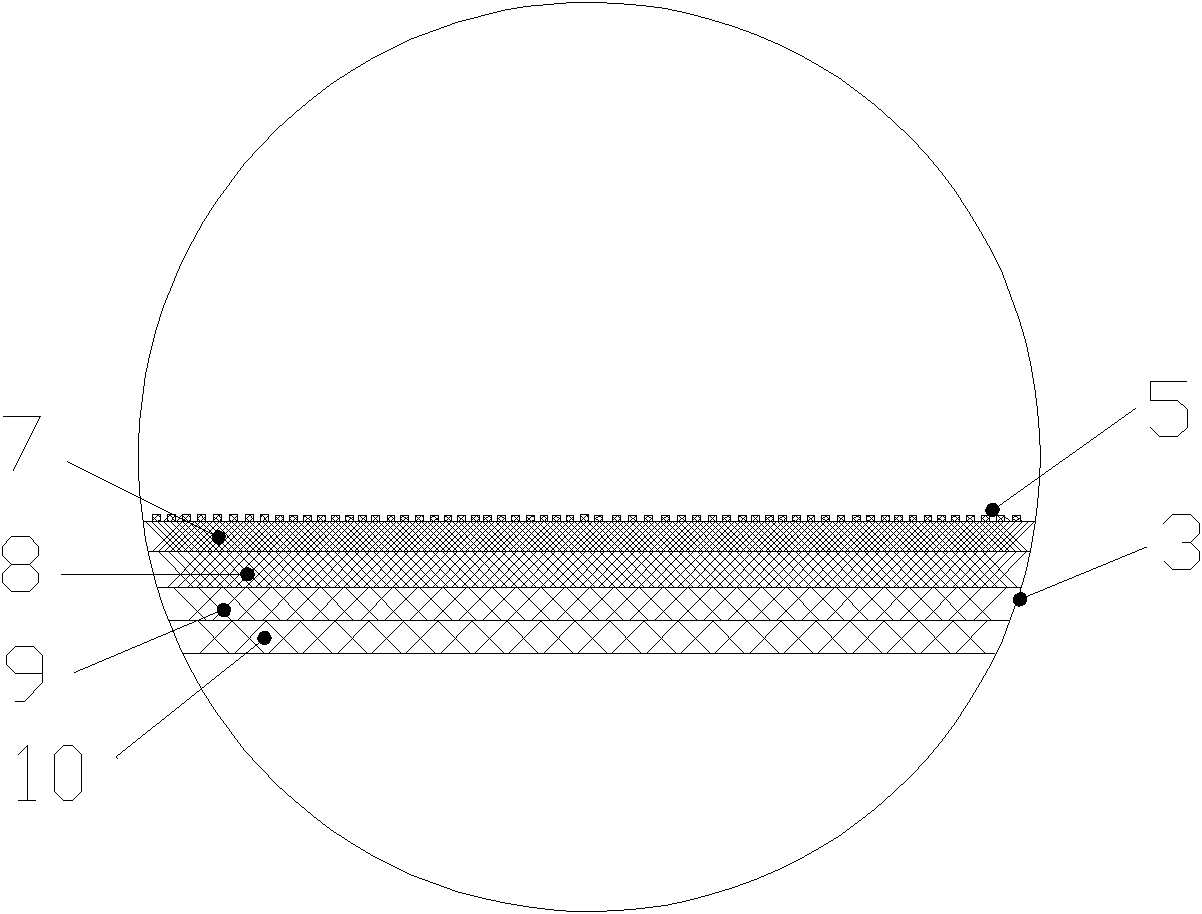

[0014] Take out the filter of the filter layer, such as image 3 As shown, the surface of the filter screen has uniform bumps 5, which are made of 4 layers of foamed nickel with different hole densities, and are made of foamed nickel 7, 8, 9 and 10 from the inside to the outside, and the innermost foamed nickel material 7. The hole density is 110PPI, the thickness is 2.0mm, and the bulk density of nickel metal is 1...

Embodiment 2

[0016] The sand control pipe is basically the same structure as in Example 1, except that the filter screen is different. Its surface is corrugated, and the filter screen is made of a foamed nickel-iron alloy material with a pore density of 95PPI and a thickness of 2.5mm. The bulk density of iron alloy is 2.0g / cm 3 .

Embodiment 3

[0018] Sand control pipe with basically the same structure as in Example 1, but the flow holes on the inner and outer protective covers of the sand control sleeve are square holes; the surface of the filter screen has uniform bumps, and is made of two layers of foam metal materials, and The layer is nickel foam with a pore density of 75PPI, a thickness of 3.0mm, and a bulk density of nickel metal of 2.0g / cm 3 ;The outer layer is foam nickel-iron alloy, its pore density is 55PPI, the thickness is 3.0mm, and the bulk density of nickel-iron alloy is 2.0g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com