Engine transmission hydraulic torque converter

A technology for hydraulic torque converters and gearboxes, which is applied in the direction of mechanical equipment, transmission devices, fluid transmission devices, etc. It can solve problems such as burrs and wear, poor oil flow, and easy formation of swirls, etc., to reduce Friction, increased device load, less prone to damage and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

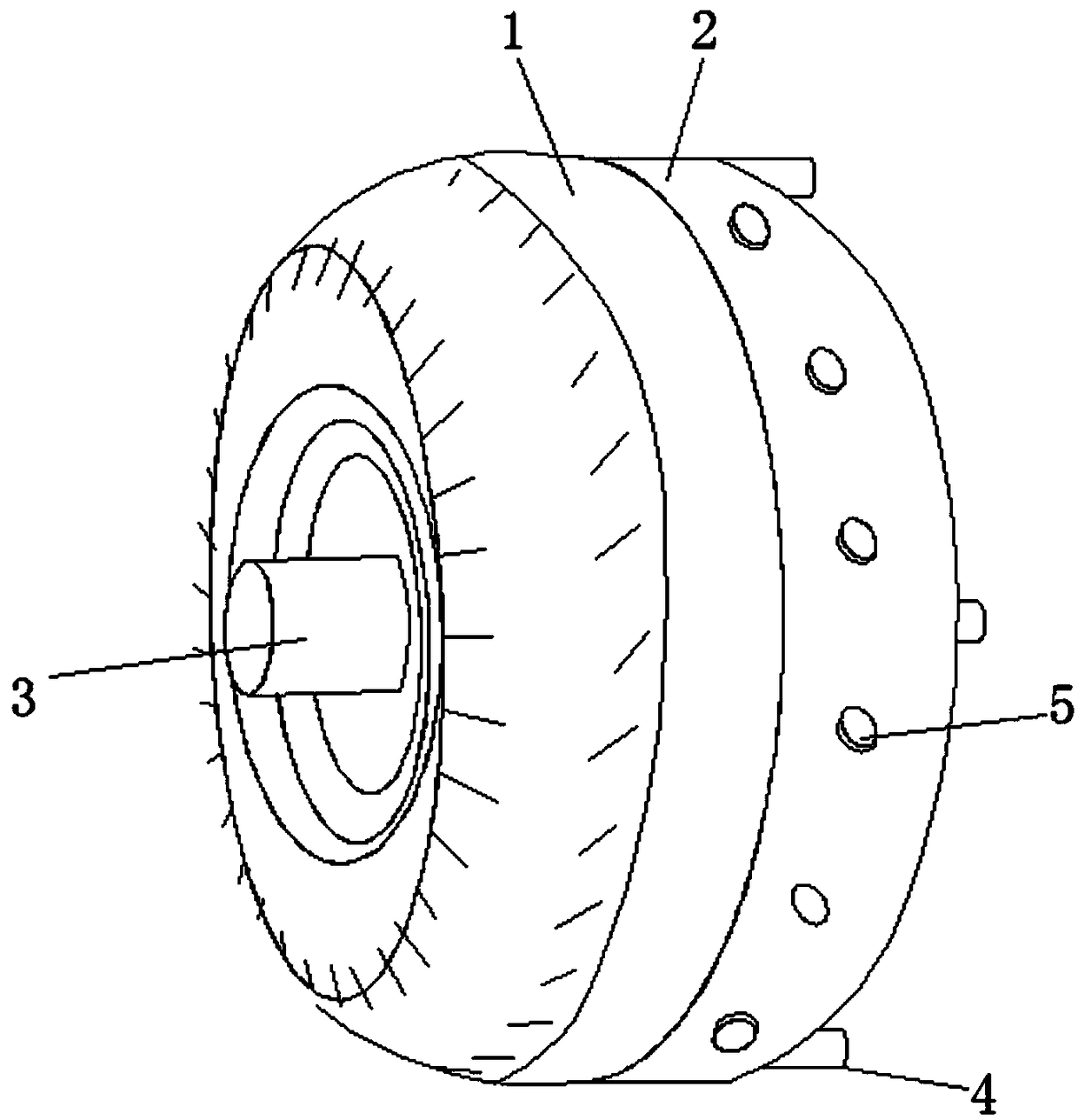

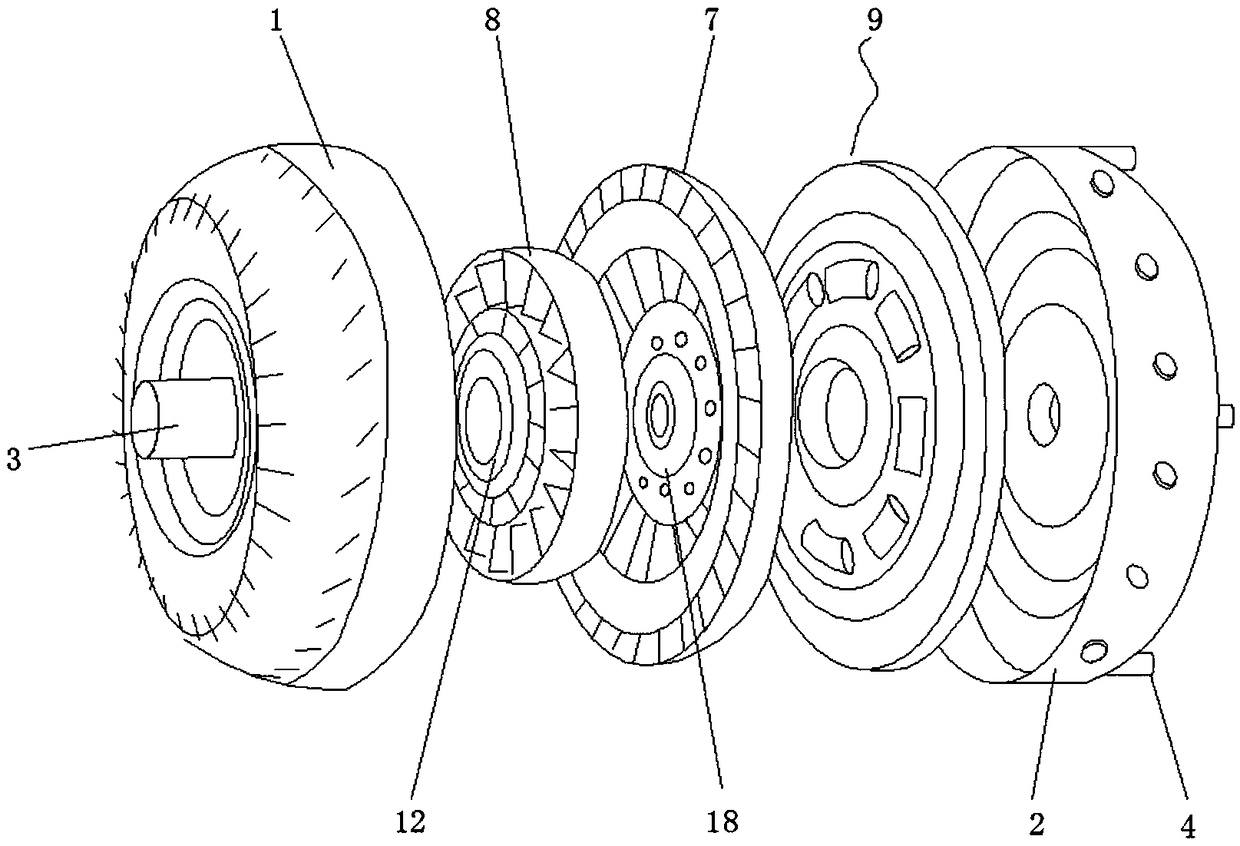

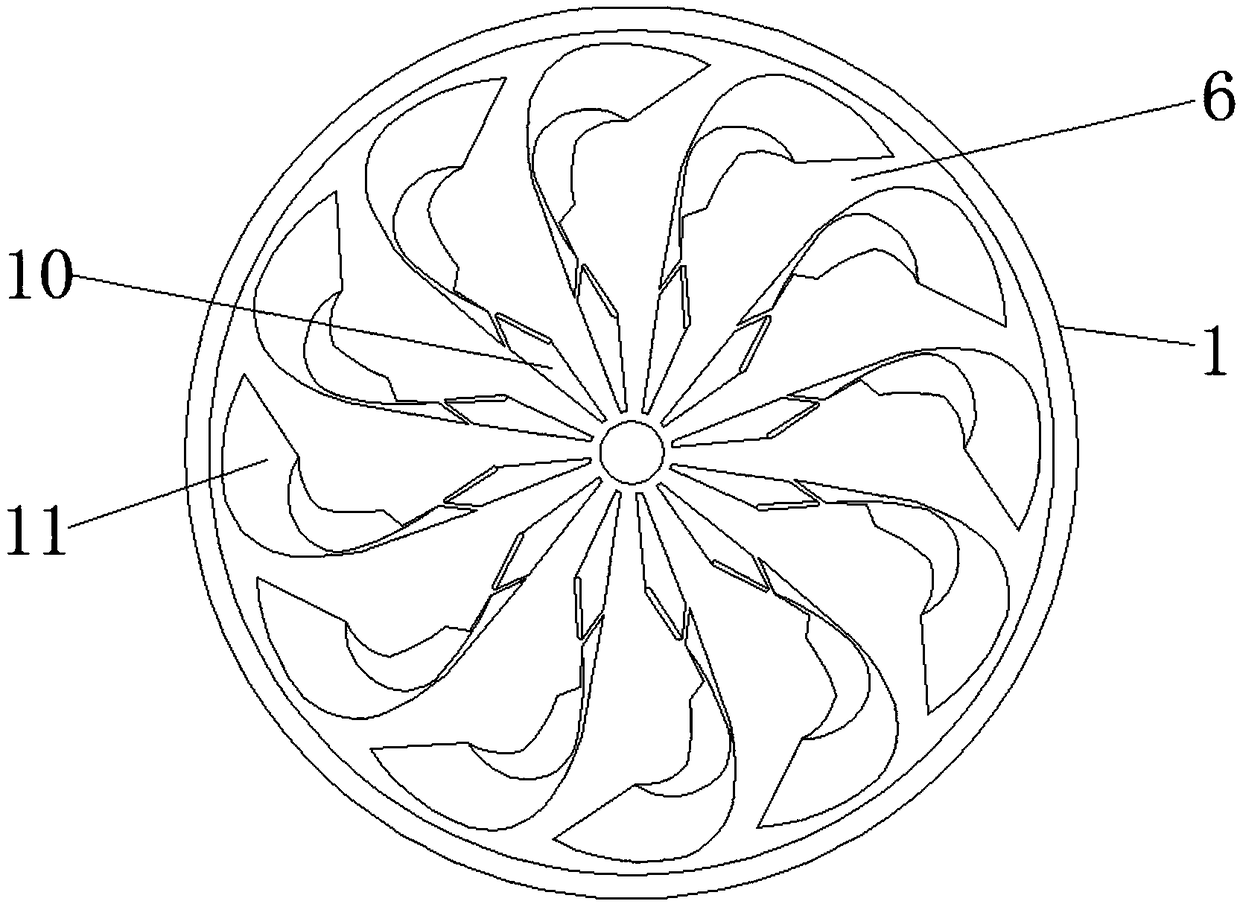

[0019] according to figure 1 , 2 , 3, 4, and 5, this embodiment provides a hydraulic torque converter for an engine gearbox, including a pump wheel housing 1 and a front housing cover 2, and a front housing cover is installed on one side of the pump wheel housing 1 2, and the drive interface 3 is provided at the middle position of the pump wheel housing 1 away from the side of the front housing cover 2, and the positioning bolt 4 is provided at the edge of the side of the front housing cover 2 away from the pump wheel housing 1, and the front housing cover 2 Install and fix the pump wheel housing 1 through the positioning bolts 4, the side wall of the front housing cover 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com