Device and method for accurately detecting wheel tread scratches and out-of-roundness

A wheel tread, accurate technology, applied in the field of rail transit, can solve the problem of low measurement accuracy, and achieve the effects of improving measurement efficiency, improving structural stability, and preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

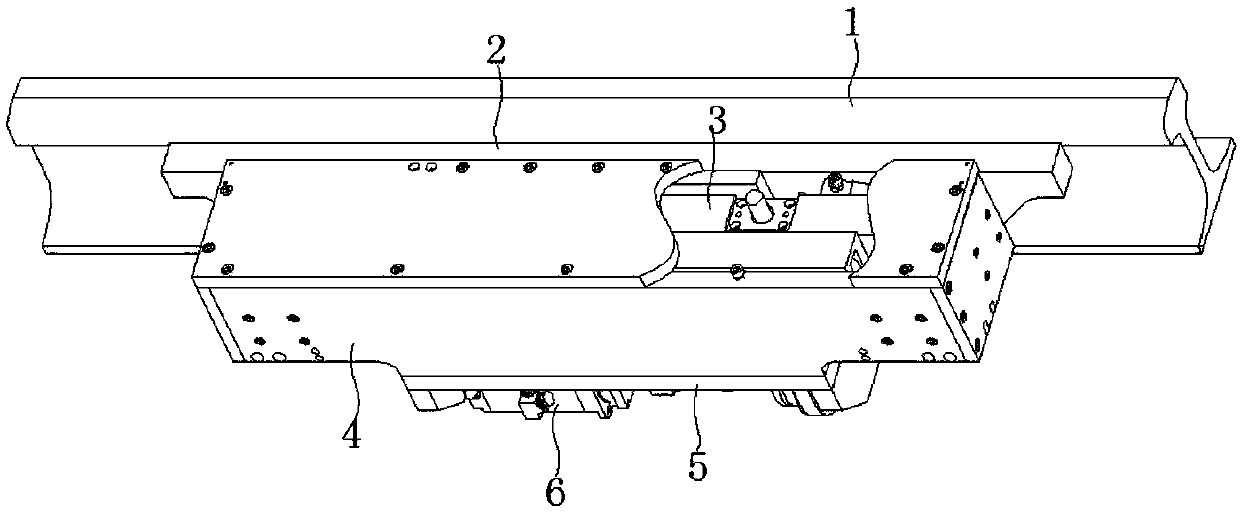

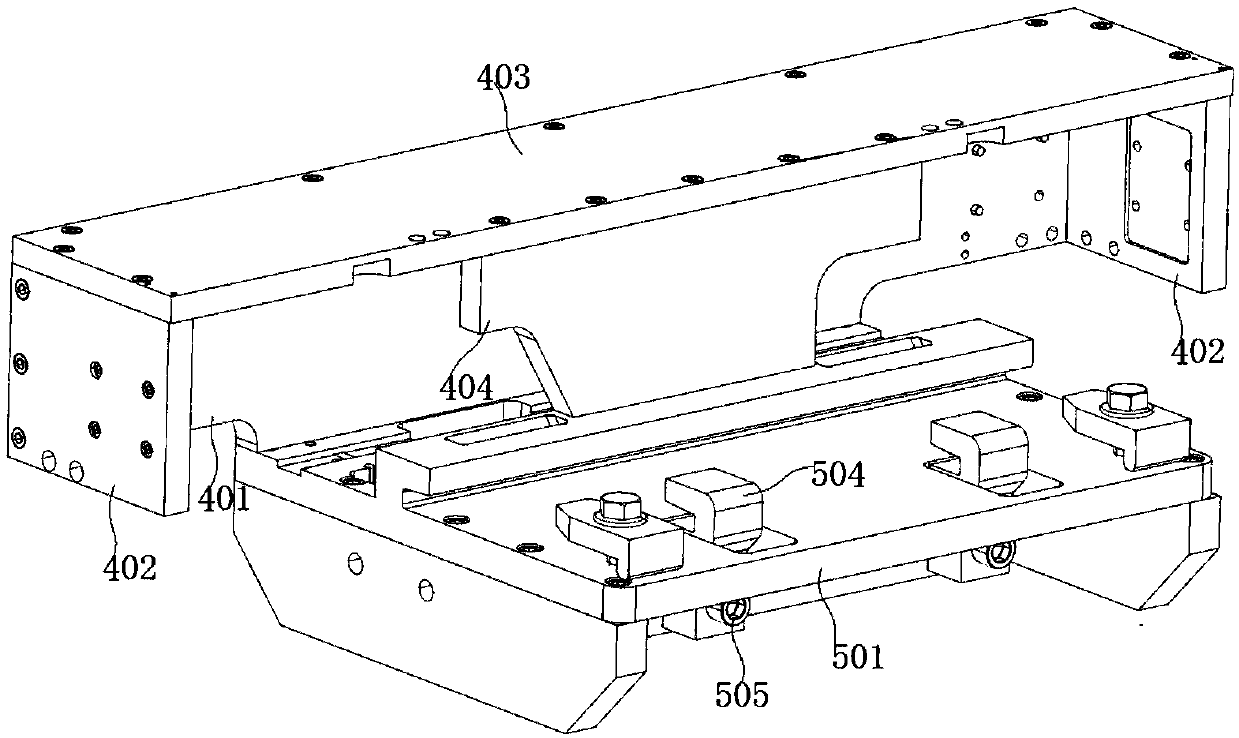

[0045] combine Figure 1-Figure 5 , a device for accurately detecting wheel tread scratches and out-of-roundness in this embodiment includes a pedal 2, a sliding plate 3 and a fixed plate assembly 4 installed on the inner side of the track 1 and parallel to each other, the sliding plate 3 and the pedal 2 and the fixed plate assembly 4 are connected by a slide rail mechanism, and an elastic element 8 is connected between the sliding plate 3 and the pedal 2;

[0046] The train wheel includes a tread portion and a rim portion. The tread is out of round due to long-term contact and wear of the track, but the rim is still a standard circle without contact with other objects. Therefore, when the wheel tread is in contact with the rail at different positions, the distance from the rim apex to the top surface of the rail is not the same. In this embodiment, a pedal 2 is installed on the rail. When the wheel passes by, the top surface of the pedal 2 is always in contact with the apex ...

Embodiment 2

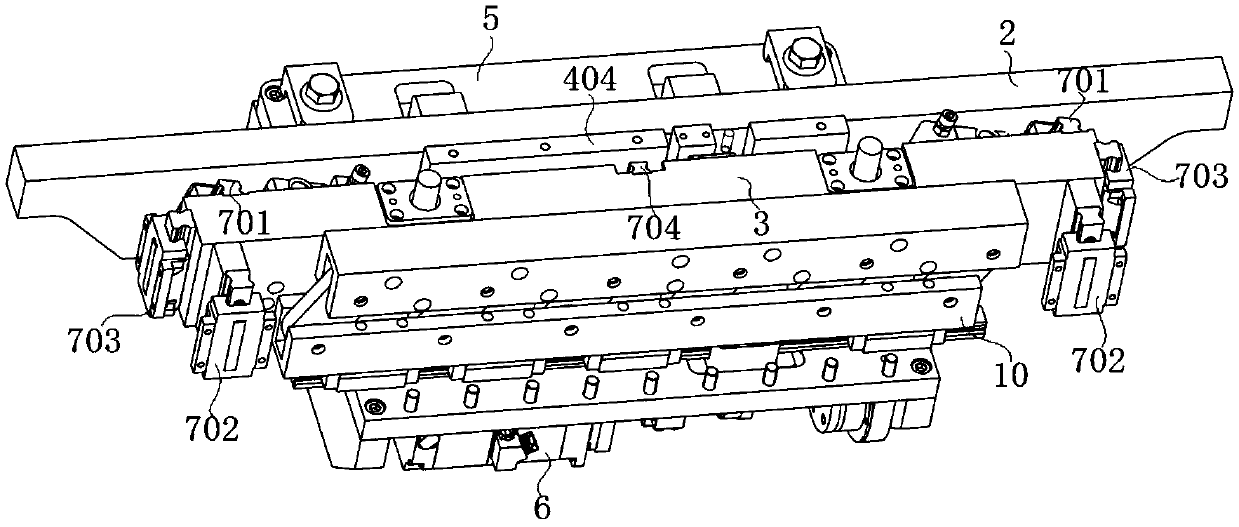

[0051] A device for accurately detecting wheel tread scratches and out-of-roundness in this embodiment, its structure is basically the same as that of Embodiment 1, the difference mainly lies in: image 3 , Figure 5 As shown, the swing link transmission mechanism 10 of the present embodiment includes an upper slider fixing plate 1001, a swing link 1002 and a lower slider fixing plate 1003, wherein the two ends of several parallel swing links 1002 are respectively connected with the upper slider fixing plate 1001, The lower slider fixed plate 1003 is rotated and connected to form a parallelogram mechanism (the two ends of the swing rod 1002 in this embodiment are respectively equipped with bearings, and the upper slider fixed plate 1001 and the lower slider fixed plate 1003 are respectively fixed with the above-mentioned bearings. Matching bearing pins, thereby realizing that the swing link 1002 is connected to the rotation between the upper slider fixed plate 1001 and the low...

Embodiment 3

[0053] A device for accurately detecting wheel tread scratches and out-of-roundness in this embodiment is basically the same in structure as Embodiment 2, the main difference is that the swing link transmission mechanism 10 of this embodiment is connected with the bottom plate through the slide rail mechanism. 5 can be slidably connected, and the bottom plate assembly 5 is fixedly installed on the bottom of the track 1 , and the fixed plate assembly 4 and the driving mechanism 6 are both installed on the bottom plate assembly 5 . Specifically, the slide mechanism includes a slider 1004 and a guide rail 1005, wherein the guide rail 1005 is fixedly installed on the bottom plate assembly 5, and the slider is fixedly installed on the bottom of the lower slider fixing plate 1003 at intervals. When the driving mechanism 6 is working, The lower slider fixing plate 1003 is driven to move horizontally along the linear guide rail 1005 , which is beneficial to ensure the stability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com