Modified composite containing cavity sand control well completion screen pipe with flow dividing function

A diversion and modification technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problem of inability to adapt to the geological and production conditions of natural gas hydrate argillaceous silty sand reservoirs, filling materials and filling The problems of single particle size and large intrusion and blocking range of formation sand can achieve the effect of taking into account the sand retaining performance, improving the validity period of sand control, and reducing the degree of blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

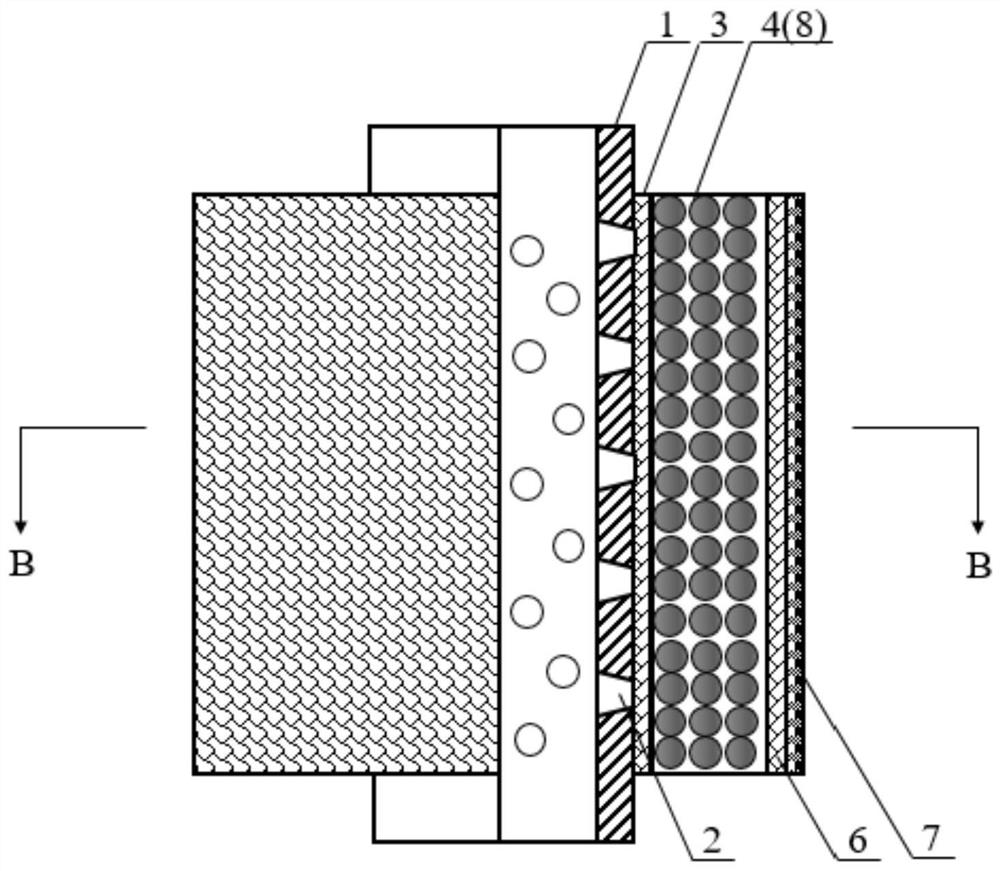

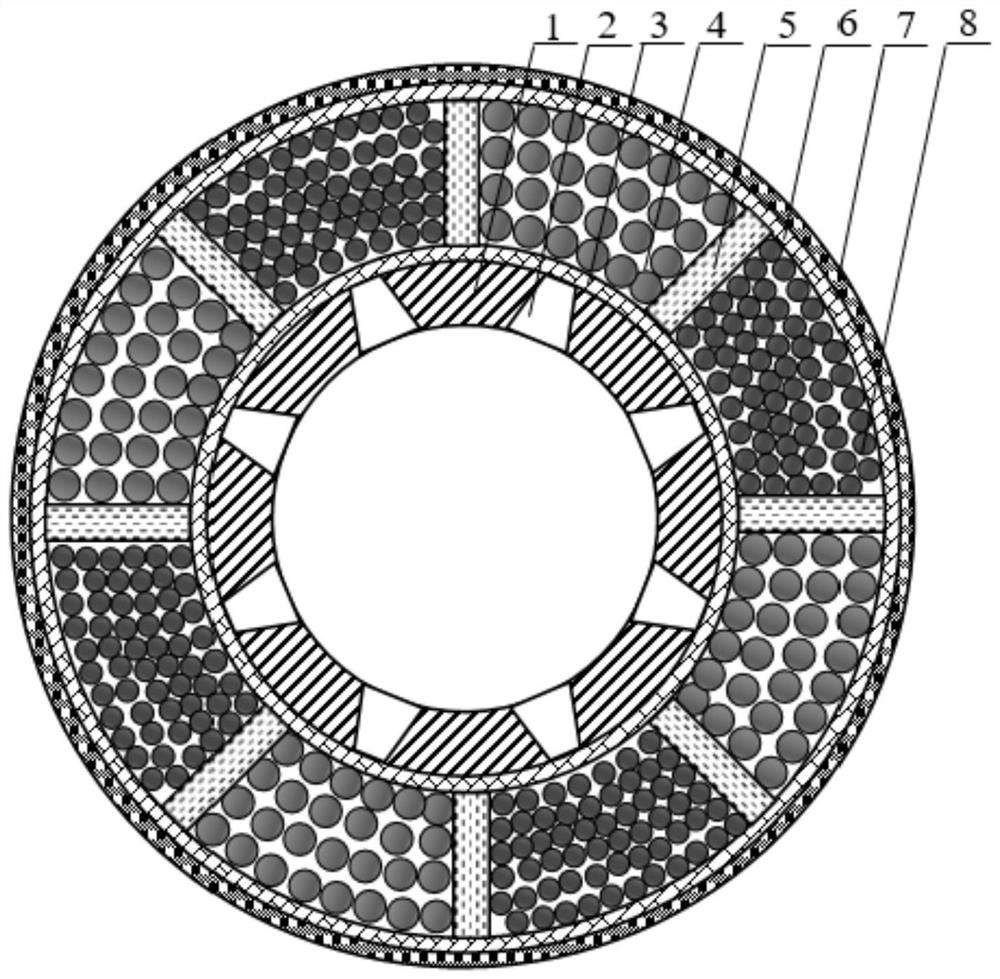

[0047] A modified compound cavity sand control completion screen with diverting effect, the structure is as follows figure 1 , figure 2 as shown,

[0048] The sand control completion screen includes from the inside to the outside in sequence:

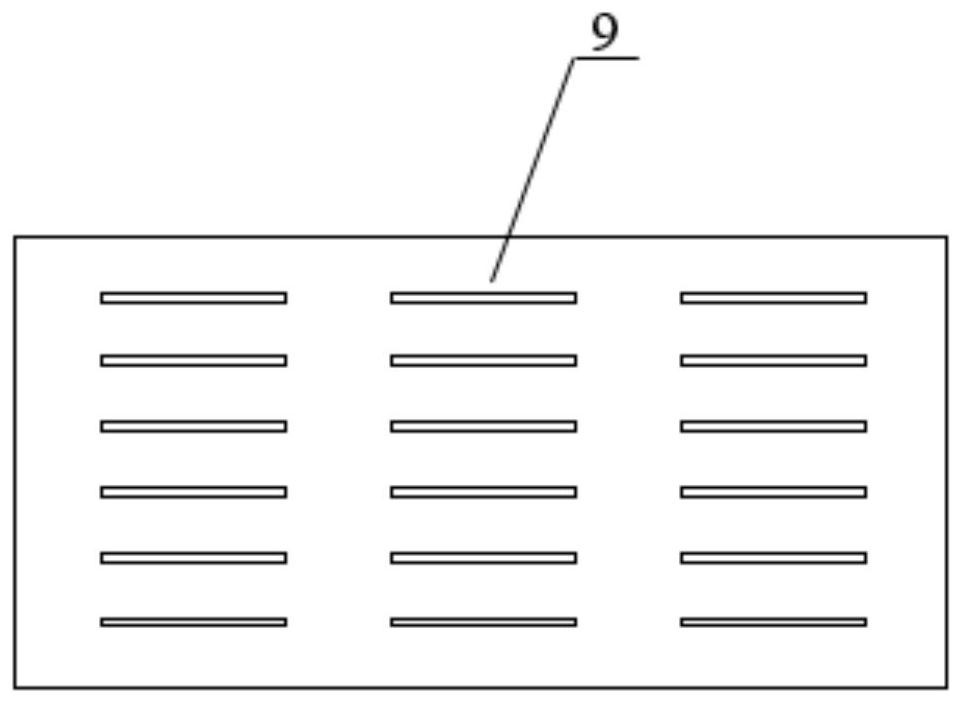

[0049] A base pipe 1, the base pipe 1 is provided with several diversion holes 2 communicating with the interior of the base pipe; the diversion holes 2 are circular with a diameter of 8-10mm. The base pipe is a central pipe with holes, and its main function is to ensure the overall strength of the screen pipe, support the pre-fill layer, and ensure fluid inflow;

[0050] The inner filter screen 3 set outside the base pipe; the material of the inner filter screen 3 is 316L, which is sintered by five layers of metal screens, the thickness is about 1.5-2.5mm, and the nominal accuracy is the second pre-filled layer of ceramsite 2 / 3 of the smallest particle size.

[0051] The outer filter 6 set outside the base pipe; the material of th...

Embodiment 2

[0056] It is the same as the modified composite cavity sand control completion screen described in Example 1, the difference is that:

[0057] Both the first pre-fill layer 4 and the second pre-fill layer 8 have a thickness of 50mm, the first pre-fill layer 4GSR is 14mm, and the second pre-fill layer GSR is 11mm.

experiment example

[0065] Experimental example: Sand retaining and plugging effect test

[0066] Test method: use the sand control performance evaluation experimental device of the gravel layer, and then simulate the gas-water flow conditions in the process of natural gas hydrate exploitation, and use muddy silty sand to carry out the sand blocking simulation experiment of the gravel layer. During the experiment, by controlling variables to ensure that all experimental flows and formation sand conditions are consistent, ceramsite with a specified particle size is pre-filled in the radial flow displacement experimental device according to the specified method; at the beginning of the experiment, first mix the fluid with water and air Flood the gravel pack for a period of time, then use fluid to carry muddy silt and fine sand to displace the gravel pack for a long time, measure the pressure difference and fluid flow on both sides of the gravel pack; then change the gravel pack mode or size to maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com